Preparation method of abx3 type all-inorganic perovskite nanocrystal

An inorganic calcium and nanocrystal technology, applied in inorganic chemistry, nanotechnology, nano-optics, etc., can solve the problems of high price, unsuitable for industrial production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: CsPbCl 3 Preparation of perovskite quantum dots.

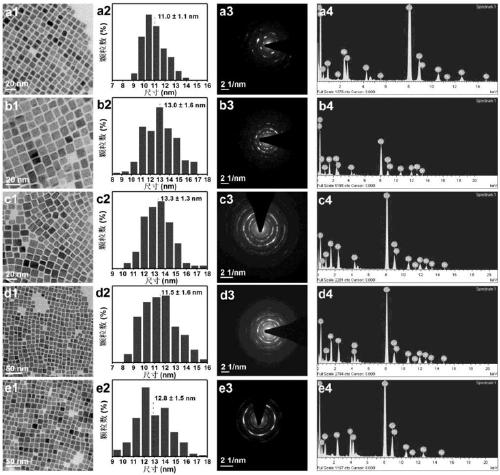

[0065] Weigh 0.5mmol lead acetate and 0.1mmol cesium carbonate, then add 1mL oleic acid, 1mL oleylamine, 1mL tri-n-octylphosphine and 10mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 10 minutes to form a transparent solution A, then Raise the temperature to 180°C; quickly inject 124 μL of hydrochloric acid into solution A, keep warm for 10 seconds, and quickly cool it in an ice bath (cooling rate is about 10-15°C / second) to room temperature; first centrifuge and then use 10mL cyclohexane and 10mL acetone Wash once, and disperse the precipitate in 30mL cyclohexane to obtain CsPbCl with a particle size of about 11.0nm 3 Perovskite quantum dots.

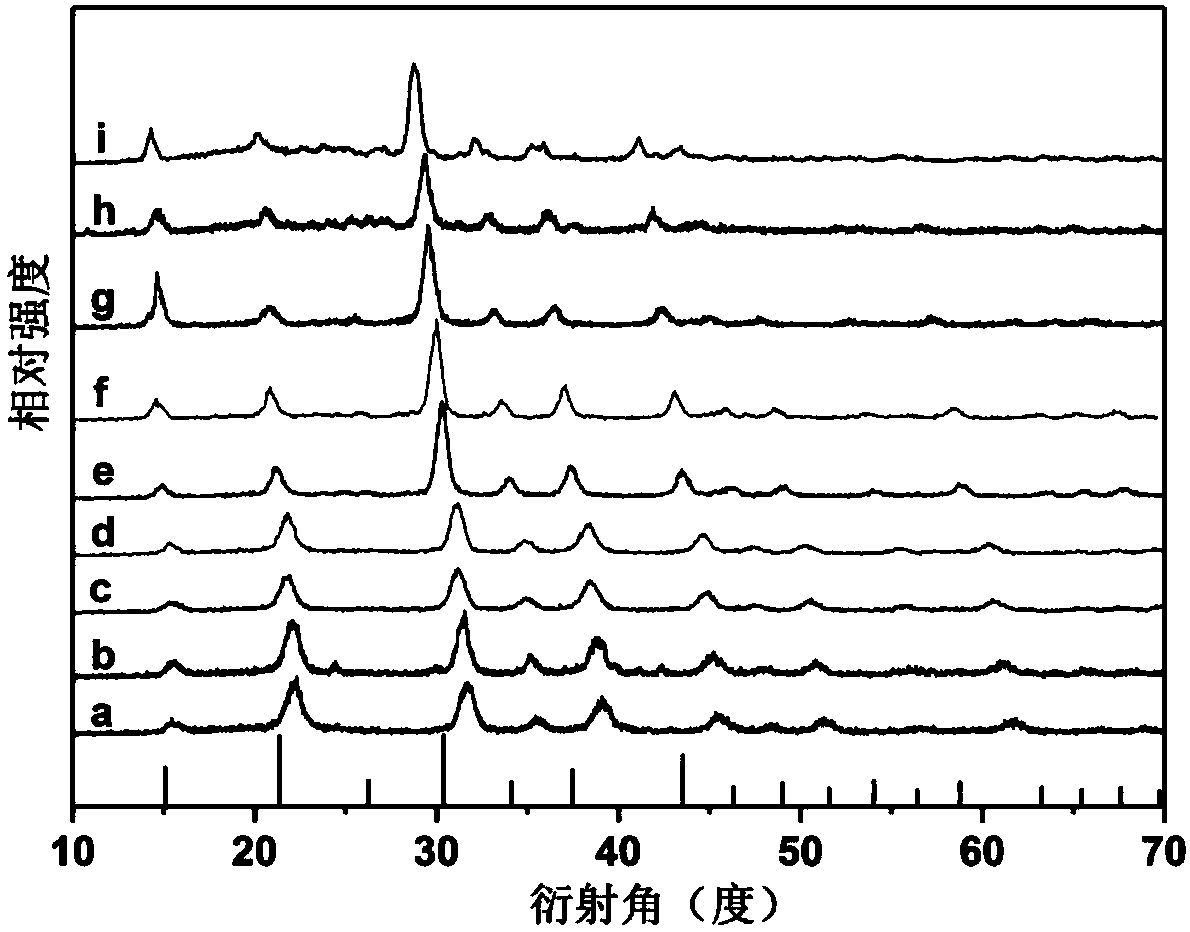

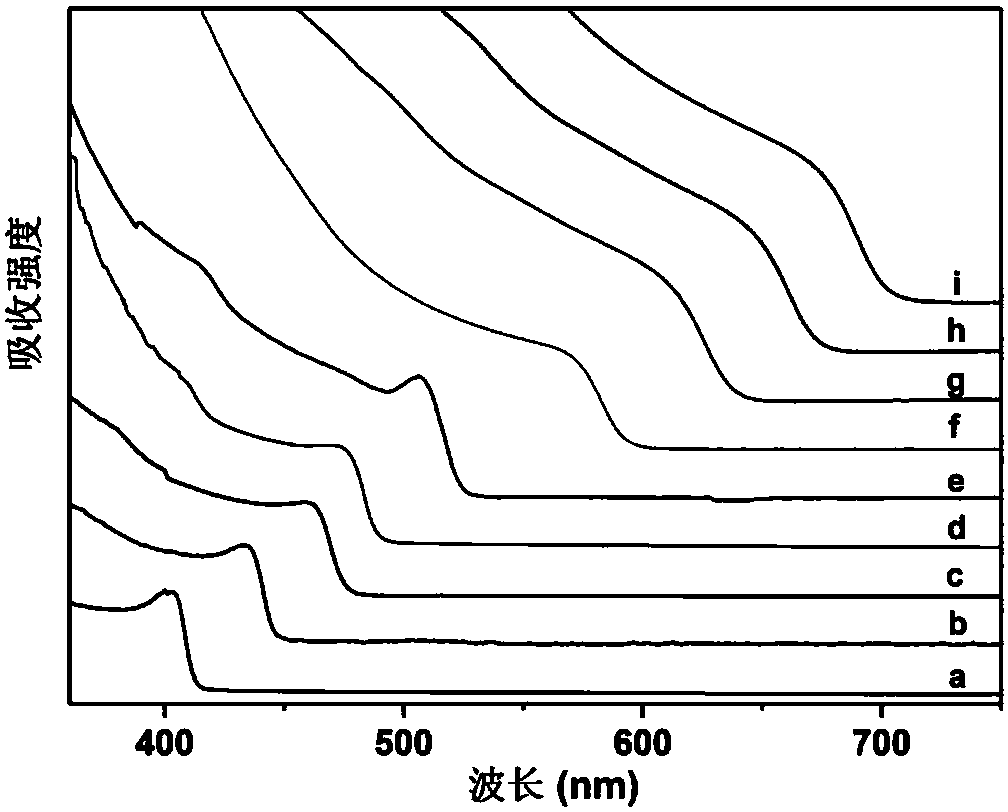

[0066] X-ray powder diffraction pattern ( figure 1 a) shows that the quantum dots have good crystallinity, and the position and relative intensity of the diffraction peaks are the same as those of the cubic phase CsPbCl 3 The PDF standard card ...

Embodiment 2

[0067] Example 2: CsPbCl 2 Preparation of Br perovskite quantum dots.

[0068] Weigh 0.5mmol lead oxalate and 0.2mmol cesium acetate, then add 1mL oleic acid, 1mL oleylamine, 1.5mL tri-n-octylphosphine and 20mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 20 minutes to form a transparent solution A , and then warmed up to 200°C; quickly inject 83 μL of hydrochloric acid and 58 μL of hydrogen bromide into solution A, keep warm for 5 seconds, and cool down to room temperature; centrifuge and wash once with 10 mL of cyclohexane and 10 mL of acetone, and remove the precipitate Disperse in 30mL cyclohexane to obtain CsPbCl with a particle size of about 15.0nm 2 Br perovskite quantum dots.

[0069] X-ray powder diffraction pattern ( figure 1 b) shows that the quantum dots have good crystallinity, and the position and relative intensity of the diffraction peaks are the same as those of the cubic phase CsPbCl 3 and CsPbBr 3 The PDF standard cards (JCPDS NO.75-...

Embodiment 3

[0070] Example 3: CsPbCl 1.5 Br 1.5 Preparation of perovskite quantum dots.

[0071] Weigh 0.5mmol lead acetate and 0.05mmol cesium carbonate, then add 0.5mL oleic acid, 0.5mL oleylamine and 6mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 30 minutes to form a transparent solution A, then heat up to 190°C; Quickly inject 62 μL of hydrochloric acid and 87 μL of hydrogen bromide into solution A, keep warm for 5 seconds, and quickly cool to room temperature in an ice-water bath; centrifuge and then wash once with 5 mL of cyclohexane and 5 mL of acetone, and disperse the precipitate in a 30 mL ring In hexane, CsPbCl with a particle size of about 13.0nm was obtained 1.5 Br 1.5 Perovskite quantum dots.

[0072] X-ray powder diffraction pattern ( figure 1 c) shows that the quantum dots have good crystallinity, and the position and relative intensity of the diffraction peaks are the same as those of the cubic phase CsPbCl 3 and CsPbBr 3 The PDF standard card...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com