Microbial electrochemical in-situ biogas desulfurization method

A microbial electrochemistry and biogas desulfurization technology, applied in the field of in-situ biogas desulfurization, can solve problems such as electrode passivation, reduce the floor space, simplify the biogas desulfurization and purification system, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

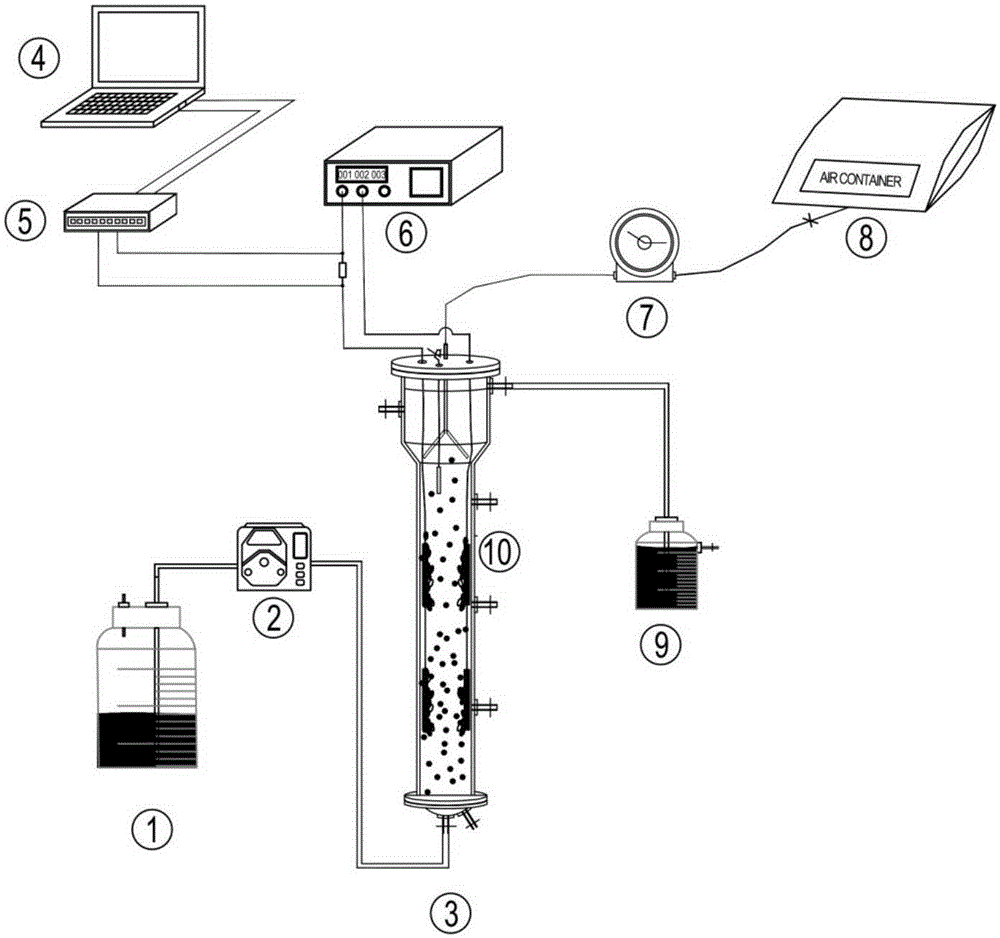

Method used

Image

Examples

Embodiment 1

[0035] (1) Anode sulfur oxidation biofilm domestication

[0036]Construct a double-chamber microbial electrolytic cell, the anode is composed of two graphite plates, the size of each graphite plate electrode is 8cmx4cm, and the composition of the anode culture solution is 0.25g / LNH 4 Cl,0.5g / LNaH 2 PO 4 ,2.0g / LNaHCO 3 ,0.25g / L Acetate,5.0mMNa 2 S. The anode chamber was inoculated with Desulfuromonas, the anode potential was set to 0.3V (VsAg / AgCl) with a potentiostat, and 0.25g / LNH was added to the cathode chamber 4 Cl, 0.5g / LNaH 2 PO 4 , 2.0g / LNaHCO 3 The culture solution; observe the change of current and detect the content of sulfide and sulfate at the same time, when more than 90% of sulfide is converted into sulfate, change the solution until the sulfur conversion and current change show a periodic law, and the anodic sulfur oxidation biofilm Domestication was successful.

[0037] (2) Build electrodes

[0038] Transfer the two domesticated sulfur oxidation biofi...

Embodiment 2

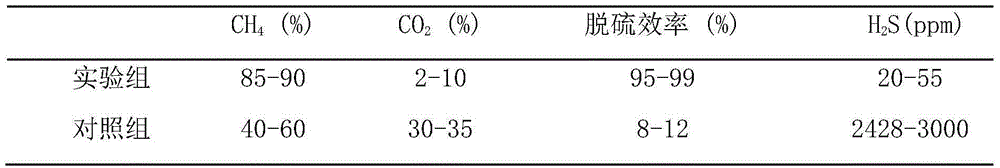

[0045] The method of this example is the same as Example 1, the difference is that the applied voltage is controlled at 0.9V, and the anaerobic reactor continuously flows into the water to treat pig farm breeding wastewater, HRT=8h, and the data of the experimental group and the control group are respectively as follows:

[0046] Experimental group and control group data of table 2 embodiment 2

[0047]

[0048] It can be seen from the experimental data that the methane content of the experimental group can reach more than 80%, and the gas percentage is the volume percentage (V / V).

Embodiment 3

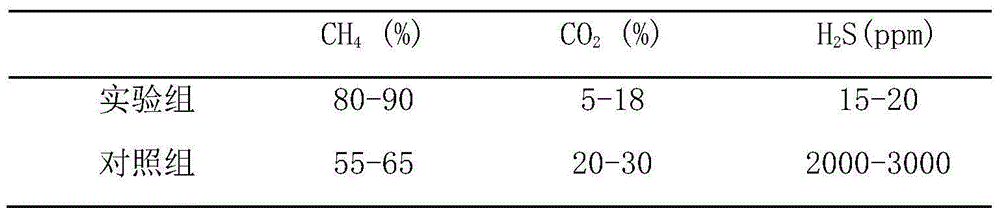

[0050] The method of this example is the same as Example 2, and the difference is that the anaerobic reactor directly processes the fresh leachate of the garbage transfer station. Under the continuous flow operation condition (HRT=8h), the data of the experimental group and the matched group are respectively as follows:

[0051] Experimental group and control group data of table 3 embodiment 3

[0052]

[0053] It can be seen from the experimental data that the methane content of the experimental group is much higher than that of the control group, and the hydrogen sulfide content in the biogas is lower than 10ppm, and the gas percentage is volume percentage (V / V).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com