Desulfurization slag system of ultralow-sulfur raw steel and preparation and application methods thereof

An application method, desulfurization slag technology, applied in the direction of process efficiency improvement, electric furnace, furnace, etc., can solve problems such as narrowing the technical gap, and achieve the effect of narrowing the technical gap and effective desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

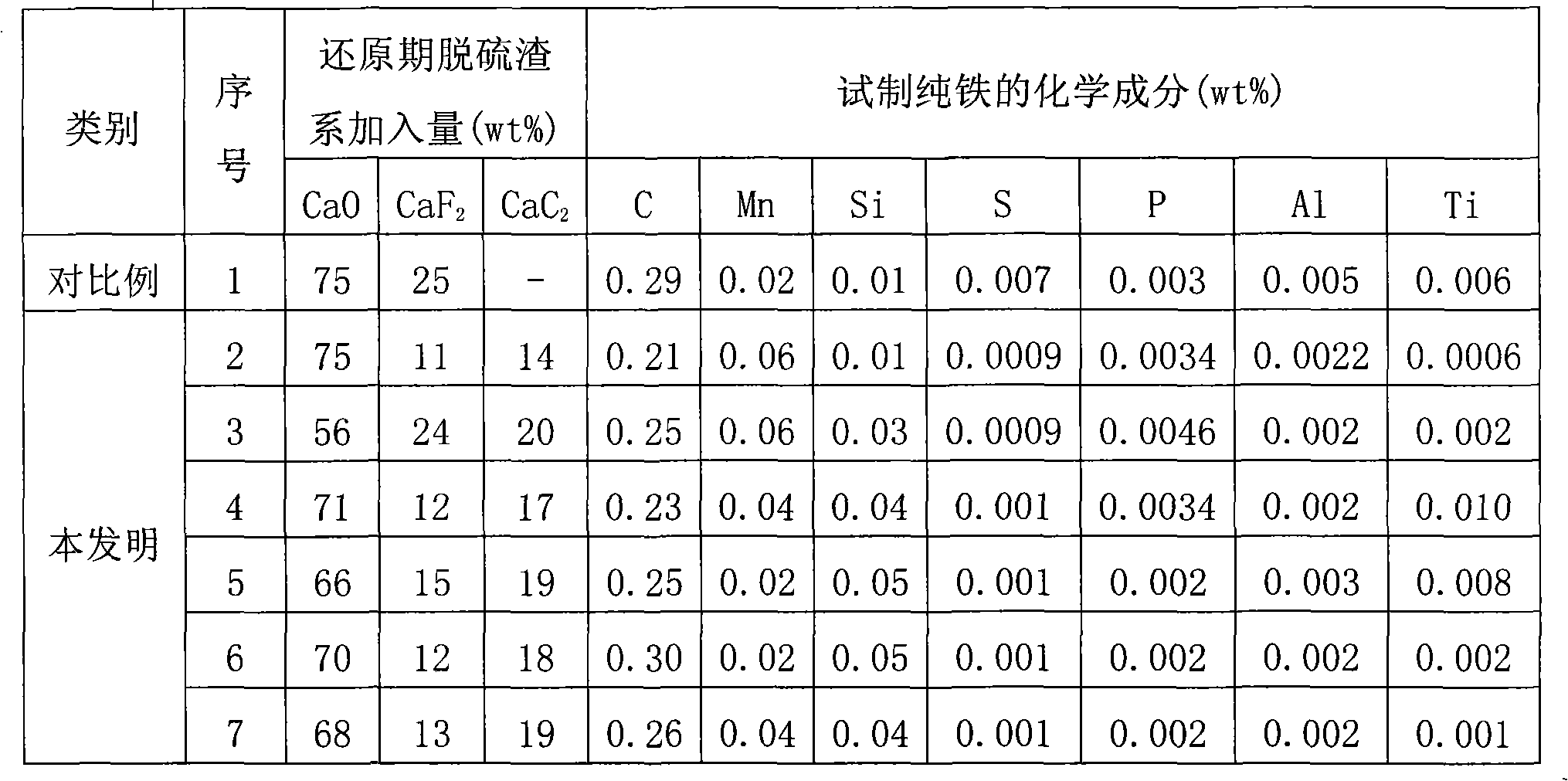

[0062] The chemical composition of the desulfurization slag system of the ultra-low sulfur raw material steel of the present invention includes: 55-75wt% CaO, 10-25wt% CaF 2 And 10~20wt% CaC 2 . When preparing, choose CaF 2 ≥90wt% high-purity super-grade fluorspar, CaO≥90wt% active lime and ensure that it is in a dry state and the particle size is 2 The calcium carbide is mixed evenly.

[0063] When using the desulfurization slag system of the above-mentioned ultra-low sulfur raw material steel, the process route of EF furnace + LFV furnace is adopted, and the specific description is as follows:

[0064] (1) EF furnace: After the furnace charge is fully melted, add active lime and fluorite in batches, and blow oxygen for oxidation treatment. When P≤0.002wt%, Si≤0.05wt% and Mn≤0.05wt%, the oxidation slag is scraped out, And the more thorough the slag removal, the better; the reduction is divided into 2-3 batches, and the ternary component slag is mixed evenly and then added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com