Alpha-alumina support for silver catalyst for olefin epoxidation and preparation method thereof

A technology of alumina carrier and silver catalyst, which is applied in the direction of catalyst carrier, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low selectivity and achieve the effect of selectivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] a) Preparation of carrier

[0056] 50-500 mesh, α-trihydrate Al 2 o 3 338 g of pseudo-Al monohydrate larger than 200 mesh with a silicon content of 780 ppm (by mass of silica) and a magnesium content of 32 ppm (by mass) 2 o 3 145g, petroleum coke 0g, 2g finely ground barium sulfate, NH 4 Put F7g into a mixer and mix evenly, transfer it to a kneader, add 0.12 liters of dilute nitric acid (nitric acid: water = 1:3, weight ratio), and knead it into a paste that can be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry it at 80-120°C for more than 2 hours to reduce the free moisture content to below 10%.

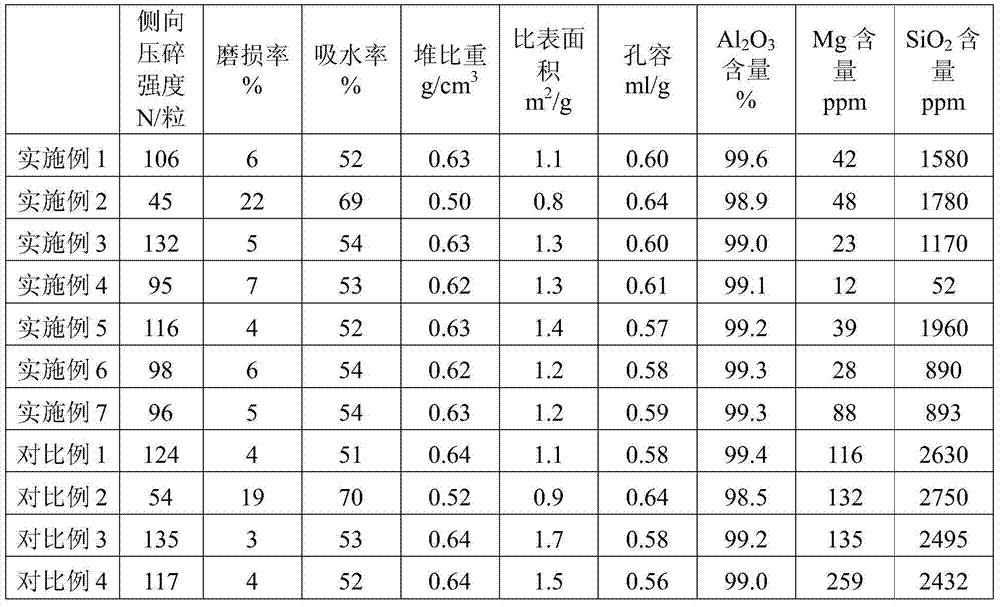

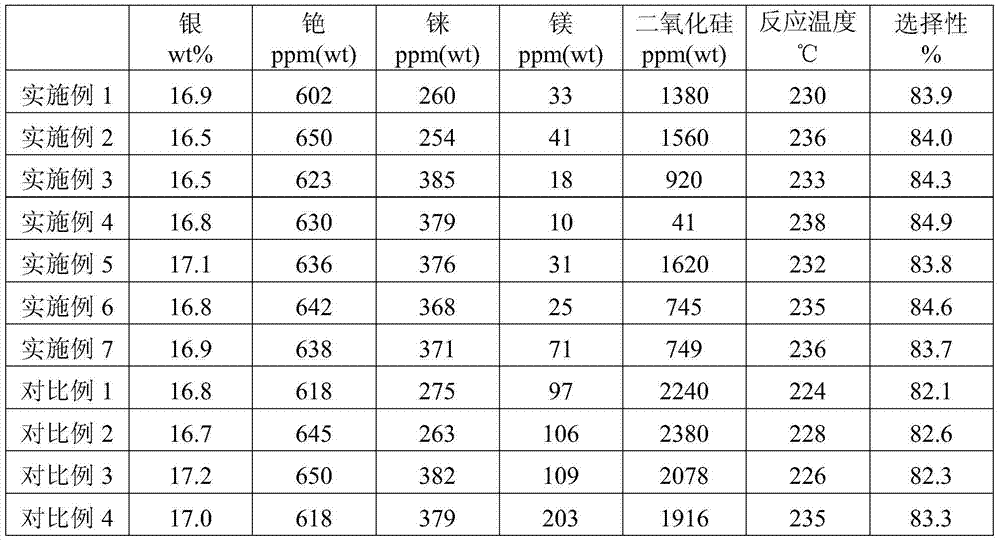

[0057] Put the above-mentioned five-hole column into a bell kiln, raise it from room temperature to 1350°C in about 30 hours, and keep the temperature constant for 6 hours to obtain white α-Al 2 o 3 Carrier samples. The performance data of the tested carriers are shown in Table 1.

...

Embodiment 2

[0069] With embodiment 1, difference is to add the petroleum coke of 41g. The data of the prepared carrier is shown in Table 1; the data of the silver catalyst prepared using the carrier of this embodiment and its catalytic performance data are shown in Table 2.

Embodiment 3

[0071] The same as in Example 1, the difference is: the use of α-trihydrate Al with a silicon content of 890ppm (by mass) and a magnesium content of 18ppm (by mass) 2 o 3 212 g of pseudo-Al monohydrate with a silicon content of 1720 ppm (by mass of silica) and a magnesium content of 23 ppm (by mass) 2 o 3 192g and add Vaseline 10g, NH 4 F7g, 2g of finely ground barium sulfate; the five-hole column was kept at a constant temperature for 12h between room temperature and 1200°C; when preparing the impregnating solution, add 2.2g of cesium sulfate, 1.4g of strontium acetate and 0.6g of perrhenic acid instead of adding 2.2g cesium sulfate, 2.6g barium acetate, 0.3g lithium sulfate and 0.9g perrhenic acid; the impregnated carrier was heated at 220°C. The data of the prepared carrier is shown in Table 1; the data and catalytic performance data of the silver catalyst prepared using the carrier of this embodiment are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com