Method for recovering aluminum from alumina production waste red mud

A waste and alumina technology, applied in the direction of aluminum sulfur compounds, aluminum sulfate, etc., can solve the problems of land occupation, environmental pollution, safety hazards, waste of resources, etc., and achieve the effect of easy production, large demand, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

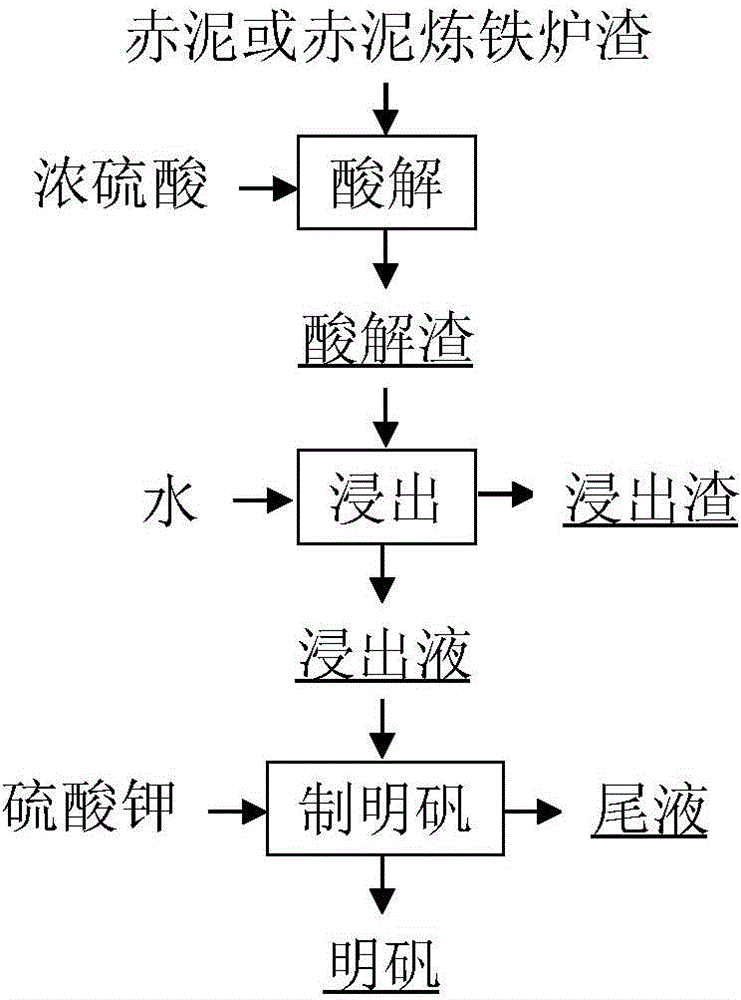

[0014] The method for recovering aluminum from alumina production waste red mud described in the present invention, the raw material used in this embodiment is red mud, includes the following steps:

[0015] 1. According to the liquid-solid volume mass ratio of 0.6:1, the red mud and industrial concentrated sulfuric acid are prepared into pulp, and the acid hydrolysis is obtained with stirring and acid hydrolysis for 60 minutes in a heated and stirred container at 250°C for 60 minutes.

[0016] 2. Add water to the acid hydrolysis slag according to the liquid-solid volume mass ratio of 3:1 to adjust the slurry, stir and leaching reaction at 80°C for 90 minutes, and separate the leaching slurry from solid and liquid with a filter press to obtain leaching liquid and leaching residue.

[0017] 3. Add potassium sulfate 1.2 times the theoretical value according to the aluminum content in the leaching solution, stir and react in a container with cooling and stirring for 90 minutes, th...

Embodiment 2

[0020] Another example of the method for recovering aluminum from alumina production waste red mud according to the present invention, the raw material used in this embodiment is red mud, including the following steps:

[0021] 1. According to the liquid-solid volume mass ratio of 1.6:1, red mud and industrial concentrated sulfuric acid are used to prepare ore pulp, and the acid hydrolysis is stirred and acidified for 60 minutes in a heated and stirred container at 200°C.

[0022] 2. Add water to the acid hydrolysis slag according to the liquid-solid volume mass ratio of the original red mud amount 4:1, stir and leaching reaction at 60°C for 120 minutes, and separate the leaching slurry from solid to liquid with a filter press to obtain leaching liquid and leaching residue .

[0023] 3. Add potassium sulfate 1.2 times the theoretical value according to the aluminum content in the leaching liquid, stir and react in a container with cooling and stirring for 90 minutes, the end p...

Embodiment 3

[0026] Another example of the method for recovering aluminum from alumina production waste red mud according to the present invention, the raw material used in this embodiment is red mud ironmaking slag, including the following steps:

[0027] 1. Red mud ironmaking slag and industrial concentrated sulfuric acid are used to prepare ore pulp with a liquid-to-solid volume-to-mass ratio of 1:1, and then stir and acidolyze in a heated and stirred container at 150°C for 30 minutes.

[0028] 2. Add water to the acid hydrolysis slag according to the ratio of liquid to solid volume and mass of the original slag of 7:1, stir and leaching reaction at 80°C for 120 minutes, and separate the leaching slurry from solid to liquid with a filter press to obtain leaching liquid and leaching slag.

[0029] 3. Add potassium sulfate 1.2 times the theoretical value according to the aluminum content in the leaching solution, stir and react in a container with cooling and stirring for 60 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com