Red mud on-line comprehensive treatment method

A technology of comprehensive treatment and treatment method, applied in the direction of sustainable waste treatment, cement production, solid waste management, etc., can solve the problems of high energy consumption, high liquid-solid ratio, large acid consumption, etc., and achieve simple process and high activity , The effect of high dealkalization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

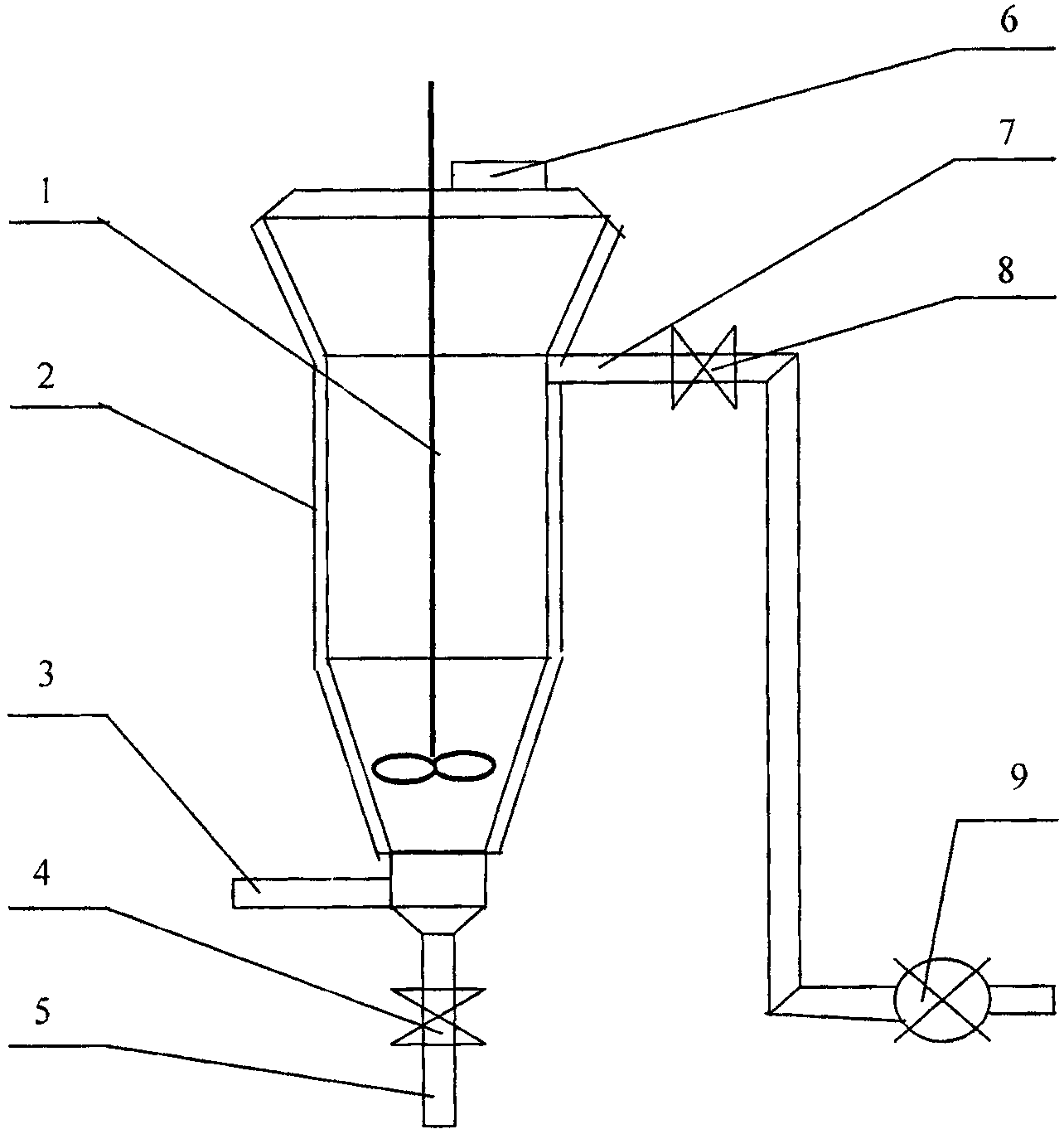

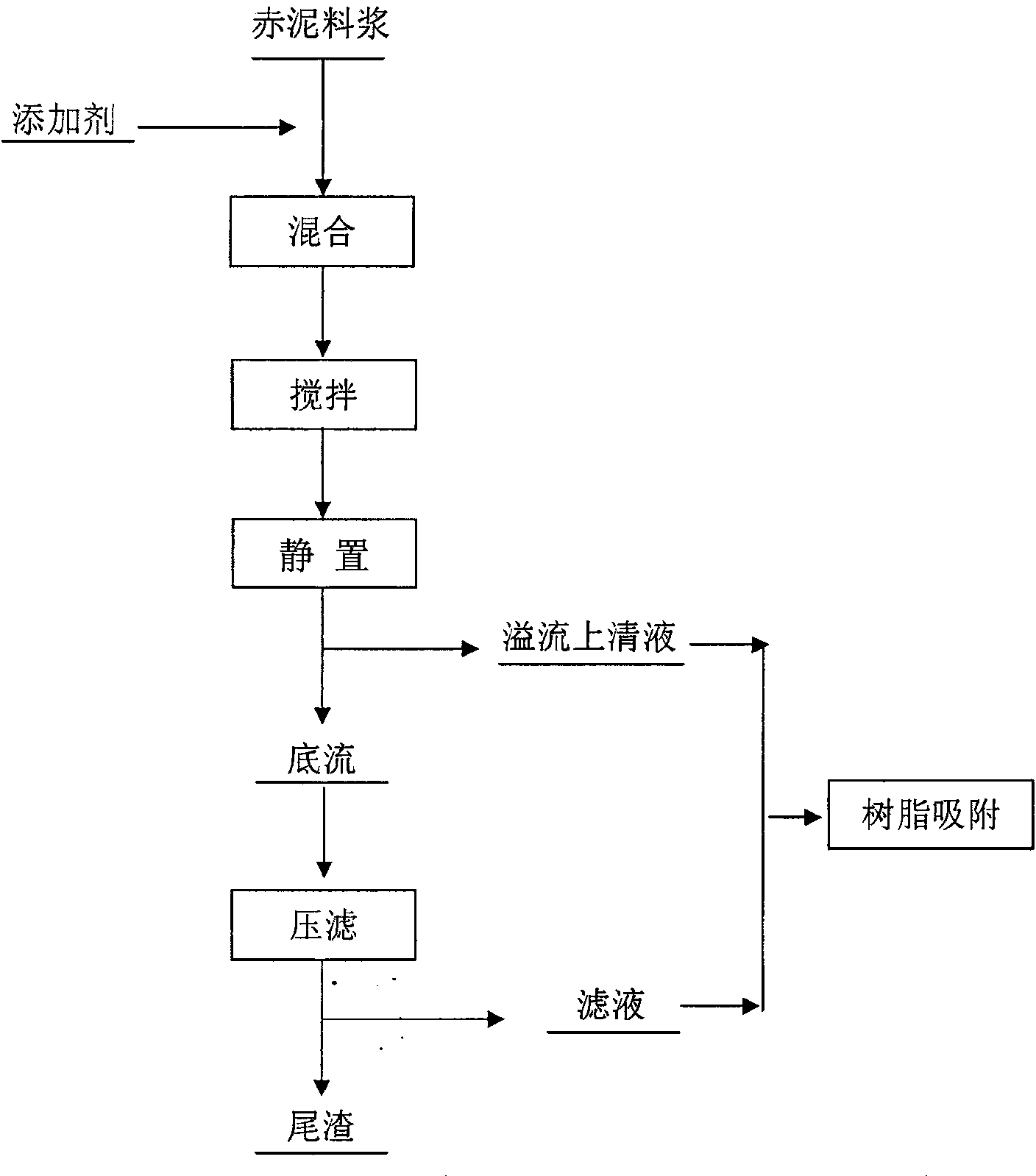

[0024] The red mud slurry is directly discharged into the stirring device through the slurry inlet without cooling, concentrating and filtering, and then calcium carbide slag with a mass fraction of 20~30% is added through the feeding port, and the stirring intensity is 100~ 250r / min, stirring time is 60-180min, after stirring, let it stand for 5-10min, discharge the supernatant from the overflow pipe of the stirring device, and discharge the underflow to the filter press for pressure filtration, the red mud dealkalization rate is 82~ 95%, the filtrate and supernatant are mixed and adsorbed by 001×7 resin for the next step of alkali recovery operation, the calcium content in red mud tailings is 25~35%, and the building materials are prepared.

Embodiment 2

[0026] The red mud slurry is directly discharged into the stirring device through the slurry inlet without cooling, concentration and filtration, and then calcium carbide slag with a mass fraction of 15~25% is added through the feeding port, and the stirring intensity is 150~ 300r / min, stirring time is 120-240min, after stirring, let it stand for 5-10min, discharge the supernatant from the overflow pipe of the stirring device, and discharge the underflow to the filter press for pressure filtration, the red mud dealkalization rate is 78~ 90%, the filtrate and supernatant are mixed and adsorbed by 001×7 resin for the next step of alkali recovery operation. The calcium content in the red mud tailings is 22~32%, and the building materials are prepared.

Embodiment 3

[0028] The red mud slurry is directly discharged into the stirring device through the slurry inlet without cooling, concentration and filtration, and then calcium carbide slag with a mass fraction of 10~20% is added through the feeding port, and the stirring intensity is 200~ 400r / min, stirring time is 180-300min, after stirring, let it stand for 5-10min, discharge the supernatant from the overflow pipe of the stirring device, and discharge the underflow to the filter press for pressure filtration, the red mud dealkalization rate is 75~ 85%, the filtrate and supernatant are mixed and adsorbed by 001×7 resin for the next step of alkali recovery operation, the calcium content in red mud tailings is 18~30%, and the building materials are prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com