Method for performing dealkalization on Bayer process red mud by using fluorgypsum

A technology of Bayer red mud and fluorogypsum, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of complex operation, long dealkalization time, and high cost of dealkalization, and achieve The process is simple, the cost is low, and the effect that is difficult to handle is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

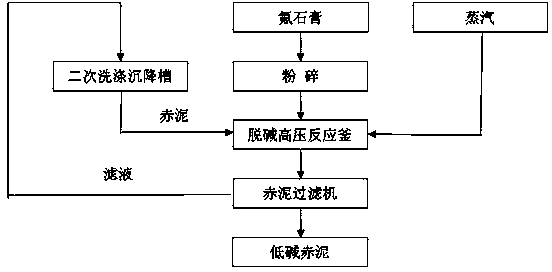

Image

Examples

Embodiment 1

[0033] The alkali content of Bayer red mud is 4.66%, the particle size is 180um, and the liquid-solid ratio is 8 to make red mud slurry, add 35% fluorine gypsum gypsum, and conduct steam dealkalization reaction in the high-pressure reactor. The reaction temperature was 90° C., the reaction pressure was 1.2 MPa, and the mixture was stirred for 90 minutes at a stirring speed of 200 rpm. After the red mud slurry is filtered, washed and dried, the content of alkali in the sintered red mud is analyzed to be 0.96%.

Embodiment 2

[0035] The alkali content of Bayer red mud is 4.28%, the particle size is 200um, and the liquid-solid ratio (ml / g) is 9 to prepare red mud slurry, add 40% fluorine gypsum, and heat in a high-pressure reactor by feeding steam dealkalization reaction. The reaction temperature was 100° C., the reaction pressure was 1.6 MPa, and the stirring rate was 180 rpm for 90 min. After the red mud slurry was filtered, washed and dried, the content of alkali in the red mud by the sintering method was analyzed to be 0.86%.

Embodiment 3

[0037] The alkali content of Bayer red mud is 6.28%, the particle size is 180um, and the liquid-solid ratio is 8.5 to make red mud slurry, add 35% fluorine gypsum, and carry out heating dealkalization reaction by passing steam into the reaction vessel. The reaction temperature is 70° C., the reaction pressure is 1.0 MPa, and the stirring rate is 180 rpm for 80 min. After the red mud slurry is filtered, washed and dried, the content of alkali in the sintered red mud is analyzed to be 0.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com