Comprehensive utilization method of red mud

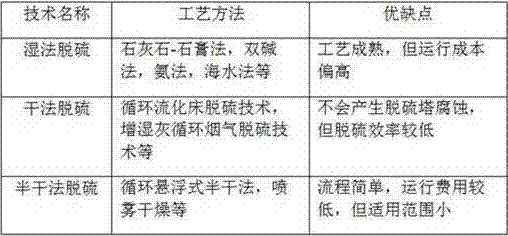

A technology for red mud and red mud slag, applied in separation methods, chemical instruments and methods, cement production, etc., can solve problems such as seldom research, and achieve the effects of low firing temperature, saving desulfurizer costs, and less heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. Preparation of red mud-calcium dealkalization agent mixed pulp:

[0030] Inject the sintered red mud and calcium oxide (calcium dealkalization agent) into the red mud-calcium dealkalizer mixed slurry preparation tank according to the composition ratio of 85:15, install stirring devices at both ends of the preparation tank, add water and stir Uniform, prepared into a red mud-calcium dealkalization agent mixed slurry with a liquid-solid ratio of 9:1 (kg / kg);

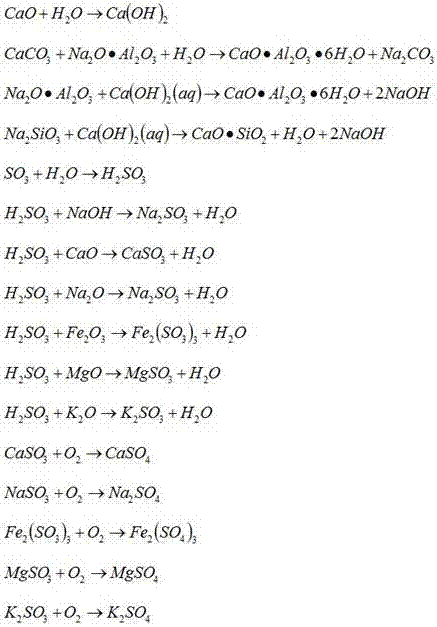

[0031] b. Desulfurization of red mud-calcium dealkalization agent mixed pulp:

[0032] Import the red mud-calcium dealkalization agent mixed slurry made in step a into the storage tank, and use the slurry circulation pump to send the red mud-calcium dealkalization agent mixed slurry in the storage tank to the top of the desulfurization tower and pass through the top of the tower The spraying device is sprayed into the desulfurization tower, and the SO 2 Flue gas (sulfur dioxide content is 1600mg / Nm 3 ) enters ...

Embodiment 2

[0039] The steps are basically the same as in Example 1, the difference is that:

[0040] In step a: the calcium dealkalization agent used is calcium carbonate, the red mud used is Bayer red mud, and in the preparation of red mud-calcium dealkalizer mixed slurry, the component ratio of red mud and calcium carbonate is 90: 10; The liquid-solid ratio of red mud-calcium dealkalization agent mixed slurry is 7:1;

[0041] In step b: in the process of flue gas desulfurization, the red mud-calcium dealkalization agent mixed slurry is mixed with SO-containing 2 The liquid-gas ratio of flue gas is 16:1 (L / m 3 ). SO before desulfurization 2 The sulfur dioxide content in the flue gas is 1700mg / Nm 3 , SO after desulfurization 2 The sulfur dioxide content in the flue gas is 89mg / Nm 3 .

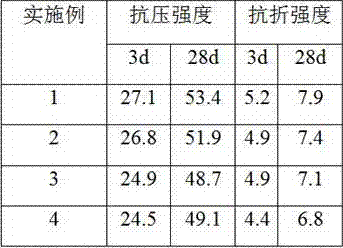

[0042] In step d, take 48.7% of desulfurization red mud slag, 43% of limestone, 6% of sandstone, and 2.3% of fly ash according to the mass, mix them evenly, and put them in a pulverizer to grind unt...

Embodiment 3

[0045] The steps are basically the same as in Example 1, the difference is that:

[0046] In step a: the calcium dekalization agent used is calcium hydroxide, the red mud used is a combined process red mud, and in the preparation of red mud-calcium dekalization agent mixed slurry, the composition ratio of red mud and calcium hydroxide is 95:5; the liquid-solid ratio of red mud-calcium dealkalization agent mixed slurry is 5:1;

[0047] In step b: in the flue gas desulfurization process, the red mud-calcium dealkalization agent mixed slurry with a liquid-solid ratio of 5:1 and SO2-containing 2 The liquid-to-gas ratio of the flue gas is 12:1 (L / m 3 ). SO before desulfurization 2 The sulfur dioxide content in the flue gas is 1800mg / Nm 3 , SO after desulfurization 2 The sulfur dioxide content in the flue gas is 97mg / Nm 3 .

[0048] In step d, 50.1% of desulfurization red mud residue, 41% of limestone, 6% of sandstone, and 2.9% of fly ash were taken by mass, mixed evenly, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com