Method for producing active calcium silicate by using fly ash desilication mother solution

A technology of fly ash and calcium silicate, applied in the direction of silicate, alkaline earth metal silicate, etc., to achieve the effect of remarkable economic benefit, low production cost and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

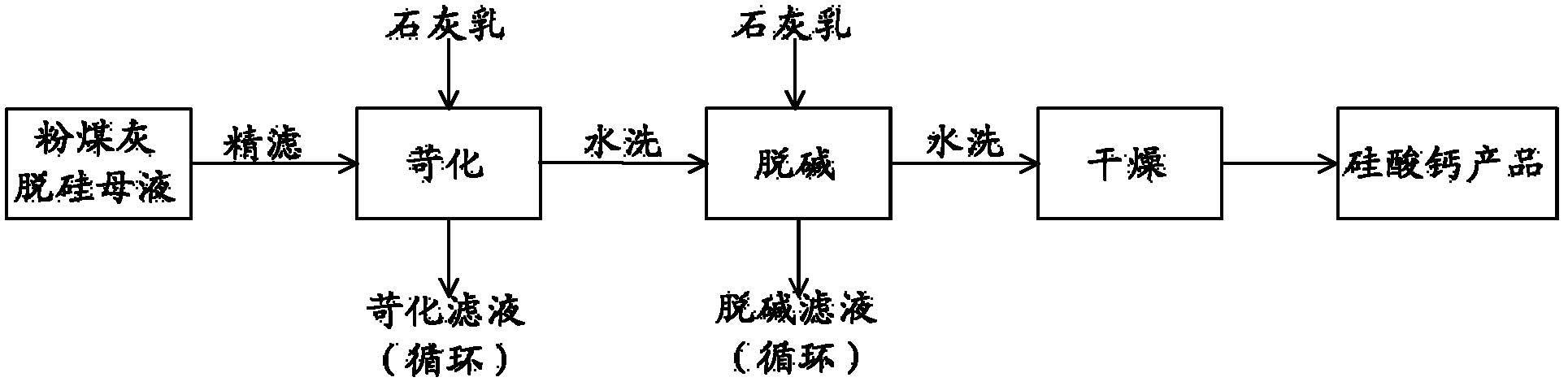

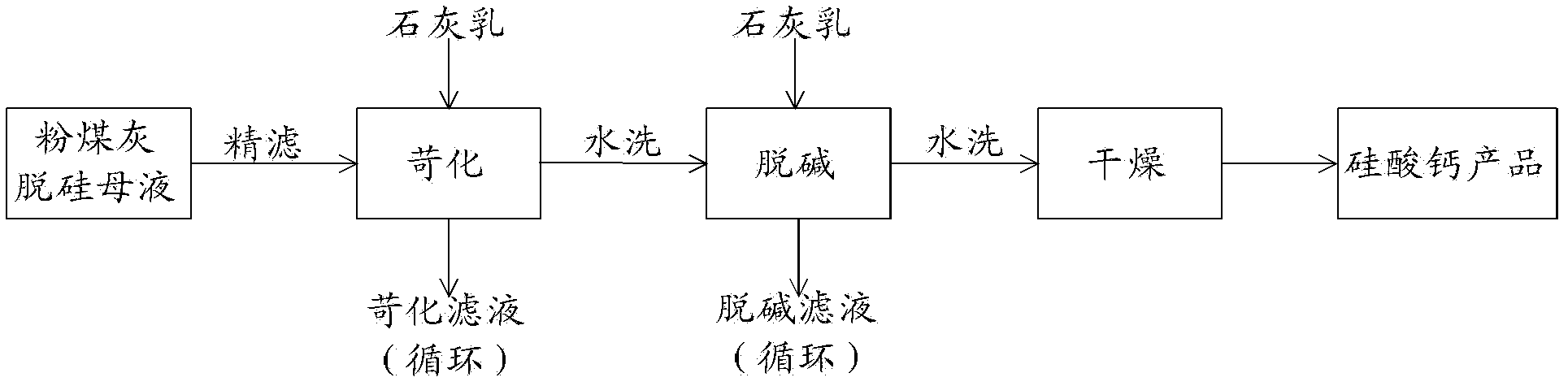

Method used

Image

Examples

Embodiment 1

[0034] Move the desiliconization mother liquor in the process of producing alumina from fly ash into a vertical leaf filter for fine filtration to remove suspended solids in the fly ash desilication mother liquor; : 1 mixed evenly to prepare milk of lime; the milk of lime and the desiliconized semen of fly ash were compared with calcium to silicon (the CaO in the milk of lime and the SiO in the desiliconized semen of fly ash 2 The ratio of the amount of substance) is 0.95 and mixed evenly, moved into the causticization tank, and stirred at a stirring rate of 150r·min -1 1. Carry out causticizing reaction at a reaction temperature of 95°C for 1 hour; move the slurry after the causticizing reaction into a filter for solid-liquid separation to obtain solid-phase calcium silicate slag and liquid-phase sodium hydroxide solution; process water and calcium silicate The slag is mixed evenly according to the liquid-solid ratio of 2:1, moved into the washing tank, and stirred at a stirr...

Embodiment 2

[0036] Move the desiliconization mother liquor in the process of producing fly ash to mullite into a vertical leaf filter for fine filtration to remove suspended solids in the fly ash desilication mother liquor; process water and calcium hydroxide in a liquid-solid ratio of 3:1 mixed evenly to prepare milk of lime; milk of lime and desiliconized semen from fly ash according to the ratio of calcium to silicon (CaO in milk of lime and SiO in desiliconized semen from fly ash 2 The ratio of the amount of substance) is 1.0 and mixed evenly, moved into the causticization tank, and stirred at a stirring rate of 150r·min -1 1. Carry out causticizing reaction at a reaction temperature of 95°C for 1.5h; move the slurry after the causticizing reaction into a filter for solid-liquid separation to obtain solid-phase calcium silicate slag and liquid-phase sodium hydroxide solution; process water and silicic acid Calcium slag is mixed evenly according to the liquid-solid ratio of 2:1, moved ...

Embodiment 3

[0038] Transfer the secondary desiliconization mother liquor in the process of producing fly ash to mullite into a vertical leaf filter for fine filtration to remove suspended solids in the fly ash desilication mother liquor; process water and calcium hydroxide by liquid-solid The ratio is 3:1 and mixed evenly to prepare lime milk; the lime milk and fly ash desilication semen are mixed according to the calcium-silicon ratio (the CaO in the lime milk and the SiO in the fly ash desilication semen 2 The ratio of the amount of substance) is 0.95 and mixed evenly, moved into the causticization tank, and stirred at a stirring rate of 150r·min -1 1. Carry out causticizing reaction at a reaction temperature of 110°C for 1 hour; move the slurry after the causticizing reaction into a filter for solid-liquid separation to obtain solid-phase calcium silicate slag and liquid-phase sodium hydroxide solution; process water and calcium silicate The slag is mixed evenly according to the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com