Integrated calcination method for dealkalization and magnetization of Bayer process red mud

A Bayer red mud and dealkalization technology, applied in the field of comprehensive utilization of solid waste, can solve the problems of high cost and difficult promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

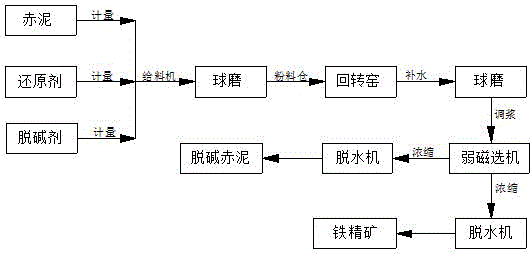

Method used

Image

Examples

Embodiment Construction

[0017] Red mud, lime, and coal powder are mixed according to the ratio of 100:15:25. After mixing evenly, they are roasted in a roasting furnace. After roasting at a furnace temperature of about 1200°C for 10 minutes, they are taken out and cooled rapidly under the action of cold water. After roasting, The material is crushed and ground to -200 mesh, more than 80%, and then separated by a magnetic separator under the condition of an induced magnetic field of 5500Gs. The results obtained are as follows:

[0018] Table 1. Iron element recovery form in red mud

[0019] Composition (wt%) Yield(%) Iron content (%) Recovery rate(%) Red mud raw material 100 18.09

Red mud after roasting and separation 13.81 72.80 55.58

[0020] Table 2. Element content composition of red mud before and after roasting

[0021] Composition (wt%) SiO 2 Al 2 o 3 Fe 2 o 3 CaO K 2 o Na 2 o P 2 o 5 Red mud raw material 21.6 21....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com