Method for producing cement clinker by utilizing red mud

A cement clinker and red mud technology, which is applied in cement production and other directions, can solve the problems of low red mud utilization rate and large energy consumption, and achieve the effects of reduced energy consumption, improved comprehensive utilization rate, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

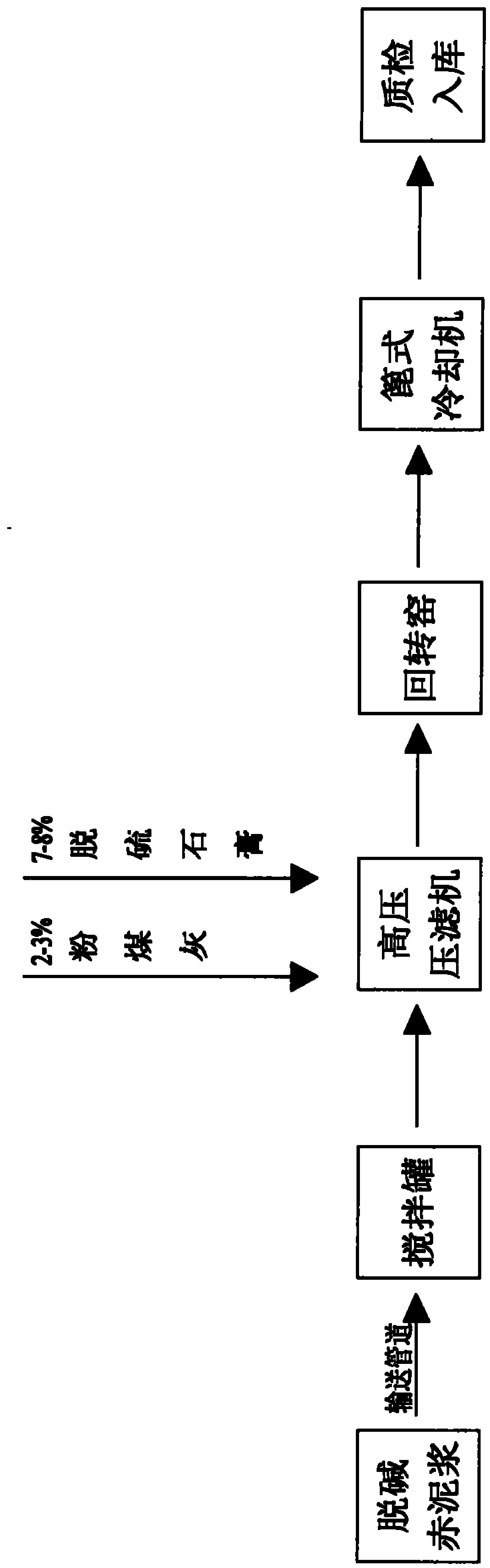

[0017] Embodiment: A kind of method of utilizing red mud to produce cement clinker, mainly comprises the following steps: the dealkalized red mud of alumina plant is sent into the mixing tank through discharge conveying pipeline, and the concentration of red mud is about 30% (in terms of solid content) , its temperature is about 85°C, and its Na2O content is below 1%; then add two kinds of auxiliary materials: one is 7-8% (relative to the mass ratio of red mud solid) dealkalized gypsum, and the other is 2-3% % (mass ratio relative to red mud solids) fly ash. After the above three materials are mixed evenly in the mixing tank, the concentration is adjusted to 30%, and the temperature is about 60°C, then sent to the plate and frame high-pressure filter press, and filtered under the pressure of 2.0Mpa to form a red with a water content of less than 25%. The clay product is then sent to a rotary kiln by a belt conveyor for high-temperature firing at a firing temperature of 1200-12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com