Preparation method of 3-mercaptopropyltriethoxysilane coupling agent

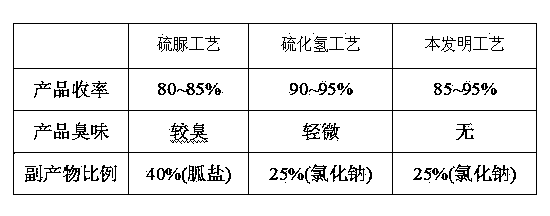

A mercaptopropyl triethoxy silane coupling agent, chloropropyl triethoxy silane technology, applied in the field of preparation of 3-mercaptopropyl triethoxy silane coupling agent, can solve guanidine salts and products Great odor, high production safety risk, large environmental pollution and other problems, to achieve the effect of small product odor, safe production process, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 3000ml four-neck flask, install a condenser, a mechanical stirrer, a thermometer and a water bath heating pot. Put 480 g of flaky sodium hydrosulfide solids with a mass content of 70% and 600 g of tap water into a flask, and stir at room temperature for 10 minutes to dissolve the sodium hydrosulfide to form a yellow transparent sodium hydrosulfide aqueous solution. Then heat up to 60~65°C, put 95g of sodium bicarbonate powder into the flask and stir for 5 minutes, after the sodium bicarbonate is dissolved, the pH of the reaction system is 9~10. Continue to heat up to 80~85°C, add 45g of benzyltributylammonium chloride as a phase transfer catalyst, add 1450g of 3-chloropropyltriethoxysilane dropwise at 80~85°C and stir for reaction, 3- The dropping time of chloropropyltriethoxysilane is about 2 hours. After the dropwise addition, the reaction was continued for 8 hours, and the crude product of the upper organic phase was detected by gas chromatography. At this time...

Embodiment 2

[0024] In a 3000ml four-neck flask, install a condenser, a mechanical stirrer, a thermometer and a water bath heating pot. Put 480g of sodium hydrosulfide with a mass content of 73% and 700g of tap water into the flask, stir at room temperature for 10 minutes, and dissolve the sodium hydrosulfide to form a yellow transparent sodium hydrosulfide aqueous solution. Then heat up to 70~75°C, drop 110g of sodium bicarbonate powder into the flask and stir for 5 minutes, after the sodium bicarbonate dissolves, the pH of the reaction system is 9~10; continue to heat up to 85~90°C, add 50g of benzyl tri Butyl ammonium chloride is used as a phase transfer catalyst, and 1450g of 3-chloropropyltriethoxysilane is added dropwise at 85~90°C and stirred for reaction, and the dropping time of 3-chloropropyltriethoxysilane is 2.5 hours or so. After the dropwise addition, the reaction was continued for 10 hours, and the crude product of the upper organic phase was detected by gas chromatography....

Embodiment 3

[0027] In a 3000ml four-neck flask, install a condenser, a mechanical stirrer, a thermometer and a water bath heating pot. Put 480 g of sodium hydrosulfide solid with a mass content of 73% and 800 g of tap water into the flask, and stir at room temperature for 10 minutes to dissolve the sodium hydrosulfide to form a yellow transparent sodium hydrosulfide aqueous solution. Then heat up to 80~85°C, put 120g of sodium bicarbonate powder into the flask and stir for 5 minutes, after the sodium bicarbonate dissolves, the pH of the reaction system is 9~10; after continuing to heat up to 88~90°C, add 50g of hexadecane Trimethylammonium chloride was used as a phase transfer catalyst, and 1450g of 3-chloropropyltriethoxysilane was added dropwise under the condition of 88~90℃ to stir the reaction, and the dropping time of 3-chloropropyltriethoxysilane for about 3 hours. After the dropwise addition, the reaction was continued for 12 hours, and the crude product of the upper organic phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com