Process for recovering hydrogen sulfide form anaerobic fermentation methane

An anaerobic fermentation, hydrogen sulfide technology, applied in hydrogen sulfide, gas fuel, petroleum industry and other directions, can solve problems such as high cost, operator injury, combustion equipment corrosion, etc., to improve environmental protection processes, reduce manufacturing costs, and reduce pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

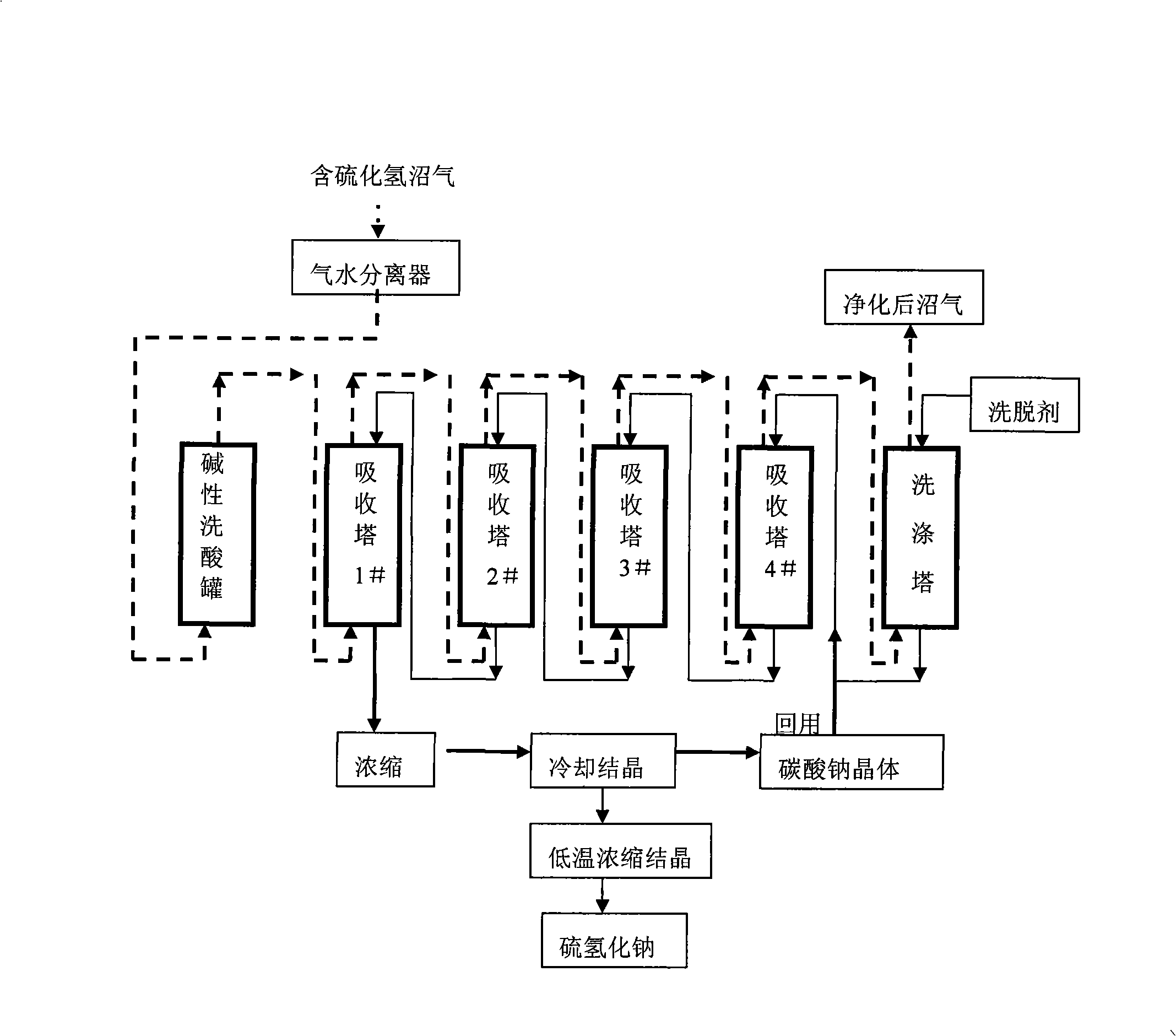

[0035] A sewage treatment plant with a biogas output of 1000m 3 / h, hydrogen sulfide content in biogas 5000mg / m 3 , The methane also contains 60% (v / v) of methane, 30-35% (v / v) of carbon dioxide, and 5% (v / v) of water.

[0036] 1. The biogas first passes through the gas-water separator, and then enters the 2m 3 The alkaline acid washing tank is equipped with 1% sodium hydroxide solution by weight fraction in the tank, and the gas residence time of each cubic meter of biogas in the tank is 10 seconds.

[0037] 2. There are two absorption towers ( ), each level of absorption tower is equipped with a stirring return tank. The biogas first enters the first-stage absorption tower (1# tower), and the biogas from the first-stage absorption tower enters the second-stage absorption tower (2# tower). When the pH value of the absorption liquid in the first-stage absorption tower (1# tower) is less than 9.0, the hydrogen sulfide concentration in the biogas is detected, and when the h...

Embodiment 2

[0045] A sewage treatment plant with a biogas output of 300m 3 / h, hydrogen sulfide content in biogas 2000mg / m 3 , The biogas also contains 50% (v / v) of methane, 40-45% (v / v) of carbon dioxide, and 5% (v / v) of water.

[0046] 1. The biogas first passes through the gas-water separator, and then enters 1m 3 The alkaline washing acid tank is equipped with 5% sodium carbonate solution, and the gas residence time of each cubic meter of biogas in the tank is 15 seconds.

[0047] 2. There are three-stage absorption towers ( ), each level of absorption tower is equipped with a stirring return tank. The biogas first enters the first-stage absorption tower (1# tower), the biogas from the first-stage absorption tower enters the second-stage absorption tower (2# tower), and the biogas from the second-stage absorption tower enters the third-stage absorption tower (3# Tower). When the pH value of the absorption liquid in the first-stage absorption tower (1# tower) is less than 9.0, th...

Embodiment 3

[0053] A sewage treatment plant with a biogas output of 500m 3 / h, the content of hydrogen sulfide in biogas is 4000mg / m 3 , The biogas also contains methane content of 45% (v / v), carbon dioxide content of 40-45% (v / v), and water content of 5% (v / v).

[0054] 1. The biogas first passes through the gas-water separator, and then enters 1m 3 Alkaline acid washing tank, the tank is filled with 1% potassium hydroxide solution.

[0055] 2. There are two-stage absorption towers ( ), each level of absorption tower is equipped with a stirring return tank. The biogas first enters the first-stage absorption tower (1# tower), the biogas from the first-stage absorption tower enters the second-stage absorption tower (2# tower), and the biogas from the second-stage absorption tower enters the third-stage absorption tower (3# Tower). When the pH value of the absorption liquid in the first-stage absorption tower (1# tower) is less than 9.0, the hydrogen sulfide concentration in the bioga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com