Application of polyporous material in sodium polysulfide/bromine accumulation energy power cell electric pole

A porous material, sodium polysulfide technology, applied in battery electrodes, regenerative fuel cells, electrode manufacturing, etc., can solve the problems of low redox reaction activity, reduce electrochemical polarization of electrode reactions, etc., to speed up the commercialization process, reduce Battery cost, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Cut the nickel foam into small pieces of 20×30×3.19mm as the negative electrode material of the battery, use polyacrylonitrile carbon felt (20×30×3.19mm) as the positive electrode material, and boil the positive electrode material in 1mol / l NaOH solution before use 40 minutes to make it hydrophilic.

[0052] The prepared electrode area is 600mm 2 , thickness 3.19mm.

[0053] Nafion-117 membrane is selected as the cation exchange membrane. Before use, the membrane needs to be heated in a 353K water bath with 1.0mol / l NaOH solution for about 2 hours, and then washed with deionized water for pretreatment to convert the hydrogen form of the membrane into sodium Type membrane, and remove organic and inorganic impurities in the membrane.

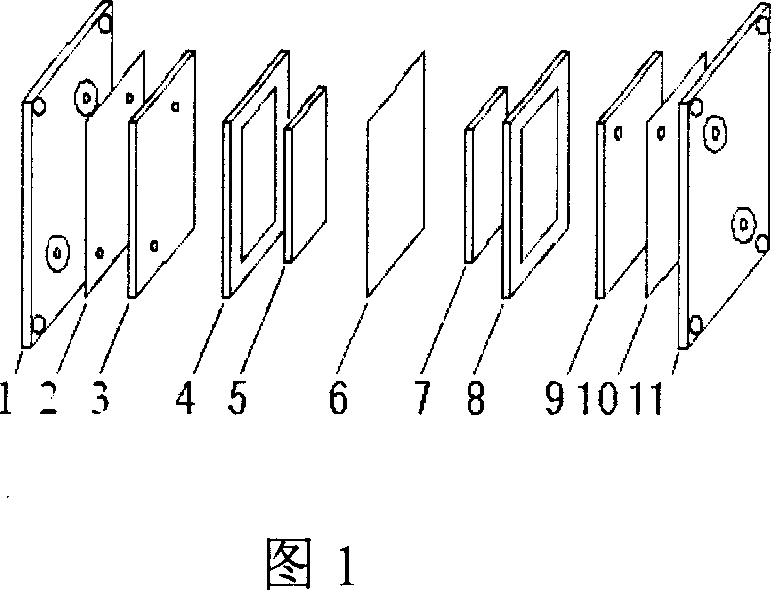

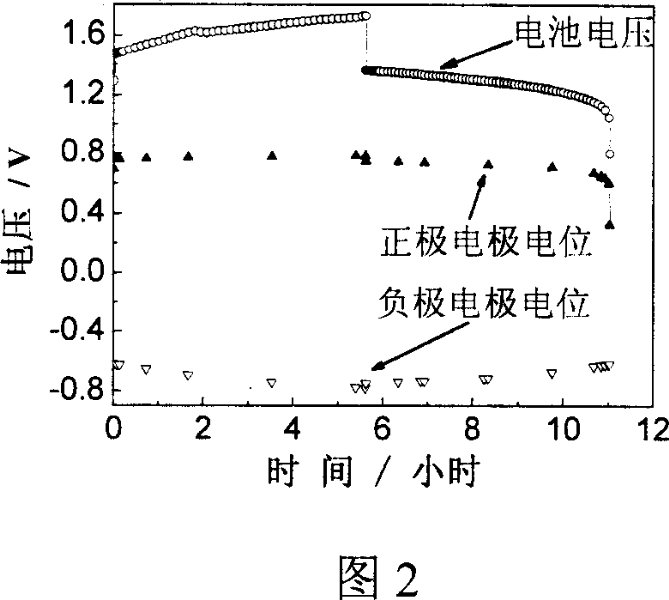

[0054] Assemble the battery according to Figure 1, and test the performance of the battery on a single-cell evaluation device. See Figure 2 for the relationship between voltage and time during battery and single-electrode constant curren...

Embodiment 2

[0058] The graphite felt and the carbon felt were cut into 20×30×3.19 mm in size, and boiled in 1 mol / l NaOH solution for 40 minutes before use to make them hydrophilic. Carbon felt is used as the positive electrode material of the battery, and the graphite felt of the negative electrode is subjected to chemical deposition of nickel on the surface. The process steps are as follows: polyacrylonitrile graphite felt→roughening→water washing→presoaking→activation→water washing→degelling→water washing→electroless plating→water washing.

[0059] Formula and operating conditions:

[0060] Coarsening: 50% HNO 3 Solution, room temperature, time: 10-20 minutes

[0061] Pre-dipping: stannous chloride: 30-50g / l, hydrochloric acid (36-38% by weight): 100ml / l, room temperature, time: 1-3 minutes

[0062] Activation: colloidal palladium activation solution, room temperature, time: 5-10 minutes

[0063] Degumming: industrial hydrochloric acid (36-38%): 100ml / l, temperature: 45°C, time: 3-5...

Embodiment 3

[0072] Change negative electrode graphite felt into carbon felt in embodiment 2, and its processing method is unchanged.

[0073] Select Nafion-117 membrane as the cation exchange membrane, and its treatment method is the same as that in Example 1.

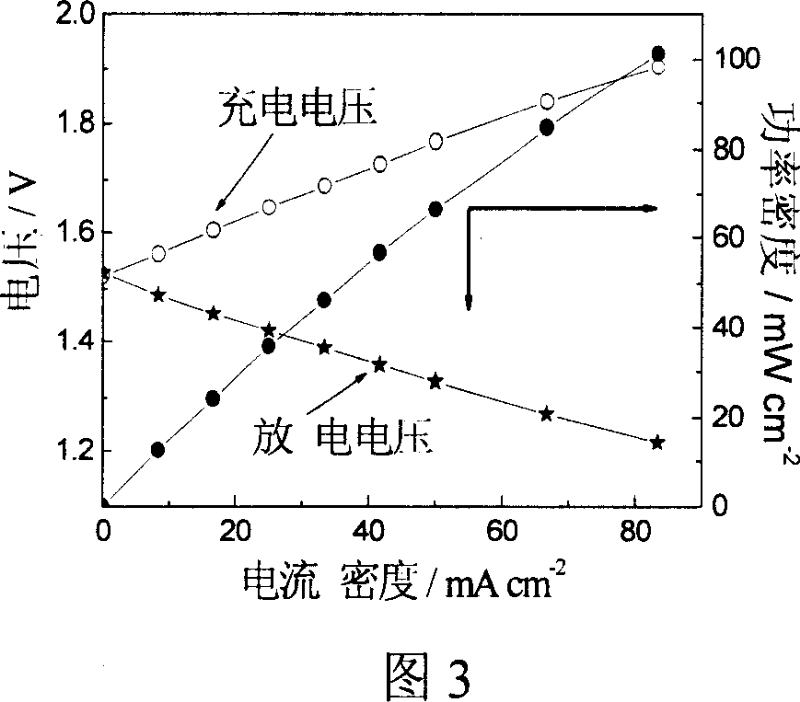

[0074] A battery was assembled according to Figure 1, and the performance of the battery was tested on a single-cell evaluation device, and the operating conditions were the same as in Example 1. The initial negative electrode electrolyte is 1.3mol / l Na 2 S 4 Solution 50ml, positive electrode electrolyte is 4.0mol / l NaBr solution 50ml, at constant flow 0.04A / cm 2 After charging for 5.58 hours, the polarization curve and energy density curve during charging and discharging of the battery are shown in Figure 5. It can be seen from the figure that when the battery is at 0.04A / cm 2 When working under high conditions, the energy density of the battery is 53.96mW / cm 2 , while 0.05A / cm 2 The energy density reaches 65.4mW / cm at the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com