Method for preparing porous carbon radical electrode of sodium polysulfate / bromine energy storage cell

An energy storage battery, sodium polysulfate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of electrode performance and stability, slow electrochemical reaction rate, high resistance of granular activated carbon, etc., to achieve high electrode performance , multi-electrochemical reaction interface, porosity controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

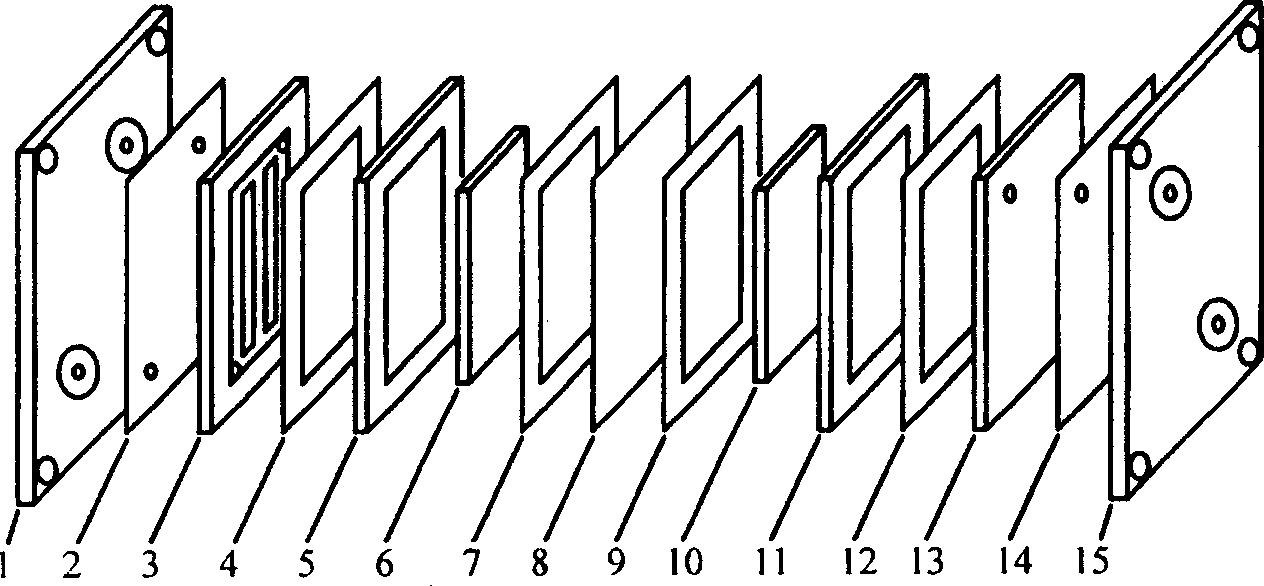

[0048] Mix XC-72 carbon (U.S. Cabot Corp., the same below), activated carbon particles (Shanxi Xinhua Chemical Factory, the same below) and polyvinylidene fluoride (Shanghai Sanaifu New Material Co., Ltd., the same below) powder in a certain weight ratio , activated carbon particle diameter 0.20-0.45mm, specific surface area 830m 2 / g, weight ratio XC-72 carbon: activated carbon particles: polyvinylidene fluoride=15: 70: 15, the mixed powder is placed in the mould, hot-pressed forming, hot-pressing temperature 200 ℃, the pressure of hot-pressing is controlled at 2Mpa The hot pressing time is 30min. After the electrode was naturally cooled, the electrode was impregnated with 20% ethanol aqueous solution, then impregnated with 1.0mol / l NaOH aqueous solution at a temperature of 80°C, and finally washed with 80°C deionized water until the pore-forming agent was removed.

[0049] The prepared electrode area is 5cm 2 , electrode thickness and bulk resistance are shown in Table 1. ...

Embodiment 1b

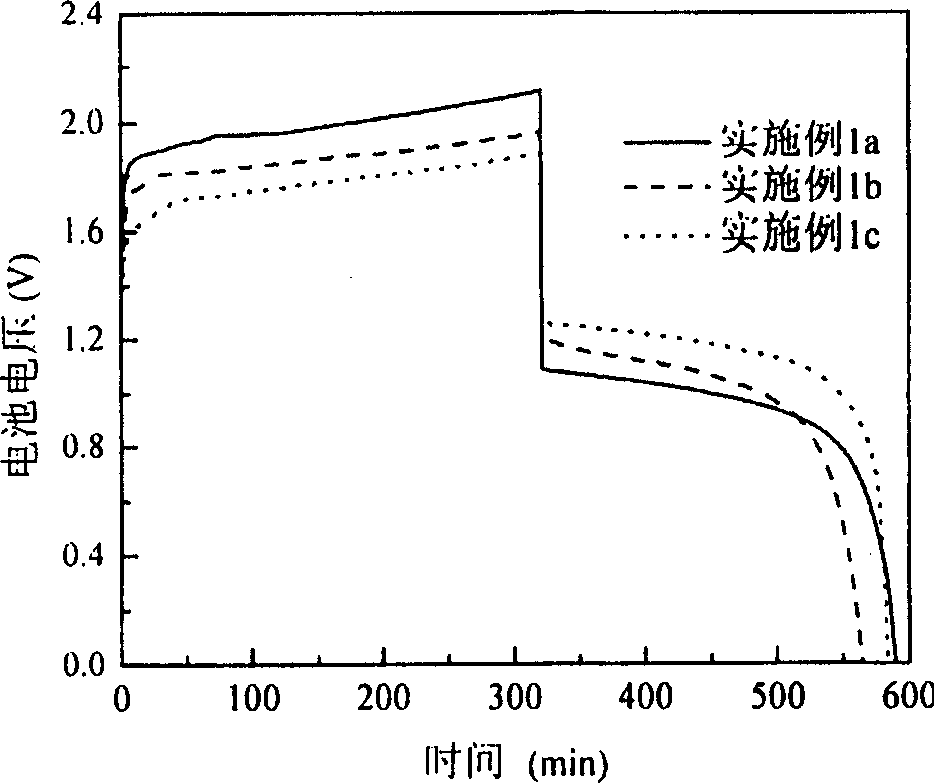

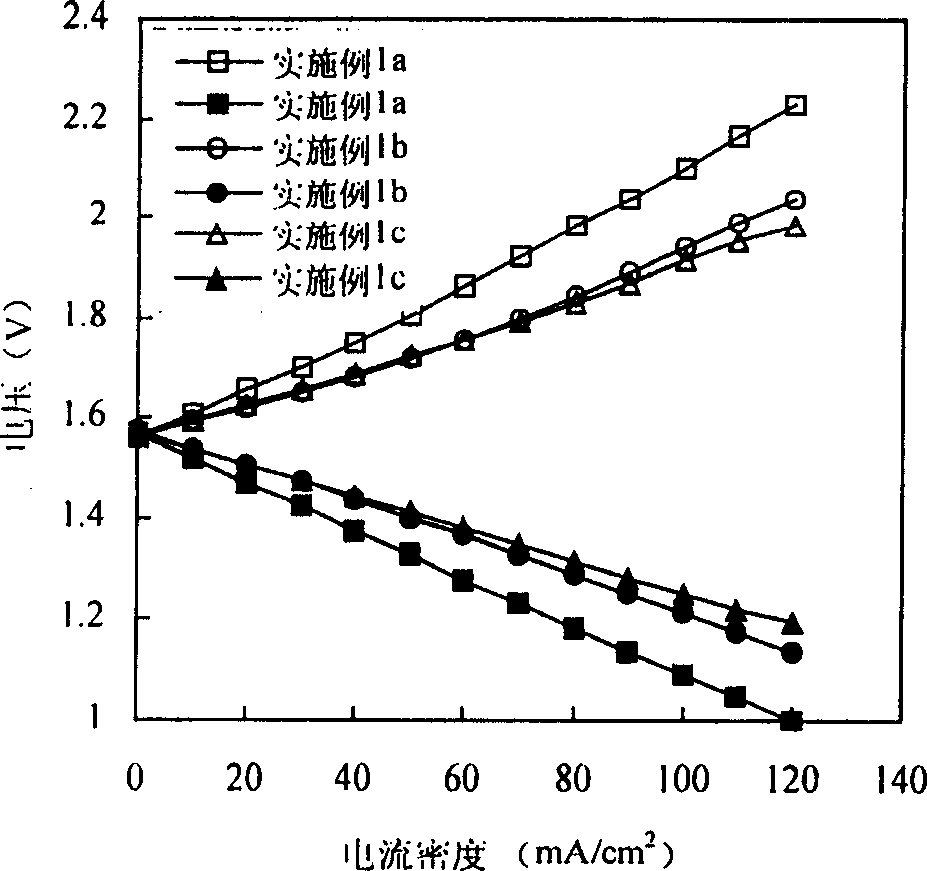

[0054] Weight ratio XC-72 carbon: activated carbon particles: polyvinylidene fluoride = 15:70:15, and then add a certain amount of sodium chloride pore-forming agent, weight ratio sodium chloride: XC-72 carbon + activated carbon particles + polyvinylidene fluoride The ratio of vinylidene fluoride is 20:80, and the diameter of activated carbon particles is 0.20-0.45mm. Prepare electrodes and assemble batteries according to the electrode preparation method of Example 1a, and the operating conditions are the same as in Example 1a. figure 2 , the polarization curves of the battery during charging and discharging are shown in image 3 , the thickness and volume resistance of the electrodes are shown in Table 1.

Embodiment 1c

[0056] Weight ratio XC-72 carbon: activated carbon particles: polyvinylidene fluoride = 15:70:15, and then add a certain amount of sodium chloride pore-forming agent, weight ratio sodium chloride: XC-72 carbon + activated carbon particles + polyvinylidene fluoride The ratio of vinylidene fluoride is 30:70, and the diameter of activated carbon particles is 0.20-0.45mm. Prepare electrodes and assemble batteries according to the electrode preparation method of Example 1a, and the operating conditions are the same as in Example 1a. figure 2 , the polarization curves of the battery during charging and discharging are shown in image 3 , the thickness and volume resistance of the electrodes are shown in Table 1.

[0057] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com