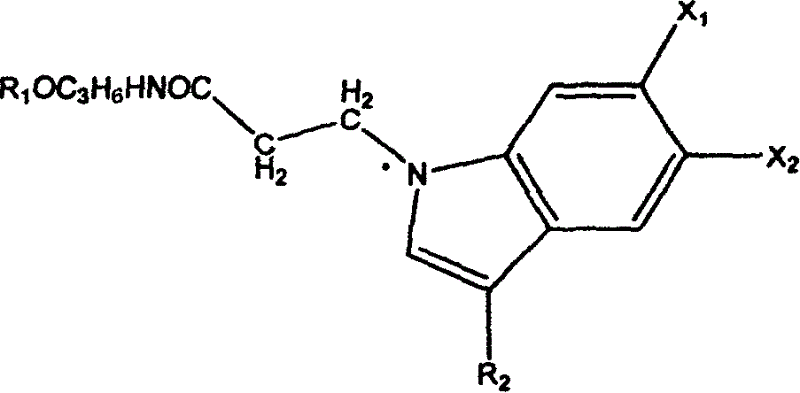

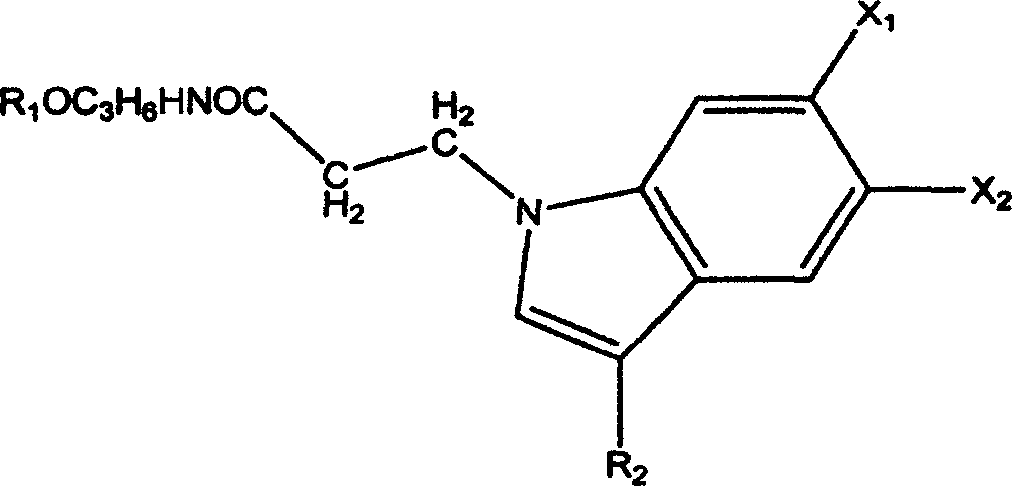

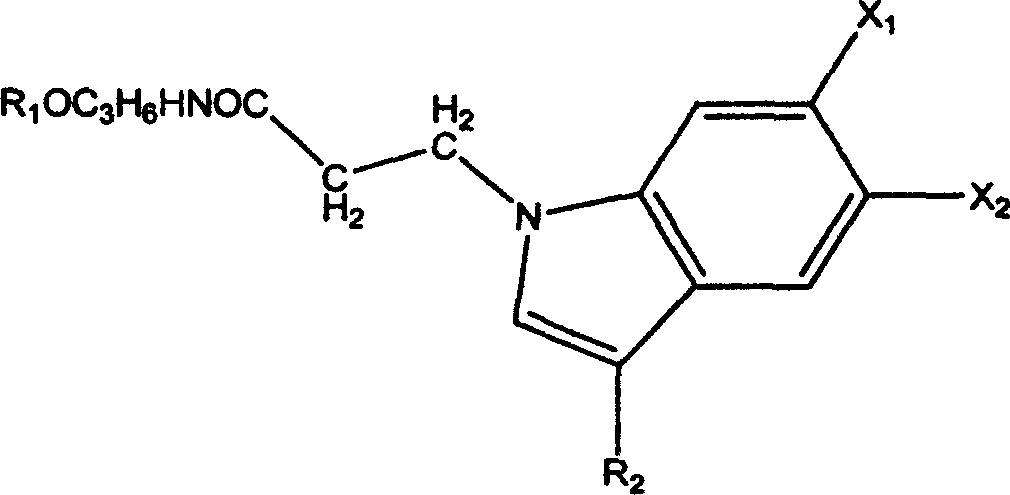

Amide derivative of indole, its preparation method and application

A technology of amide derivatives and indole, which is applied in the field of indole derivatives, can solve problems such as environmental pollution, toxicity, and impact on human health, and achieve high-efficiency antifouling activity and significant bactericidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] 1. Preparation of dimethyl β-dithiodipropionate

[0011] Add 45.0g (0.19mol) Na to a 250ml beaker 2 S.9H 2 0 and 8.8g (0.28mol) of sulfur powder, heated to boiling until completely dissolved, and filtered with suction after cooling to obtain a red clear sodium polysulfide solution, cooled to -5~10°C for later use.

[0012] Add 200g of 10% (weight percent concentration, the same below) NaHCO successively in a 500ml three-necked flask equipped with a stirring device, a condenser, and a thermometer. 3 Aqueous solution, 21.7g (0.25mol) of methyl acrylate, cooled to -5 ~ 10 ℃ and maintained at this temperature, dropwise added the above aqueous solution of sodium polysulfide within 2 hours. After dropping, the reaction was continued for 6 h at room temperature, and the reaction ended. Leave to stand for stratification, add 120g of 1mol / L Na to the oil layer after removing the water layer 2 SO 3 aqueous solution, and then continue to react at 50°C for 3h, and the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com