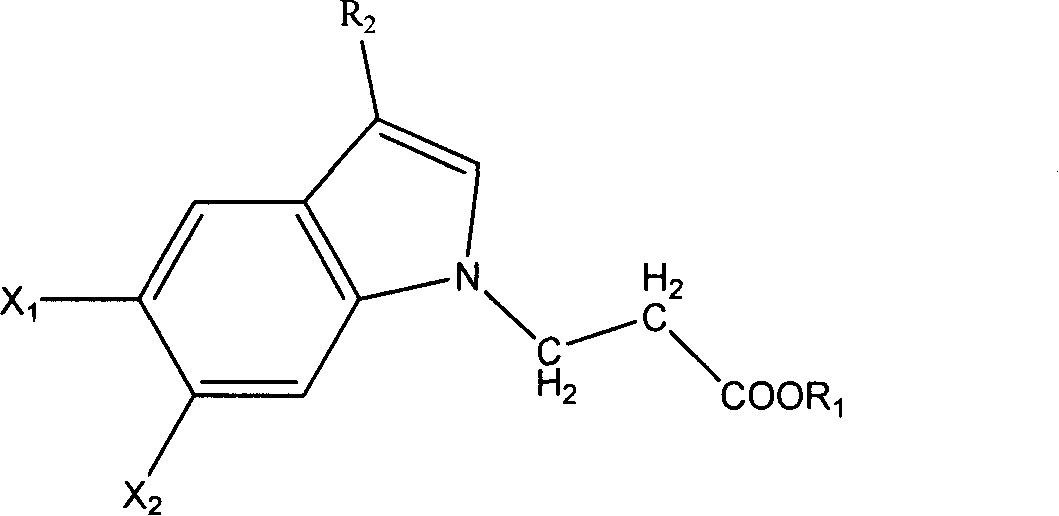

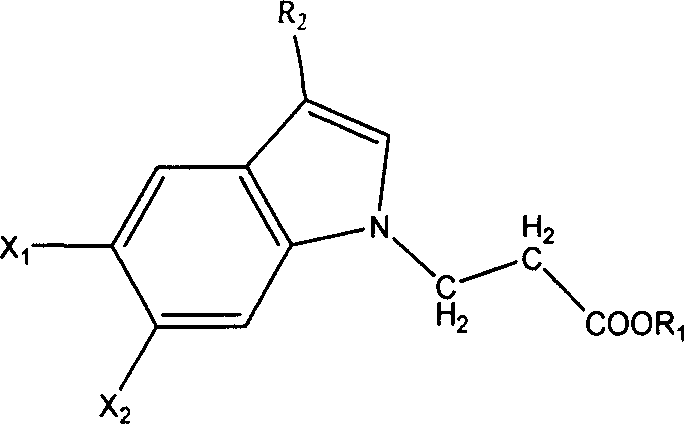

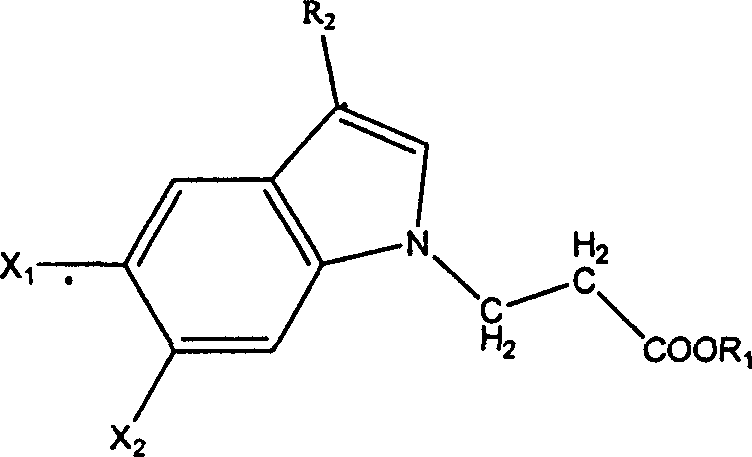

Ester derivative of indole, its preparation method and application

A derivative, indole technology, applied in the field of indole derivatives, can solve problems such as toxicity, environmental pollution, and human health, and achieve high-efficiency antifouling activity and important bactericidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] 1. Preparation of dimethyl β-dithiodipropionate

[0011] Add 45.0g (0.19mol) Na to a 250ml beaker 2 S.9H 2 0 and 8.8g (0.28mol) of sulfur powder, heated to boiling until completely dissolved, cooled and filtered with suction to obtain a red clear sodium polysulfide solution, cooled to -5 to 10°C for later use.

[0012] Add 200g of 10% (weight percent concentration, the same below) NaHCO successively in a 500ml three-necked flask equipped with a stirring device, a condenser, and a thermometer. 3 Aqueous solution, 21.7g (0.25mol) of methyl acrylate, cooled to -5 ~ 10 ℃ and maintained at this temperature, dropwise added the above aqueous solution of sodium polysulfide within 2 hours. After dropping, the reaction was continued for 6 h at room temperature, and the reaction ended. Leave to stand for stratification, add 120g of 1mol / L Na to the oil layer after removing the water layer 2 SO 3 aqueous solution, and then continue to react at 50°C for 3h, and the reaction end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com