Composite nanomaterials, their preparation methods and applications

A technology of composite nanomaterials and coatings, applied in the field of its preparation and composite nanomaterials, can solve the problems of marine environmental pollution, economic loss, easy enrichment of antifouling agents, etc., and achieve broad application prospects, spectral antifouling activity, antifouling outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

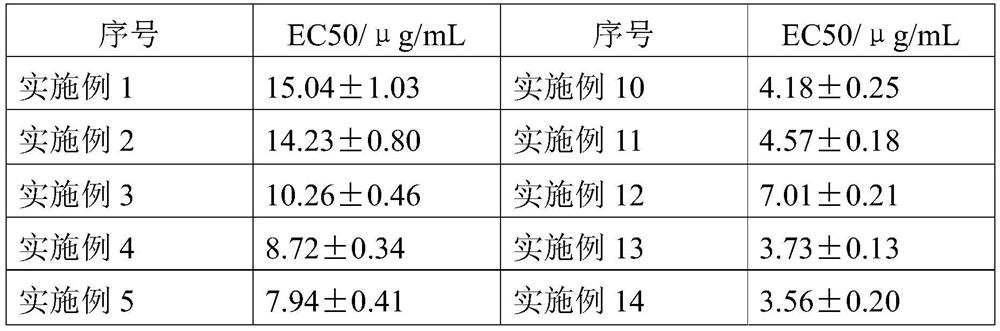

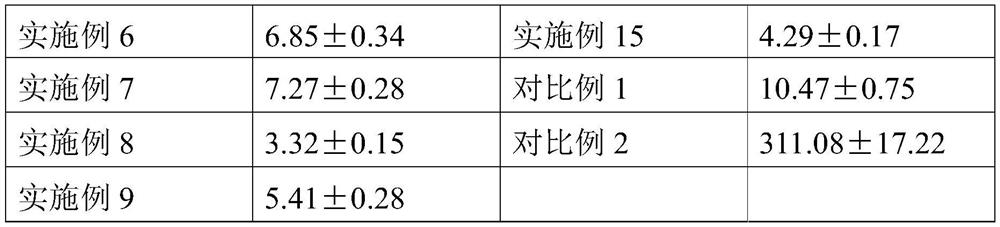

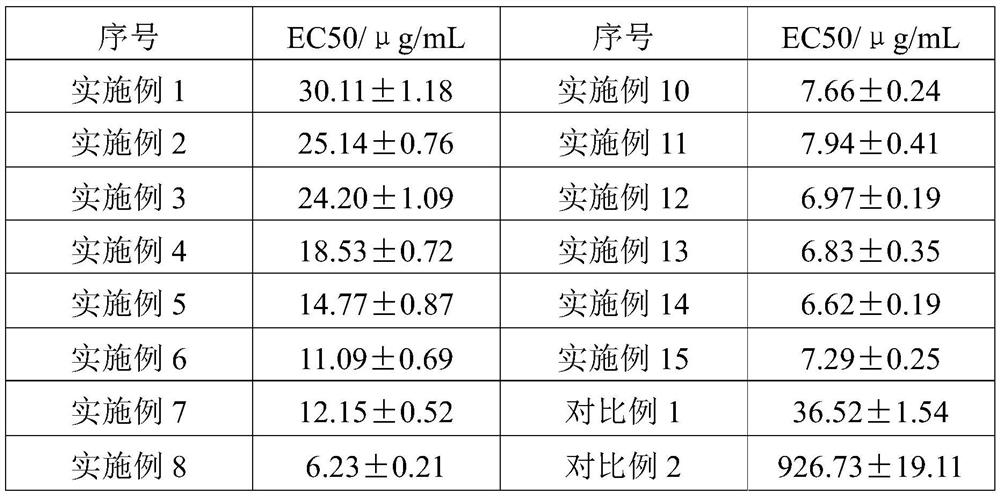

Examples

preparation example Construction

[0019] The preparation method of the composite nanomaterial of the specific embodiment of the present invention comprises: S1, precursor MnO@CoO@TiO 2 preparation; S2, doping with transition elements to obtain a composite nanomaterial intermediate doped with transition metal elements; S3, doping with rare earth elements. The order of steps S2 and S3 is not particularly limited, and the transition element doping may be performed first, followed by the rare earth element doping, or the transition element and the rare earth element may be doped together.

[0020] Specifically, the precursor MnO@CoO@TiO 2 The preparation includes: weighing manganese salt and cobalt salt in proportion, preparing solution A, the concentration of manganese salt in solution A is 0.05mol / L~1.0mol / L, and the concentration of cobalt salt is 0.05mol / L~1.0mol / L , the manganese salt can be manganese nitrate, manganese dichloride, etc.; the cobalt salt can be cobalt nitrate or cobalt dichloride, etc.; under...

Embodiment 1

[0028] The preparative reaction was carried out on the basis of the molar ratio n(Mn):n(Co):n(Ti)=1:1:1. First, take manganese nitrate and cobalt nitrate in proportion to prepare solution A, in which Mn(NO 3 ) 2 The concentration is 0.05mol / L, Co(NO 3 ) 2 The concentration is 0.05mol / L; then, under stirring, titanium tetrachloride and NaOH solution with a concentration of 0.05mol / L are slowly dropped into liquid A, and the stirring reaction is continued for 2 hours to obtain a uniform transparent sol, filter the precipitate, and use Wash 3 times with deionized water; finally, dry the obtained precipitate in a vacuum drying oven at 60°C, then place it in a crucible, calcinate at 600°C for 4 hours in a reducing atmosphere, and cool naturally to room temperature to obtain the precursor MnO@CoO@TiO 2 .

Embodiment 2

[0030] The preparation reaction was carried out on the basis of the molar ratio n(Mn):n(Co):n(Ti)=15:9:100. First, take manganese nitrate and cobalt nitrate in proportion to prepare solution A, in which Mn(NO 3 ) 2 The concentration is 1mol / L, Co(NO 3 ) 2 The concentration is 1 mol / L; then, under stirring, slowly drop titanium tetrachloride and NaOH solution with a concentration of 2 mol / L into liquid A, and continue stirring for 6 hours to obtain a uniform transparent sol, filter the precipitate, and use deionized Washed with water for 3 times; finally, the obtained precipitate was dried in a vacuum drying oven at 100°C, then placed in a crucible, calcined at 1000°C for 12 hours in a reducing atmosphere, and cooled naturally to room temperature to obtain the precursor MnO@ CoO@TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com