Method for extracting and separating nickel, cobalt and magnesium from nickel, cobalt and magnesium mixed solution

A mixed solution, nickel-cobalt-magnesium technology, applied in the field of extraction and separation of nickel, cobalt and magnesium from nickel-cobalt-magnesium mixed solution, can solve the problem that the impurity content is difficult to meet the raw material requirements of battery materials, the separation of nickel and magnesium is incomplete, and the separation of cobalt and magnesium Incomplete and other problems, to achieve the effect of low cost, good quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

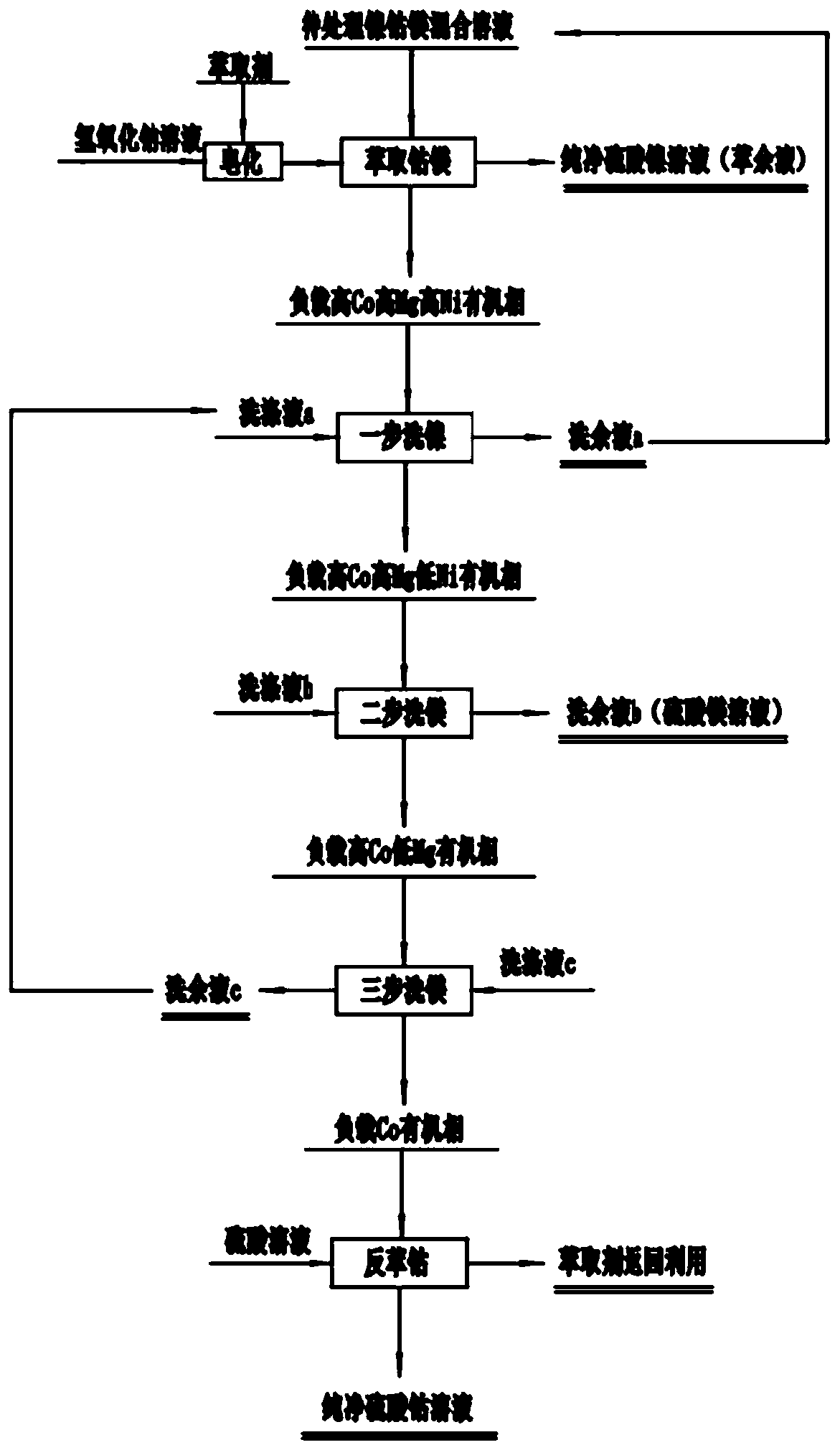

Method used

Image

Examples

Embodiment 1

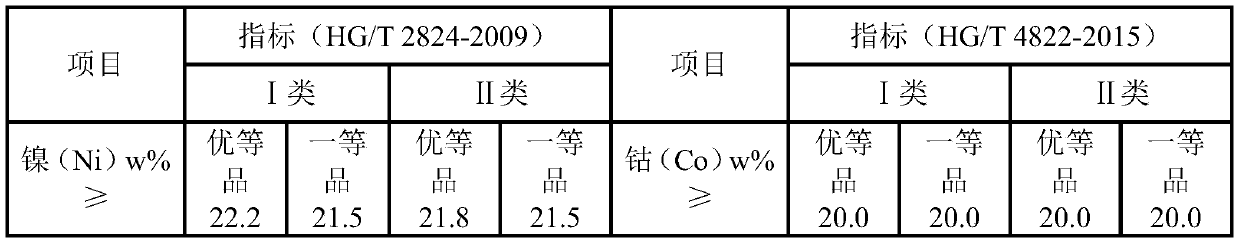

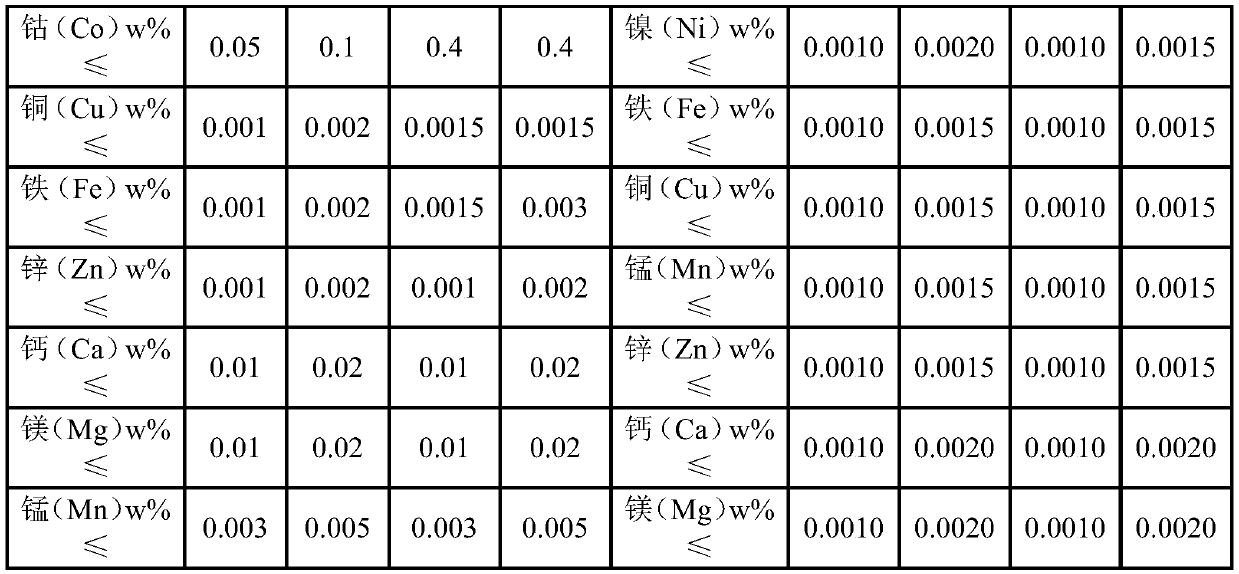

[0055] The nickel-cobalt-magnesium mixed solution to be treated used in the present embodiment, the chemical composition analysis results are shown in Table 1:

[0056] Table 1 Chemical composition of nickel-cobalt-magnesium mixed solution to be treated (g / L)

[0057] element Ni co Mg Ca Fe Cu Zn Al content 68.08 5.81 3.25 <0.001 <0.001 <0.001 <0.001 <0.001

[0058] It can be seen from the data in Table 1 that the content of other impurities in the nickel-cobalt-magnesium mixed solution can meet the requirements, and only need to separate the three elements of nickel, cobalt, and magnesium from each other to obtain nickel sulfate products and cobalt sulfate products for battery materials respectively. ;

[0059] (1) P507 extraction of cobalt and magnesium: take 1000mL of the above-mentioned nickel-cobalt-magnesium mixed solution, add saponified P507 extractant, the volume fraction of P507 is 25%, the saponification rate is 30%, the co...

Embodiment 2

[0075] The mixed solution of nickel-cobalt-magnesium to be treated used in the present embodiment, the chemical composition analysis results are shown in Table 5:

[0076] Table 5 Chemical composition of nickel-cobalt-magnesium mixed solution to be treated (g / L)

[0077] element Ni co Mg Ca Fe Cu Zn Al content 85.69 7.54 4.25 <0.001 <0.001 <0.001 <0.001 <0.001

[0078] (1) P507 extracts cobalt-magnesium: get above-mentioned nickel-cobalt-magnesium mixed solution 1000mL, add saponification P507 extraction agent in the solution, P507 volume fraction is 20%, saponification rate is 35%, control compares O / A to be 1:2, Carry out 4 stages of counter-current extraction, then stand and separate to obtain the organic phase and raffinate with high Co, Mg and high Ni loads, the raffinate is pure nickel sulfate solution, its volume is 1000mL, and the concentrations of Co and Mg are respectively 0.05g / L and 0.06g / L, the chemical composition of pu...

Embodiment 3

[0089] The mixed solution of nickel-cobalt-magnesium to be treated used in the present embodiment, the chemical composition analysis results are shown in Table 8:

[0090] Table 8 Chemical composition of mixed solution of nickel-cobalt-magnesium to be treated (g / L)

[0091] element Ni co Mg Ca Fe Cu Zn Al content 95.47 15.21 10.38 <0.001 <0.001 <0.001 <0.001 <0.001

[0092] (1) P507 extracts cobalt-magnesium: get above-mentioned nickel-cobalt-magnesium mixed solution 1000mL, add saponification P507 extraction agent in the solution, P507 volume fraction is 30%, saponification rate is 20%, control compares O / A to be 2:5, Carry out 5 stages of countercurrent extraction, then stand and separate to obtain the organic phase and raffinate with high Co, Mg and high Ni load, the raffinate is pure nickel sulfate solution, its volume is 1000mL, and the concentrations of Co and Mg are respectively 0.07g / L and 0.07g / L, the chemical composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com