Cobalt-tungsten nanometer alloy plating layer and preparation method thereof

A nano-alloy, tungsten alloy technology, applied in nano-technology, nano-technology, nano-technology for materials and surface science, etc., to achieve the effect of energy saving, small investment and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

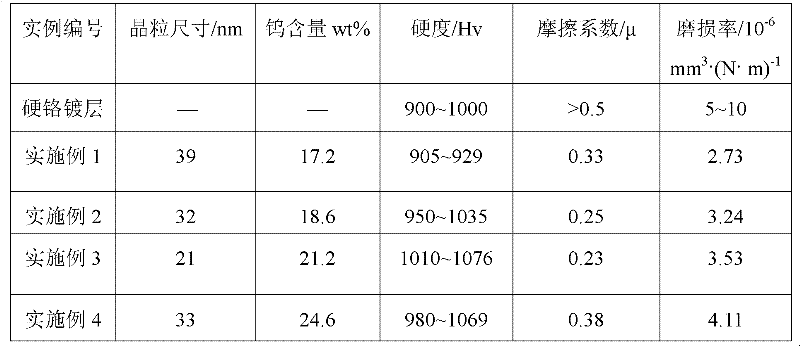

Embodiment 1

[0019] A preparation method of a cobalt-tungsten nano-alloy coating, the specific steps are as follows:

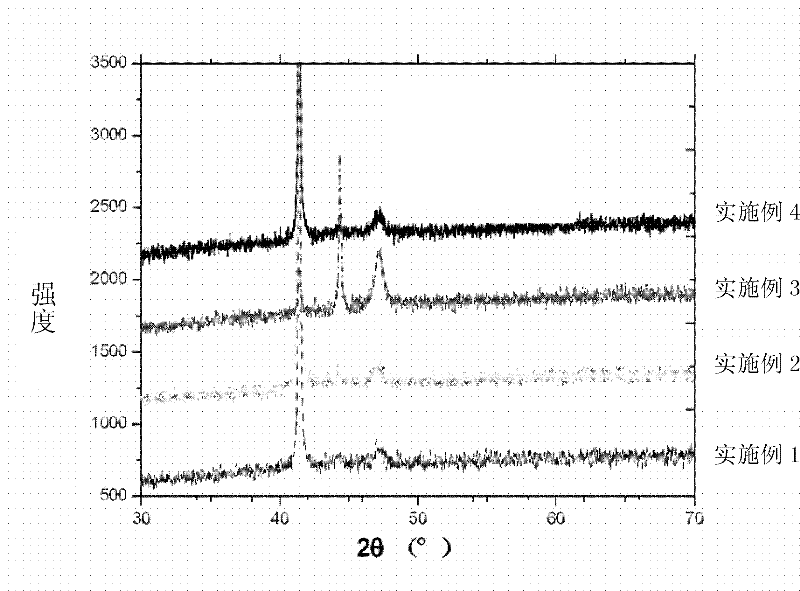

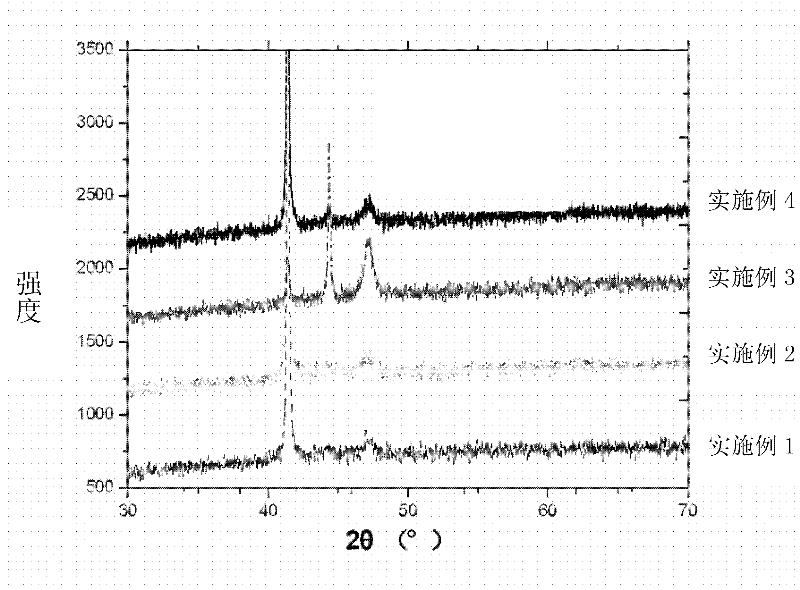

[0020] Prepare the electroplating solution of cobalt-tungsten nano-alloy coating, its component is to include in every liter of plating solution: 112g cobalt sulfate, 33g sodium tungstate, 19g boric acid, 0.06g sodium dodecylbenzenesulfonate, 59g sodium citrate, 100g sodium sulfate, 1g sodium saccharin. The above plating solution is electroplated, the anode is a platinum titanium mesh, and the cathode is a brass substrate that has undergone degreasing-cleaning-acid activation. Electroplating adopts double-pulse electroplating method, and the average current density of forward and reverse is 4A / dm respectively 2 and 0.4A / dm 2 , the forward and reverse pulse frequency is 1000hz, the magnetic stirring speed is 100 rpm, the control temperature is 20°C, the Ph value is 3, and the electroplating is 1h. The cobalt-tungsten nano-alloy coating is prepared, and its XRD spectrum is...

Embodiment 2

[0022] A preparation method of a cobalt-tungsten nano-alloy coating, the specific steps are as follows:

[0023] Prepare the electroplating solution of cobalt-tungsten nano-alloy coating, its component is to include in every liter of plating solution: 100g cobalt sulfate, 30g sodium tungstate, 20g boric acid, 0.05g sodium dodecylbenzenesulfonate, 60g sodium citrate, 100g sodium sulfate, 1.5g sodium saccharin. The above plating solution is electroplated, the anode is a platinum titanium mesh, and the cathode is a brass substrate that has undergone degreasing-cleaning-acid activation. Electroplating adopts double-pulse electroplating method, and the average current density of forward and reverse is 6A / dm respectively 2 and 0.6A / dm 2 , the forward and reverse pulse frequency is 800hz, the magnetic stirring speed is 100 rpm, the control temperature is 70°C, the Ph value is 8, and the electroplating is 3h, and the cobalt-tungsten nano-alloy coating is prepared, and its XRD spectr...

Embodiment 3

[0025] A preparation method of a cobalt-tungsten nano-alloy coating, the specific steps are as follows:

[0026] Prepare the electroplating solution of cobalt-tungsten nano-alloy coating, its component is to comprise in every liter of plating solution: 120g cobalt sulfate, 33g sodium tungstate, 30g boric acid, 0.06g sodium dodecylbenzenesulfonate, 59g sodium citrate, 100g sodium sulfate, 1g sodium saccharin. The above plating solution is electroplated, the anode is a platinum titanium mesh, and the cathode is a brass substrate that has undergone degreasing-cleaning-acid activation. Electroplating adopts double-pulse electroplating method, and the average current density of forward and reverse is 8A / dm respectively 2 and 0.8A / dm 2 , the forward and reverse pulse frequency is 1500hz, the magnetic stirring speed is 200 rpm, the control temperature is 50°C, the Ph value is 5, and the electroplating is 2h. The cobalt-tungsten nano-alloy coating is prepared, and its XRD spectrum i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com