Production method of electronic-grade cobaltous sulfate solution

A technology of cobalt sulfate solution and production method, which is applied in the chemical industry and can solve problems such as leakage of hazardous chemicals, long process flow, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The production of electronic-grade cobalt sulfate solution is carried out using crude cobalt hydroxide as raw material, which contains Co 27.86%, Ni0.15%, Cu 0.71%, Ca 1.48%, Fe 1.54%, Mn 5.02%, Mg 3.62%, water Shares 2.87%. The production steps are as follows:

[0026] A. Add crude cobalt hydroxide raw materials to cobalt-containing waste water for slurrying. The liquid-solid ratio of slurrying is 3:1. After slurrying, the liquid is dissolved with sulfuric acid and sodium sulfite, and the pH at the end point is controlled to be 1. After reacting for 1.5 hours, filter. The filtrate contains 42.36g / l of cobalt, and the total metal ion concentration is 80.12g / l. Put the filtrate into the iron removal kettle and add an oxidizing agent to carry out the iron removal reaction. At the same time, add soda ash to adjust the pH value, maintain the end point pH=3.1, and obtain After iron removal liquid and iron removal tailings, the iron removal tailings are paid separately;

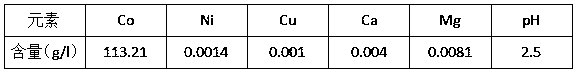

[...

Embodiment 2

[0033] The production of electronic-grade cobalt sulfate solution is carried out using crude cobalt hydroxide as raw material, which contains Co 23.07%, Ni0.16%, Cu 0.42%, Ca 1.13%, Fe 0.61%, Mn 4.78%, Mg 3.88%, water 33.54% share. The production steps are as follows:

[0034] A. Slurry raw cobalt hydroxide raw materials with new cobalt-containing water. The liquid-solid ratio of slurry is 4.5:1. After slurrying, the solution is dissolved with sulfuric acid and sodium sulfite, and the pH at the end point is controlled to be 1.6. After 1.5 hours of reaction, filter , the filtrate contains cobalt 36.72g / l, and the total metal ion concentration is 69.93g / l. Put the filtrate into the iron removal kettle and add an oxidant to carry out the iron removal reaction. Obtain iron-removing liquid and iron-removing tailings, and pay for iron-removing tailings;

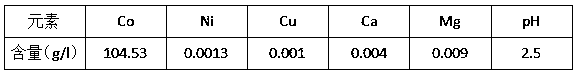

[0035] B, P204 organic extractant and sulfonated kerosene are mixed and prepared in a mass ratio of 3.5:1, and the above mixed ...

Embodiment 3

[0041] The production of electronic-grade cobalt sulfate solution is carried out using crude cobalt hydroxide as raw material, which contains Co 34.46%, Ni0.48%, Cu 2.47%, Ca 1.15%, Fe 1.22%, Mn 5.45%, Mg 5.81%, water 13.51%. The production steps are as follows:

[0042] A. Slurry raw cobalt hydroxide raw materials with cobalt-containing new water. The liquid-solid ratio of the slurry is 6:1. After slurrying, the liquid is dissolved with sulfuric acid and sodium sulfite, and the pH at the end point is controlled to be 2. After reacting for 1.5 hours, filter , the filtrate contains 53.2g / l of cobalt, and the total metal ion concentration is 77.51g / l. Put the filtrate into the iron removal kettle and add an oxidant to carry out the iron removal reaction. Obtain iron-removing liquid and iron-removing tailings, and pay for iron-removing tailings;

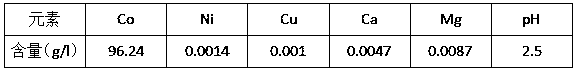

[0043] B, P204 organic extractant and sulfonated kerosene are mixed and prepared in a mass ratio of 4:1, and the above-mentioned mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com