Method for producing nickel sulfate and cobaltous sulfate through purification of laterite nickel ore sulfuric acid leaching solution and silica gel chelate resin

A technology of laterite nickel ore and chelating resin is applied in the field of laterite nickel ore leaching solution and silica gel chelating resin to produce nickel cobalt sulfate, and laterite nickel ore to produce nickel cobalt, which can solve the problem of environmental pollution, high cost, non-circulating organic acid, etc. problems, to achieve the effect of saving the use of acid, high nickel and cobalt extraction efficiency, and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

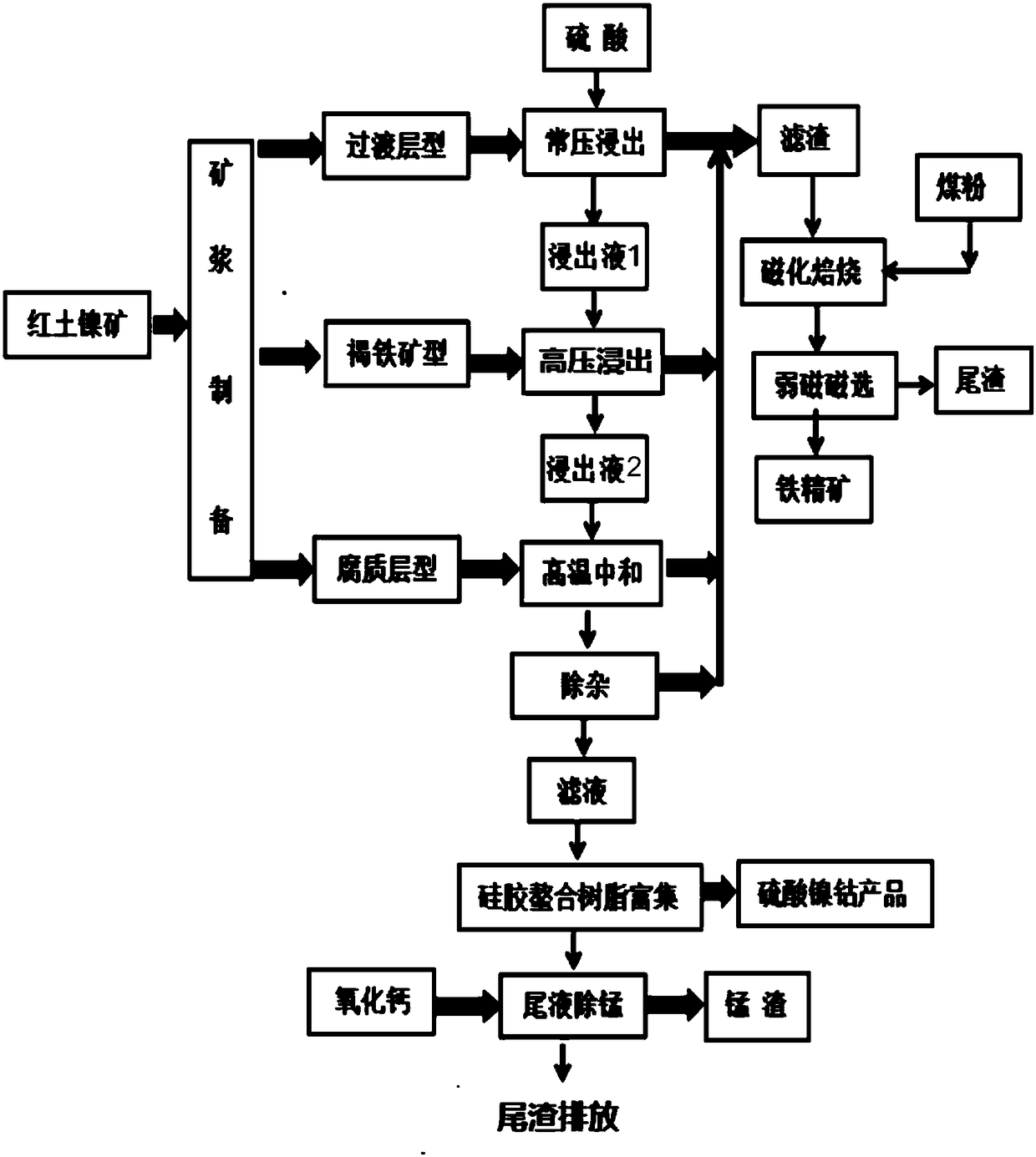

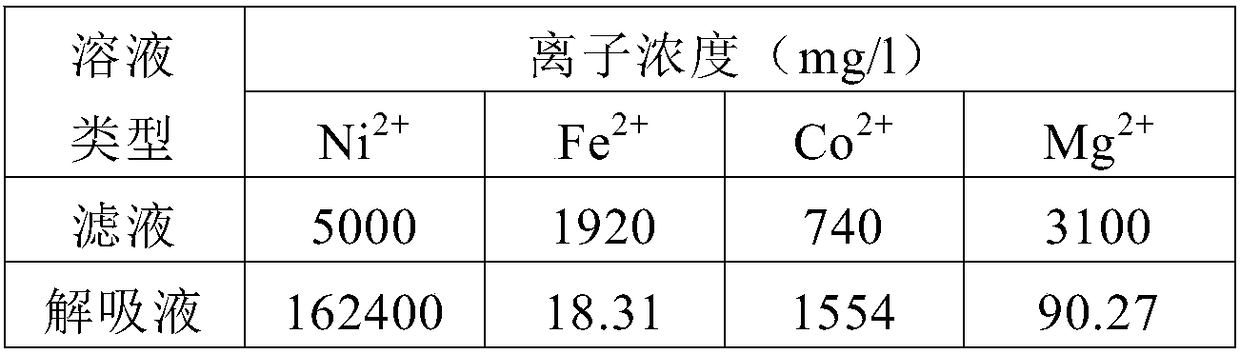

[0060] as figure 1 The shown process extracts nickel sulfate and cobalt sulfate, and the specific process is as follows:

[0061] The specific composition of the laterite nickel ore sample used is shown in Table 1:

[0062] Table 1 Type laterite nickel ore sample composition (%)

[0063] Ni

co

Fe

SiO 2

MgO

0.97

0.15

48.1

4.88

1.26

[0064] The dried limonite-type laterite-nickel ore, transition layer-type laterite-nickel ore, and humus-type laterite-nickel ore are respectively ground to -0.15mm ore powder accounting for more than 95%.

[0065] Add sulfuric acid and water to the transition layer type laterite nickel ore powder according to the sulfuric acid addition amount of 900kg / t ore and the liquid-solid ratio of 4:1, and carry out normal pressure leaching. The leaching temperature is 80°C, the leaching time is 2.5h, and then cooled to room temperature , solid-liquid separation to extract leachate 1 and filter residue 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com