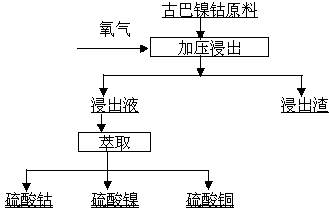

Method for leaching Cuba nickel-cobalt raw material

A leaching and nickel-cobalt technology, which is applied in the field of leaching Cuban nickel-cobalt raw materials, can solve the problems of environmental pollution, low leaching rate and large amount, and achieve the effect of reducing production cost and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Slurry 200g of Cuban nickel-cobalt raw material with 1 liter of aqueous solution added with 10ml of sulfuric acid and pour it into a 2L titanium-lined stainless steel autoclave, carry out oxidation leaching at a temperature of 130°C and a pressure of 0.5Mpa, react for 2 hours and then filter to obtain an oxidation leaching solution. Nickel, cobalt and copper are efficiently leached.

[0016] Operation results: the slag rate is 1.2%, and the acidity of the solution after the reaction is 0.31mol / L.

[0017] Reaction result: The leaching rate of copper is 99.21%, the leaching rate of cobalt is 99.9%, and the leaching rate of nickel is 99.9%.

Embodiment 2

[0019] Slurry 200g of Cuban nickel-cobalt raw material with 1.2 liters of aqueous solution adding 15ml of sulfuric acid and add it to a 2L titanium-lined stainless steel kettle, carry out oxidation leaching at a temperature of 140°C and a total pressure of 0.6 Mpa, react for 4 hours and then filter to obtain an oxidation leaching solution, nickel, cobalt, Copper is leached efficiently.

[0020] Operation results: the slag rate is 1.5%, and the acidity of the solution after the reaction is 0.44mol / L.

[0021] Reaction result: the leaching rate of copper is 99.48%, the leaching rate of cobalt is 99.9%, and the leaching rate of nickel is 99.9%.

Embodiment 3

[0022] Example 3: Slurry 200g of Cuban nickel-cobalt raw material with 1.6 liters of aqueous solution adding 20ml of sulfuric acid, add 2L titanium-lined stainless steel kettle, carry out oxidation leaching at a temperature of 150°C and a total pressure of 0.8Mpa, filter and wash after a reaction time of 3 hours, and obtain oxidized In the leaching solution, nickel, cobalt and copper are efficiently leached.

[0023] Operation results: the slag rate is 1.1%, and the acidity of the solution after the reaction is 0.69mol / L.

[0024] Reaction result: the leaching rate of copper is 99.88%, the leaching rate of cobalt is 99.89%, and the leaching rate of nickel is 99.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com