Method for producing spherical cobalt carbonate by continuous process

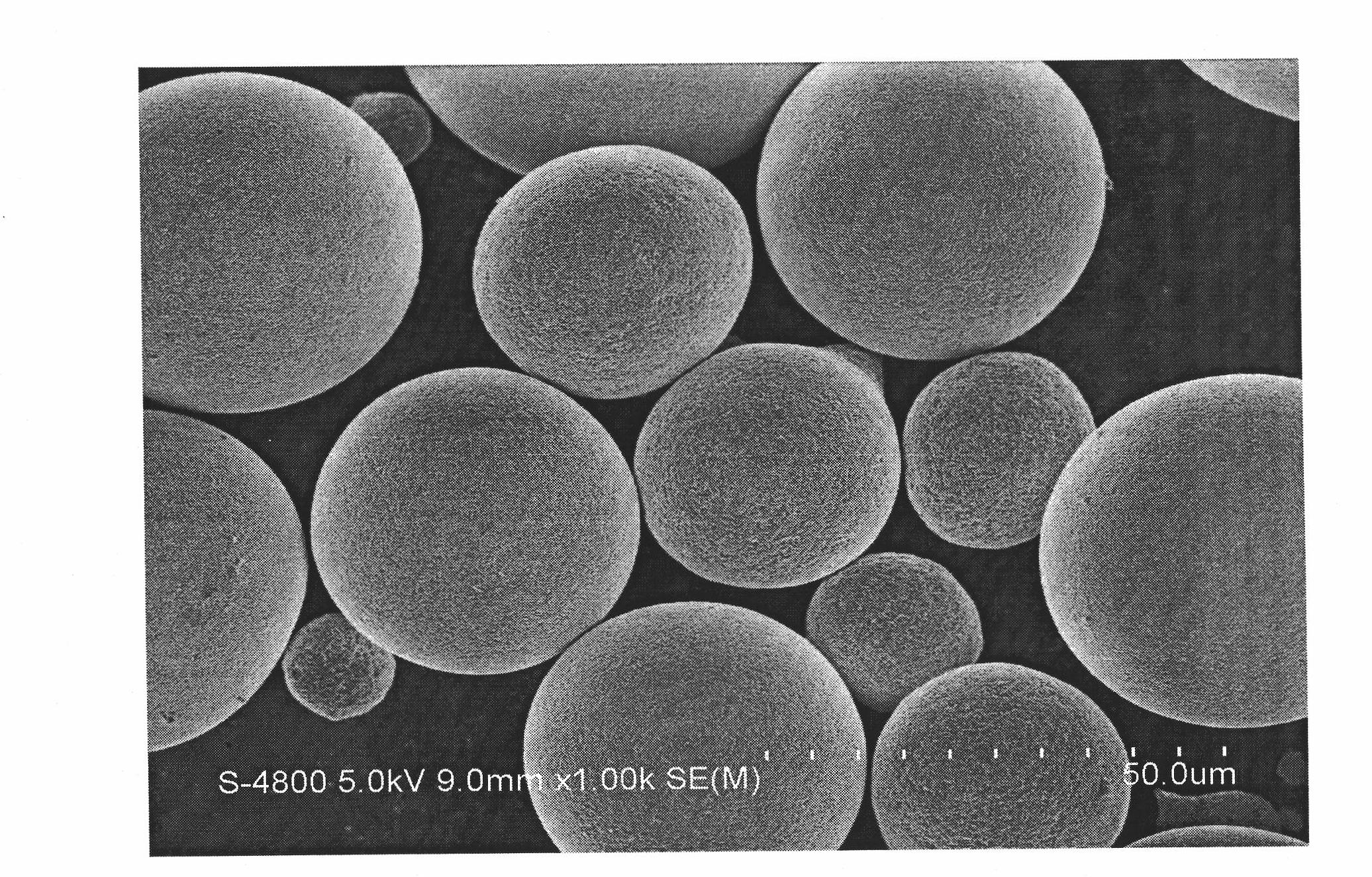

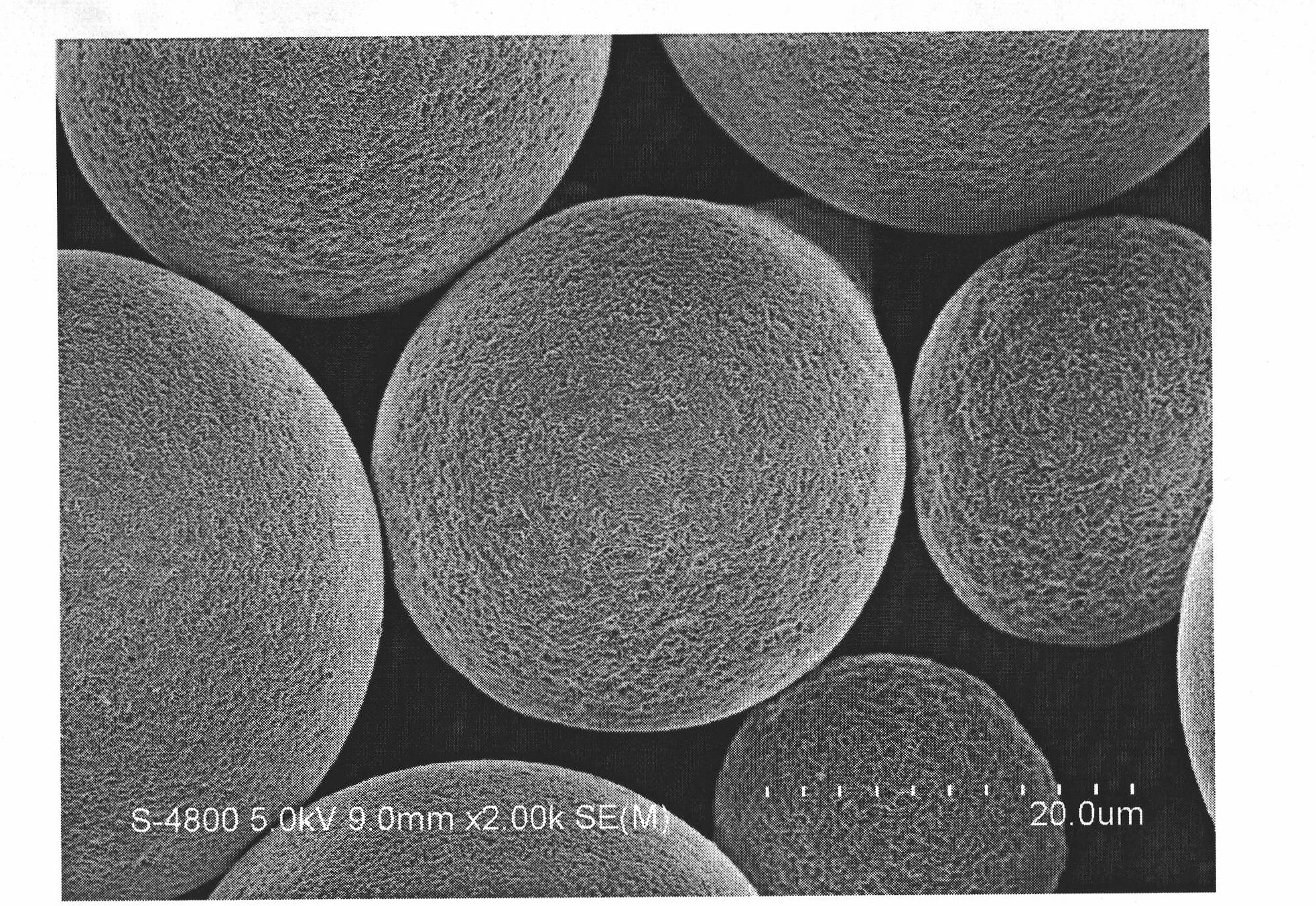

A cobalt carbonate, continuous process technology, applied in the direction of cobalt carbonate, can solve the problems of low production efficiency, can only be produced in batches, and many process steps, and achieve good spheroidization, good crystal nucleus structure consistency, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

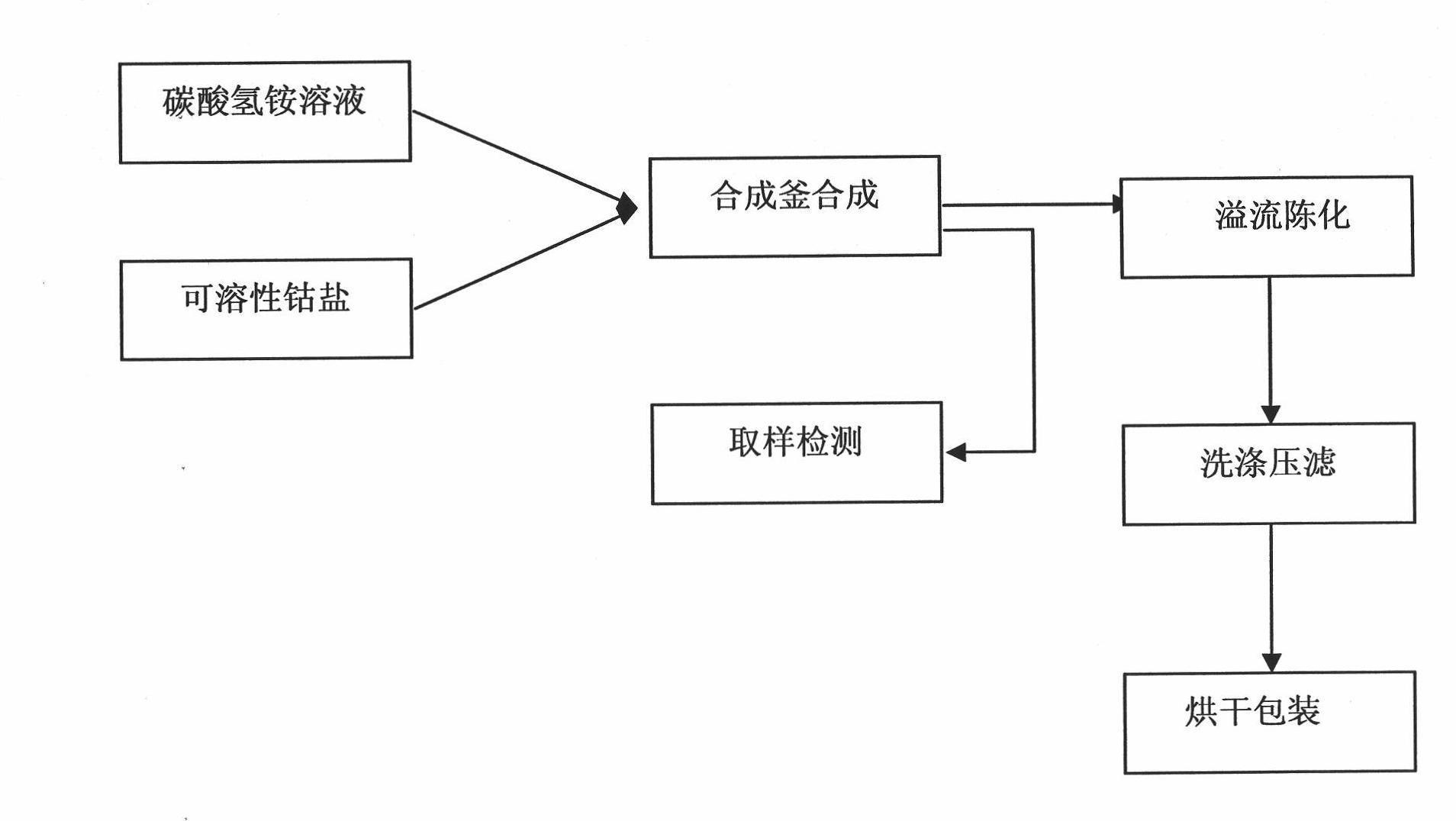

[0024] figure 1 Shown is a kind of continuous method production spherical cobalt carbonate method, comprises the following steps:

[0025] a. prepare cobalt sulfate solution;

[0026] Add 1.5m to the preparation tank 3 Open the preparation tank to stir, put a certain amount of cobalt sulfate into the preparation tank, and replenish water to 3.5m 3 After stirring for one hour, the cobalt salt was fully dissolved and then sampled for testing, and the cobalt concentration was pumped into the cobalt sulfate solution storage tank when the cobalt concentration was 80 ± 5g / L;

[0027] b. Preparation of ammonium bicarbonate solution

[0028] Add 1.5m to the preparation tank 3 Open the preparation tank to stir, slowly put a certain amount of ammonium bicarbonate into the preparation tank, add water to 3.5m after finishing cobalt sulfate 3 After stirring for one hour, the ammonium bicarbonate was fully dissolved and then sampled for testing. When the ammonium bicarbonate concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com