Method for preparing ultra-pure cobalt board

A pure cobalt plate, ultra-high technology, applied in the field of preparation of ultra-high-purity cobalt plate, can solve the problems such as cobalt is difficult to realize, and achieve the effect of internal density, smooth surface and broad market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

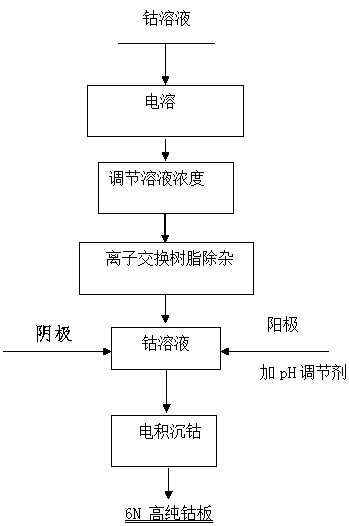

Method used

Image

Examples

Embodiment 1

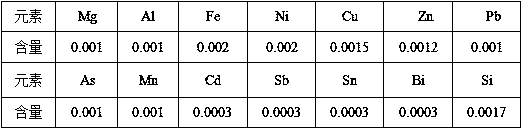

[0026] A method for preparing an ultra-high-purity cobalt plate. Add 500L of 3mol / L sulfuric acid to the electrolytic tank, use the electrolytic cobalt as the anode, and use the titanium mesh as the cathode. The given current is 150A, and the cell voltage is controlled to 1.5V. Stop electrolytic dissolution when the solution pH in the dissolution tank reaches 3.5, and the main control impurity content index in the cobalt sulfate solution prepared by electrolysis is as shown in the table:

[0027] Table 2 Chemical analysis results of cobalt sulfate solution (g / L)

[0028]

Embodiment 2

[0030] A method for preparing an ultra-high-purity cobalt plate. Add 500L of 3mol / L sulfuric acid to the electrolytic tank, use the electrolytic cobalt as the anode, and use the titanium mesh as the cathode. The given current is 150A, and the tank voltage is controlled to 1.7V. Stop electrolytic dissolution when the solution pH in the dissolution tank reaches 3.5, and the main control impurity content index in the cobalt sulfate solution prepared by electrolysis is as shown in the table:

[0031] Table 3 Chemical analysis results of cobalt sulfate solution (g / L)

[0032]

Embodiment 3

[0034] Influence of purification speed of cobalt sulfate solution on purification effect:

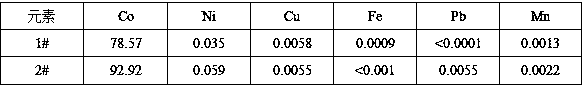

[0035] a. Adjust the concentration of the cobalt sulfate stock solution prepared by electrolytic dissolution to 80g / L, and control the pH to 4. The cobalt sulfate stock solution is absorbed and removed by the anion resin 711 in the ion exchange device to obtain a high-purity cobalt sulfate solution, and the solution is controlled to flow out The flow rate of the ion exchange device is 15L / h, which realizes the deep purification of the cobalt sulfate solution. The composition of the purified cobalt sulfate solution is:

[0036] Table 4 Test results of cobalt sulfate solution after deep purification (g / L)

[0037]

[0038] b. Adjust the concentration of the cobalt sulfate stock solution prepared by electrolytic dissolution to 80g / L, control the pH to 4, and absorb the cobalt sulfate stock solution through the anion resin 711 in the ion exchange device to obtain a high-purity cobalt sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com