A kind of flexible conductive film and preparation method thereof

A flexible conductive and thin film technology, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of low tensile strength of flexible cellulose films, which affects the conductivity of films Uniformity, graphene surface damage and other issues, to achieve the effect of uniform and dense deposition, good conductivity, and accurate thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

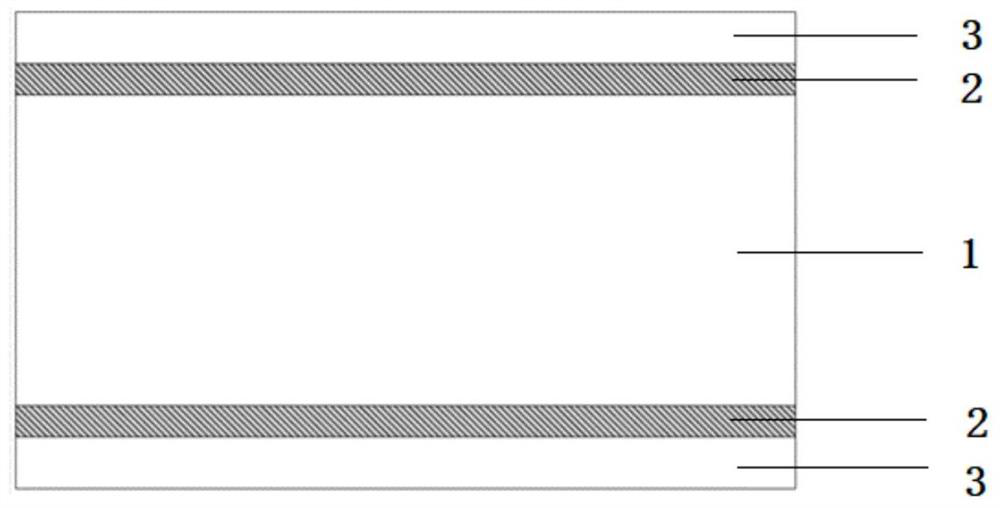

[0044] The flexible conductive film is prepared by the following steps:

[0045] 1. Vacuum the equipment to 8.0×10 -4 mba, then heat the equipment to a certain temperature, and pre-melt the wire film material at a wire feeding speed of 250mm / min;

[0046] 2. The PET polymer film is injected with a mixed gas of oxygen and argon with a ratio of 1:0.1-10 for plasma blowing treatment, and the surface of the film is oxidized to add oxygen-containing functional groups;

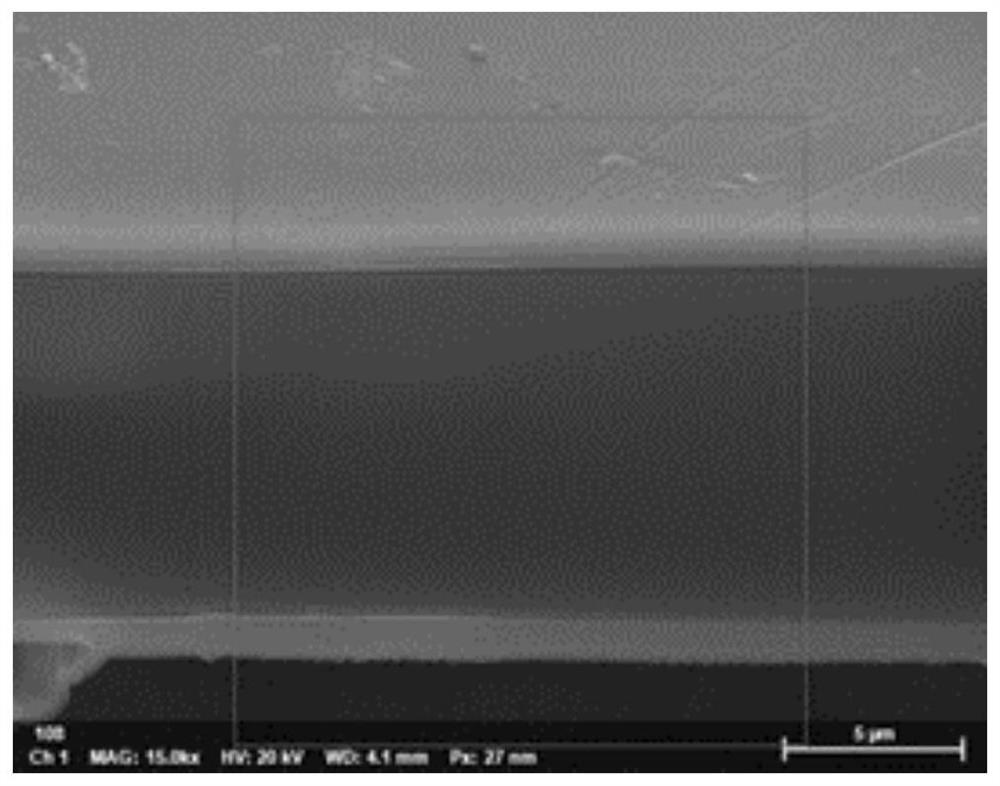

[0047] 3. After the treatment, remove the baffle for evaporation, and deposit a metal reinforcement layer with a thickness of 8nm on the polymer film substrate. The thickness of the reinforcement layer is controlled by the optical density probe. After the film thickness meets the requirements, use the baffle Cover the evaporation source and stop heating;

[0048] 4. After the film coating is completed, inflate the coating chamber, and take out the coating coil when the pressure in the chamber reaches atmospheric p...

Embodiment 2

[0053] In this embodiment, a flexible conductive film is prepared through the following steps:

[0054] 1. Vacuum the equipment to 8.0×10 -4 mba, then heat the equipment to a certain temperature, and pre-melt the wire film material at a wire feeding speed of 250mm / min;

[0055] 2. The PET polymer film is injected with a mixed gas of oxygen and argon with a ratio of 1:0.1-10 for plasma blowing treatment, and the surface of the film is oxidized to add oxygen-containing functional groups;

[0056] 3. After the treatment, remove the baffle for evaporation, and deposit a metal reinforcement layer with a thickness of 8nm on the polymer film substrate. The thickness of the reinforcement layer is controlled by the optical density probe. After the film thickness meets the requirements, use the baffle Cover the evaporation source and stop heating;

[0057] 4. After the film coating is completed, inflate the coating chamber, and take out the coating coil when the pressure in the chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com