Solar cell and preparation method thereof

A technology of solar cells and silicon cells, applied in the field of solar cells, can solve the problems of deteriorating the long-term stability of perovskite cells, affecting the performance of perovskite devices, and mismatching components of perovskite layers, so as to inhibit ion migration, Effect of reducing light reflection loss and dense deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

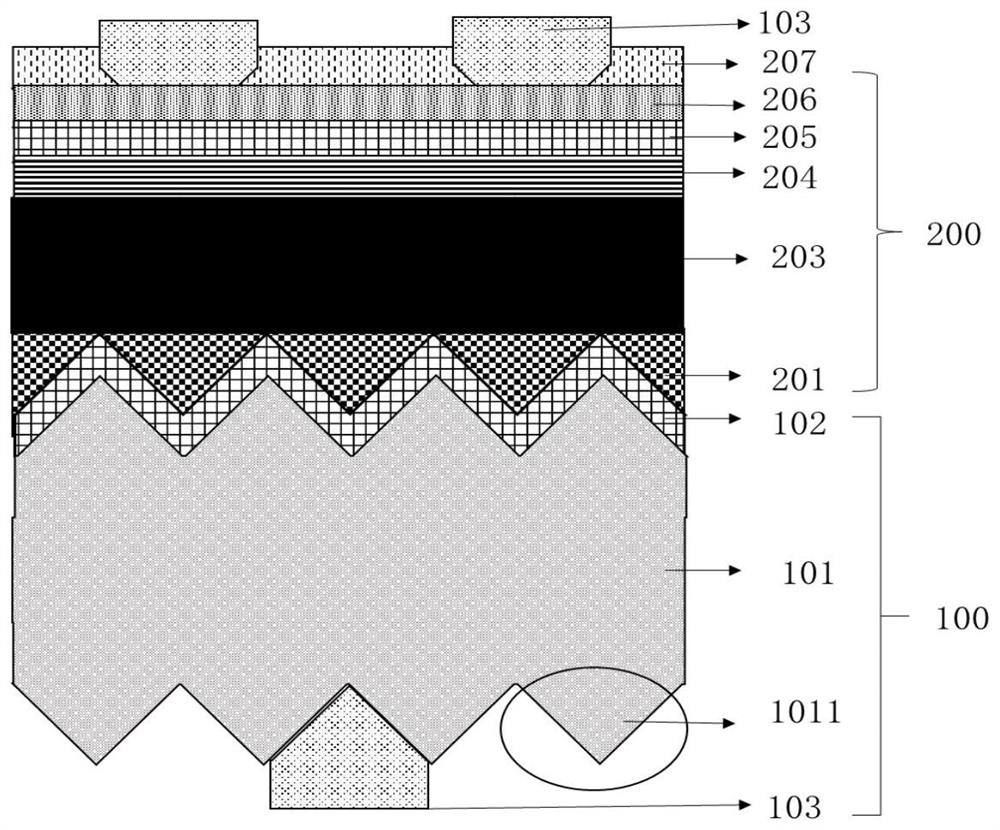

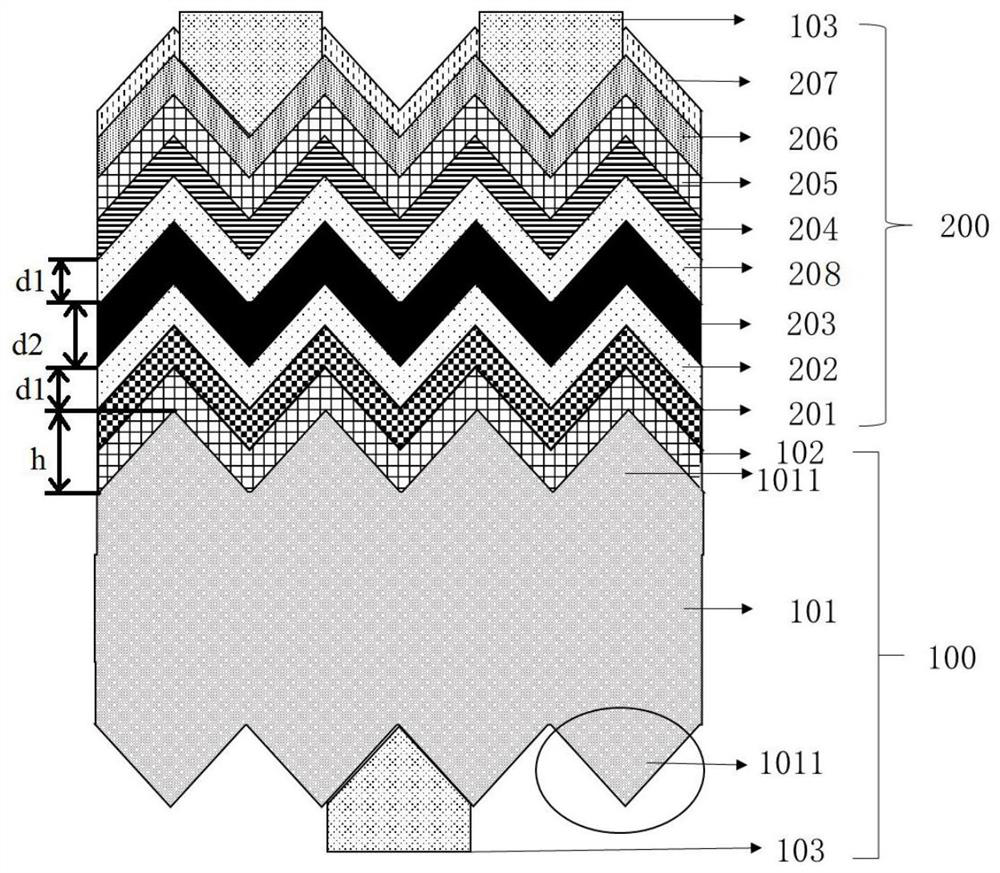

[0081] The method for preparing the first stacked perovskite battery includes the following steps:

[0082] Step 1: providing the lower battery 100 with the suede structure 1011;

[0083] Step 2: forming a first carrier transport layer 201 on the surface of the lower battery 100;

[0084] Step 3: forming a first interface passivation layer 202 conformal to the textured structure 1011 on the surface of the first carrier transport layer 201 away from the lower battery 100 by vapor deposition;

[0085] Step 4: forming a perovskite absorption layer 203 on the surface of the first interface passivation layer 202 away from the first carrier transport layer 201;

[0086] Step 5: forming a second carrier transport layer 204 on the surface of the perovskite absorption layer 203 on the side away from the first interface passivation layer 202 .

[0087] In step 1, the silicon wafer is sequentially subjected to polishing, texturing, coating, cleaning and tunnel junction procedures to form...

Embodiment 1

[0239] This embodiment is the first type of stacked perovskite battery, and the preparation method includes the following steps:

[0240] Step 1: providing the lower battery 100 with the suede structure 1011;

[0241] Specifically, an n-type silicon wafer of 180 μm and a resistivity of 5Ω.cm commercial grade M2 was polished, textured, and cleaned to form a silicon wafer substrate with a textured structure 1011 through alkaline solution polishing, and PECVD was used on the light incident side of the cell. (Plasma Enhanced Chemical Vapor Deposition, plasma enhanced chemical vapor deposition method) process to prepare the tunneling layer 102, the tunneling layer 102 can use PECVD to deposit uc-Si-p respectively + Layers and uc-Si-n + The layer forms a tunnel junction with a thickness of 30 nm.

[0242] Step 2: forming a first carrier transport layer 201 on the surface of the lower battery 100;

[0243] Specifically, by vacuum evaporation (the rate of evaporation is ) On th...

Embodiment 2

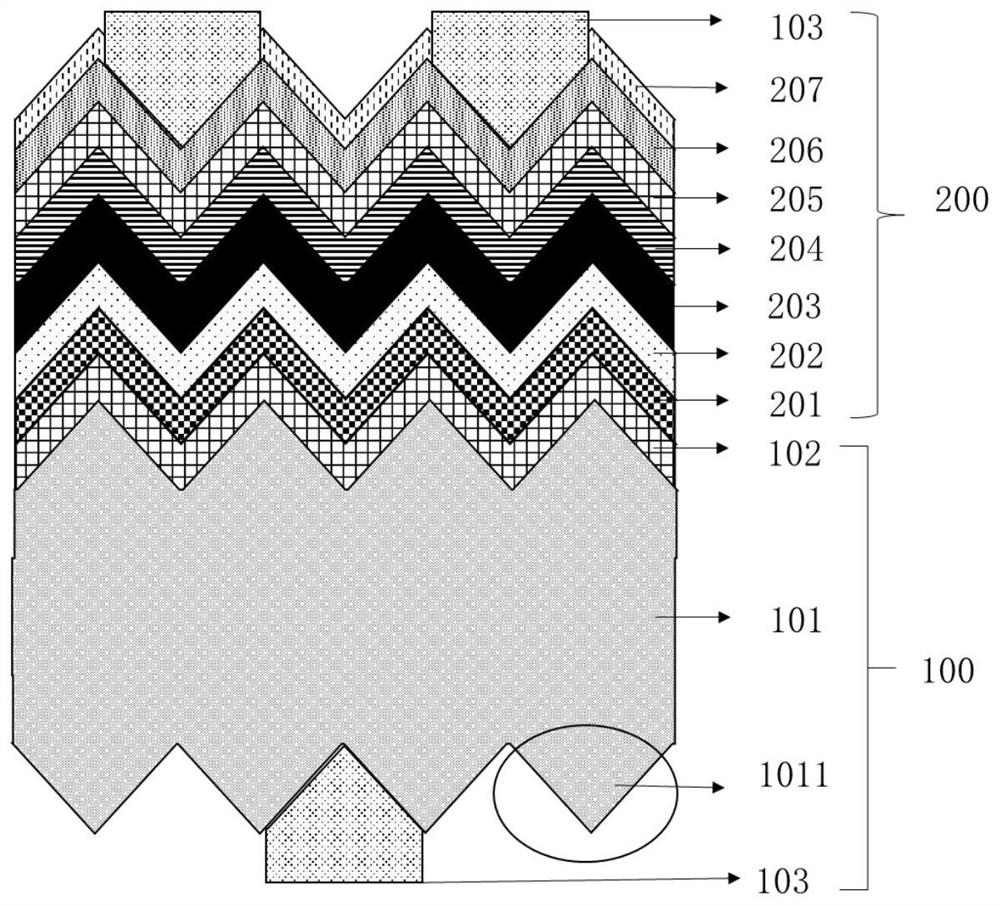

[0256] This embodiment is a second type of stacked perovskite battery, and the preparation method includes the following steps:

[0257] Step 1: providing the lower battery 100 with the suede structure 1011;

[0258] Specifically, an n-type silicon wafer of 180 μm and a resistivity of 5Ω.cm commercial grade M2 was polished, textured, and cleaned to form a silicon wafer substrate with a textured structure 1011 through alkaline solution polishing, and PECVD was used on the light incident side of the cell. (Plasma Enhanced Chemical Vapor Deposition, Plasma Enhanced Chemical Vapor Deposition) process to prepare the tunneling layer 102, the tunneling layer 102 can use PECVD to deposit uc-Si-p respectively + Layers and uc-Si-n + The layer forms a tunnel junction with a thickness of 30 nm.

[0259] Step 2: forming a first carrier transport layer 201 on the surface of the lower battery 100;

[0260] Specifically, by vacuum evaporation (the rate of evaporation is ) On the tunnel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com