A kind of negative electrode current collector of lithium metal secondary battery and preparation method thereof

A secondary battery, current collector technology, applied in battery electrodes, lithium batteries, electrode carriers/current collectors, etc., can solve problems such as uniform deposition that is not bottom-up, achieve easy control, simple operation, and reduce actual current. The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

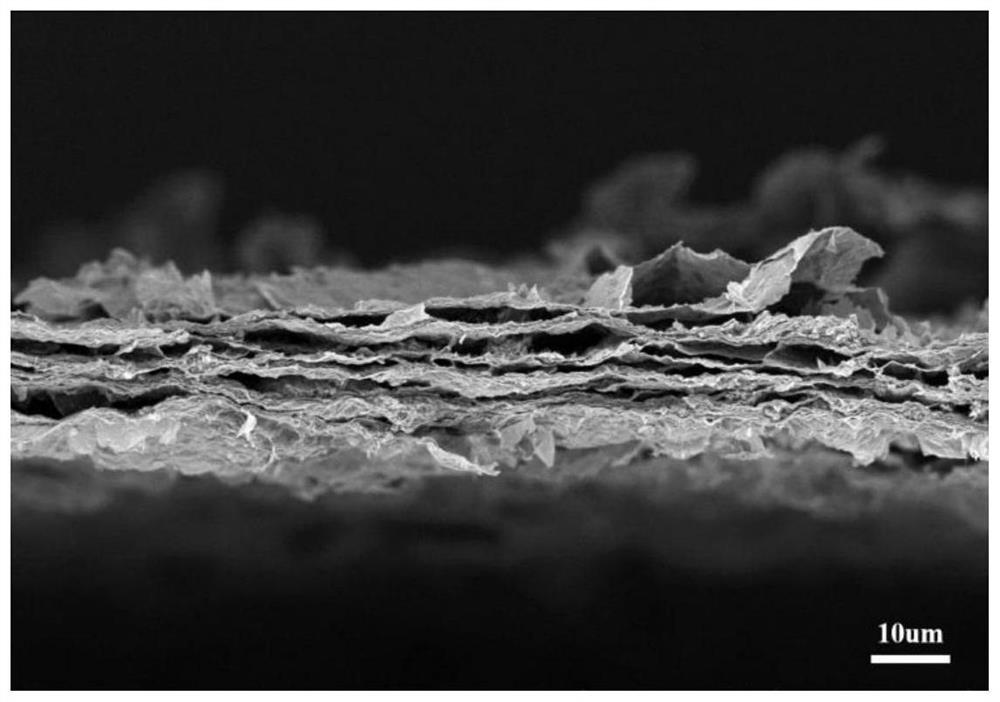

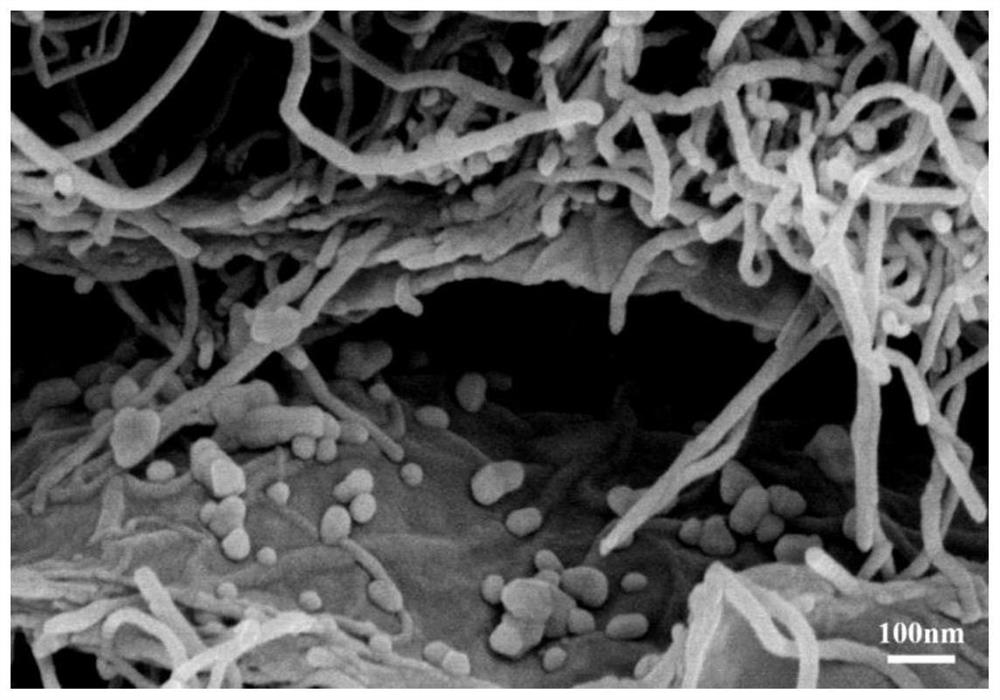

[0035] (1) Add 10 mg of graphene oxide solution containing 10 mg of graphene oxide sheets with a size of 20 μm to 50 μm and a concentration of 10 mg / mL into 4 mL of deionized water, stir magnetically for 30 minutes and then ultrasonicate for 120 minutes to form an aqueous solution of graphene oxide. The aqueous solution of graphene is prepared three parts;

[0036] (2) Add 80 mg, 40 mg, and 20 mg of zinc acetate into three portions of 5 mL deionized water one by one, and add 2 mg of carbon nanotubes with a length of 0.5 μm to 2 μm to the three portions of zinc acetate aqueous solution, and stir magnetically for 30 minutes. After ultrasonication for 120min, three carbon nanotube suspensions were obtained;

[0037] (3) Three parts of graphene oxide aqueous solution and three parts of carbon nanotube suspensions were mixed one by one, magnetically stirred for 30 minutes and then ultrasonicated for 60 minutes to obtain three parts of mixed suspensions;

[0038] (4) Suction filter...

Embodiment 2

[0044] (1) Add 10 mg of graphene oxide solution containing 10 mg of graphene oxide sheets with a size of 20 μm to 50 μm and a concentration of 10 mg / mL into 4 mL of deionized water, stir magnetically for 30 minutes and then ultrasonicate for 120 minutes to form an aqueous solution of graphene oxide. The aqueous solution of graphene is prepared three parts;

[0045] (2) Add 100 mg, 50 mg, and 25 mg of zinc acetate into three portions of 5 mL deionized water one by one, and add 2 mg of carbon nanotubes with a length of 0.5 μm to 2 μm to the three portions of zinc acetate aqueous solution, and stir magnetically for 30 minutes. After ultrasonication for 120min, three carbon nanotube suspensions were obtained;

[0046] (3) Three parts of graphene oxide aqueous solution and three parts of carbon nanotube suspensions were mixed one by one, magnetically stirred for 30 minutes and then ultrasonicated for 60 minutes to obtain three parts of mixed suspensions;

[0047] (4) Suction filte...

Embodiment 3

[0052] (1) Add 10 mg of graphene oxide solution containing 10 mg of graphene oxide sheets with a size of 20 μm to 50 μm and a concentration of 10 mg / mL into 4 mL of deionized water, stir magnetically for 30 minutes and then ultrasonicate for 120 minutes to form an aqueous solution of graphene oxide. The aqueous solution of graphene is prepared three parts;

[0053] (2) Add 80 mg, 40 mg, and 20 mg of zinc acetate into three portions of 5 mL deionized water one by one, and add 1 mg of carbon nanotubes with a length of 0.5 μm to 2 μm to the three portions of zinc acetate aqueous solution, and stir magnetically for 30 minutes After ultrasonication for 120min, three carbon nanotube suspensions were obtained;

[0054] (3) Three parts of graphene oxide aqueous solution and three parts of carbon nanotube suspensions were mixed one by one, magnetically stirred for 30 minutes and then ultrasonicated for 60 minutes to obtain three parts of mixed suspensions;

[0055] (4) Suction filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com