Phosphorus quantum dot composite porous hard carbon material and its preparation method and application

A technology of phosphorus quantum and porous carbon, which is applied to phosphorus quantum dot composite porous hard carbon materials and their preparation, and the application field of lithium metal ion battery anode materials, which can solve the large volume change, unstable structure, and easy pulverization failure of phosphorus materials and other issues, to achieve the effect of wide material sources, low cost, and improved rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

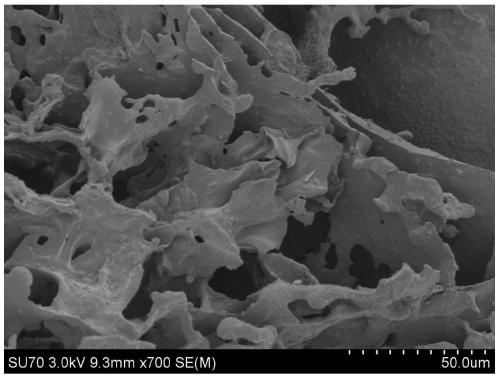

[0038] (1) Weigh 10g of soybeans, mix them with 100ml of deionized water, and make high-concentration soybean milk (syrup precursor). Soymilk can be pressed into "tofu" with different densities by using the method of making tofu with brine. After moderate drying, slice and freeze-dry in a freeze dryer for 5 days, then react in a tube furnace at 1200°C for 2 hours under the protection of high-purity argon to obtain Soy-made porous carbon material after carbonization.

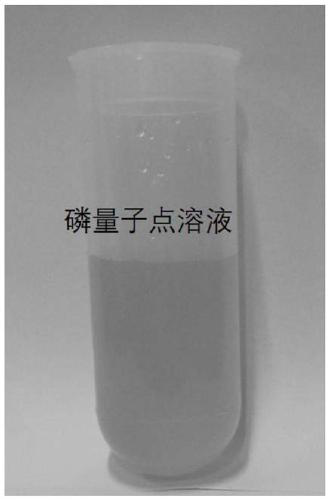

[0039] (2) Put 8g red phosphorus and 70ml deionized water in a hydrothermal reaction kettle, 200 o C under hydrothermal reaction for 24h, the hydrothermal reaction was carried out, and then the precipitate was collected by filtration. Prepare 0.5mol L -1 urea aqueous solution, dissolve the precipitate in urea aqueous solution, settle for 5min and take the supernatant. Use a centrifuge to further disperse and centrifuge the supernatant at 8000 r / min for 30 minutes to obtain the final supernatant containing phos...

Embodiment 2

[0044] (1) Weigh 10g of lobster shell, mix it with 100ml of deionized water and beat it into a slurry precursor at high speed. Put the slurry precursor into a freeze dryer for 4 days and freeze-dry it for 4 days, then react in a tube furnace at 1000 °C for 2 h under the protection of high-purity argon to obtain a carbonized porous carbon material.

[0045] (2) Put 5g red phosphorus and 65ml deionized water in a hydrothermal reaction kettle, 200 o C under hydrothermal reaction for 36h, hydrothermal reaction was carried out, and then the precipitate was collected by filtration. Prepare 1 mol L -1 urea aqueous solution, the precipitate was dissolved in urea aqueous solution, and the supernatant was taken after settling for 15 minutes. Use a centrifuge to further disperse and centrifuge the supernatant at 6000 r / min for 40 minutes to obtain the final supernatant containing phosphorus quantum dots.

[0046] (3) Mix 2 g of the carbonized porous carbon material with 10 ml of the s...

Embodiment 3

[0048] (1) Weigh 50g of apples, mix with 50ml of deionized water and make a slurry precursor. The slurry precursor was placed in a freeze dryer for 5 days and then reacted in a tube furnace at 1200 °C for 2 h under the protection of high-purity argon to obtain N-doped porous carbon.

[0049] (2) Put 8g red phosphorus and 70ml deionized water in a hydrothermal reaction kettle, 150 o C under hydrothermal reaction for 40 h, and the precipitate was collected by filtration after the hydrothermal reaction. Prepare 0.1mol L -1 urea aqueous solution, dissolve the precipitate in urea aqueous solution, settle for 5min and take the supernatant. Use a centrifuge to further disperse and centrifuge the supernatant at 8000 r / min for 30 minutes to obtain the final supernatant containing phosphorus quantum dots.

[0050] (3) Mix 1 g of the carbonized porous carbon material with 10 ml of the supernatant and dry it to obtain a porous carbon material doped with phosphorus quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com