Pure nickel or nickel-based alloy plating layer with nano twin crystal structure and electro-deposition preparation method of pure nickel or nickel-based alloy plating layer

A nano-twin, nickel-based alloy technology, applied in the field of pure nickel or nickel-based alloy plating and its electrodeposition preparation, to achieve the effects of high versatility, unique microstructure, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

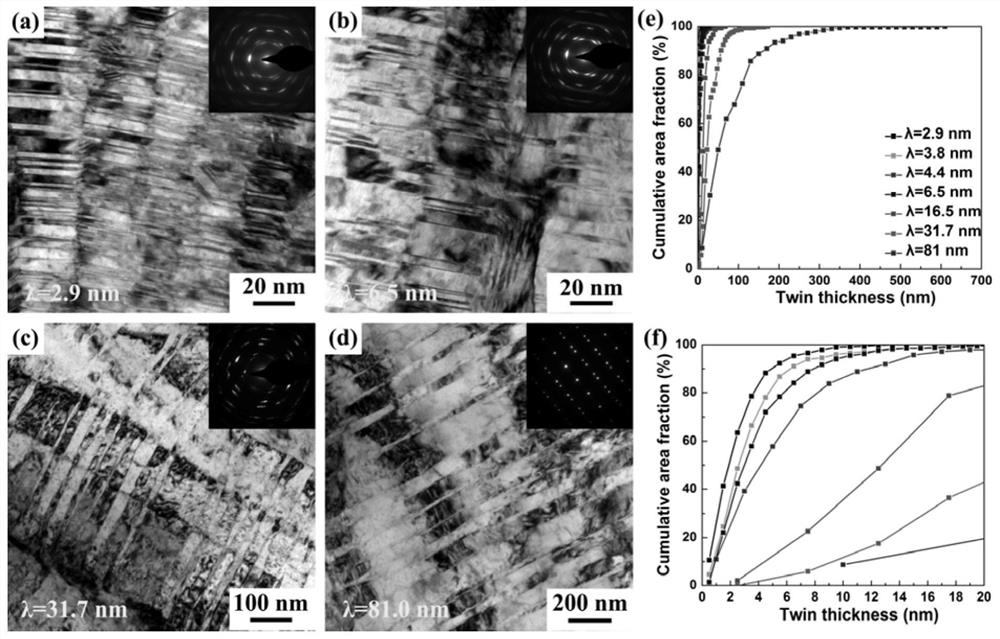

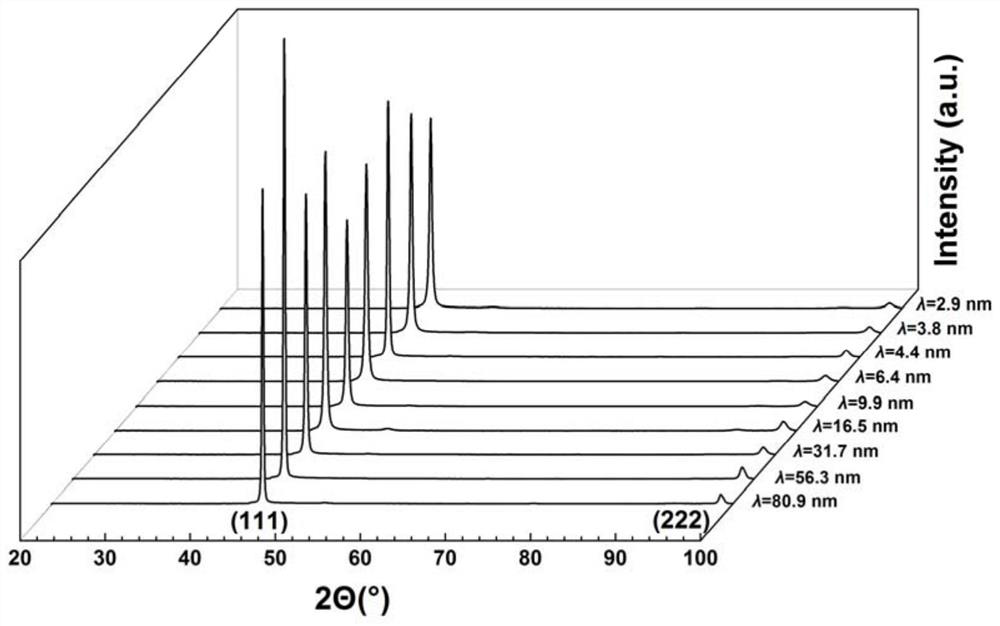

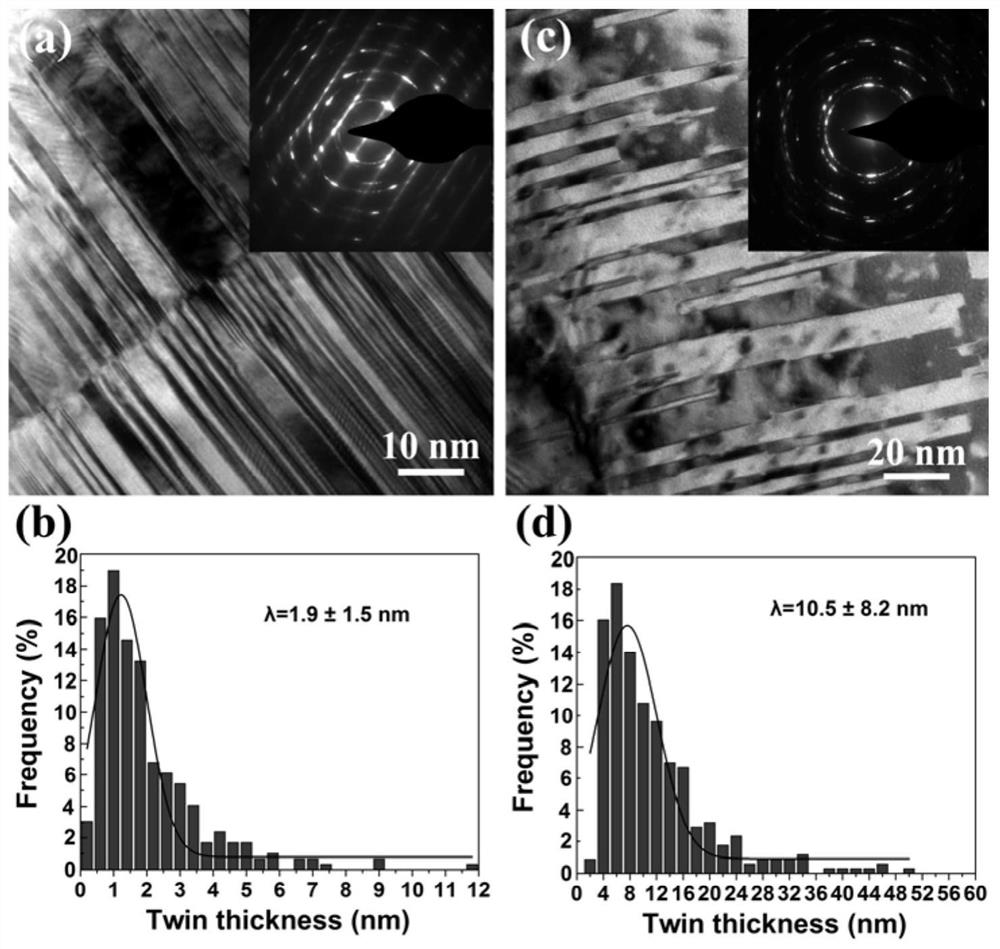

Examples

Embodiment 1

[0041] In this embodiment, a citrate system plating solution is used to electrodeposit a nano-twinned pure nickel coating.

[0042] Electrodeposition equipment: DC power supply.

[0043] Electrolyte raw material composition: 400g / L nickel sulfate hexahydrate, 40g / L nickel chloride hexahydrate, 40g / L sodium citrate dihydrate; additives are sodium lauryl sulfate 0.05g / L, sodium saccharin 2.0g / L , 1,4 butynediol 0.64g / L; the above reagents were all dissolved in deionized water, stirred and dissolved and then filtered through filter paper; then the pH value was adjusted to 6.0 with NaOH and sulfuric acid solution with a concentration of 10wt.%.

[0044] Cathode and anode requirements: the anode is a pure nickel plate with a purity of 99.6wt.%, and the cathode is a nickel substrate after surface degreasing and sensitization treatment.

[0045] 2) Electrolysis process parameters: DC current density is 60mA / cm 2 , the electrolyte temperature is 60±1°C, the area ratio of cathode and...

Embodiment 2

[0052] This embodiment adopts citrate system plating solution to electrodeposit nano-twin crystal pure nickel coating:

[0053] Electrodeposition equipment: DC power supply

[0054] Electrolyte raw material composition: 200g / L nickel sulfate hexahydrate, 60g / L nickel chloride hexahydrate, 10g / L sodium citrate dihydrate; additives are sodium lauryl sulfate 0.06g / L, sodium saccharin 2.0g / L , 0.74g / L of 1,4 butynediol, 0.07g / L of glacial acetic acid; the above reagents were all dissolved in deionized water, stirred and dissolved, and then filtered through filter paper; then the pH value was adjusted to 6.7;

[0055] Cathode and anode requirements: the anode is a pure nickel plate with a purity of 99.6wt.%, and the cathode is a nickel substrate after surface degreasing and sensitization treatment.

[0056] 2) Electrolysis process parameters: DC current density is 70mA / cm 2 , the temperature of the electrolyte is 65±1°C, the area ratio of cathode and anode is 1:50, the distance ...

Embodiment 3

[0059] In this embodiment, a citrate system plating solution is used to electrodeposit a nano-twinned pure nickel coating.

[0060] Electrodeposition equipment: DC power supply

[0061] Electrolyte raw material composition: 120g / L nickel sulfate hexahydrate, 20g / L nickel chloride hexahydrate, 60g / L sodium citrate dihydrate; additives are sodium lauryl sulfate 0.05g / L, sodium saccharin 1.0g / L , 1,4 butynediol 0.64g / L; the above reagents were all dissolved in deionized water, stirred and dissolved, and filtered through filter paper; then the pH value was adjusted to 6.4 with 10% NaOH and sulfuric acid solution;

[0062] 2) Electrolysis process parameters: DC current density is 80mA / cm 2 , the electrolyte temperature is 60±1°C, the area ratio of cathode and anode is 1:50, the distance between cathode and anode is 60mm, the electrolyte is stirred by magnetic force, the stirring speed is 1500r / min, and the electrodeposition time: 6h.

[0063] 3) This process can produce a columna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com