Method for separating bright molybdenum and brass in refractory molybdenum copper sulphide ore

A technology for sulfide ore and brass, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of increasing processing consumption, affecting the environment, affecting the recovery rate of brass, etc., to reduce the consumption of chemicals, reduce The effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

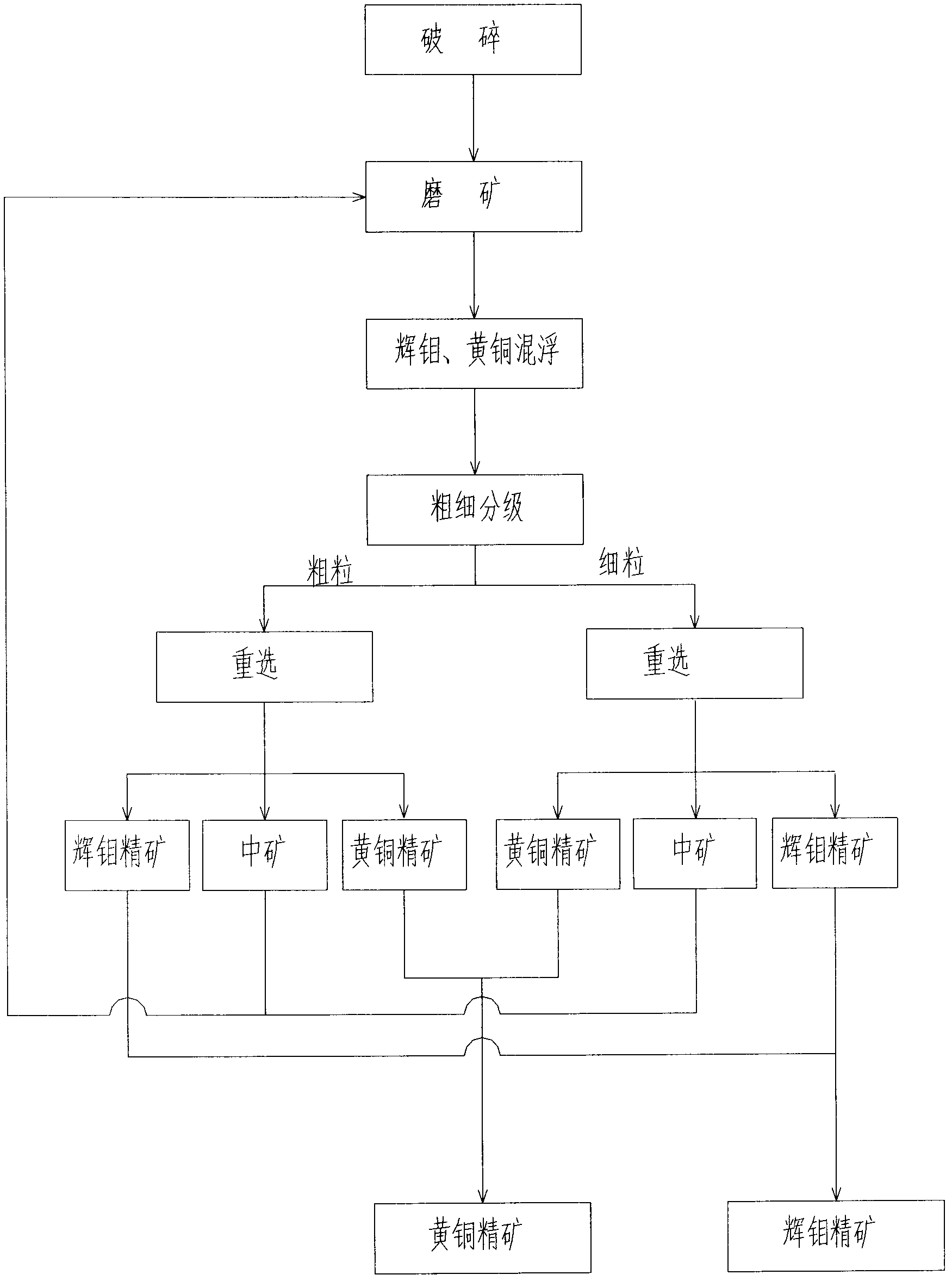

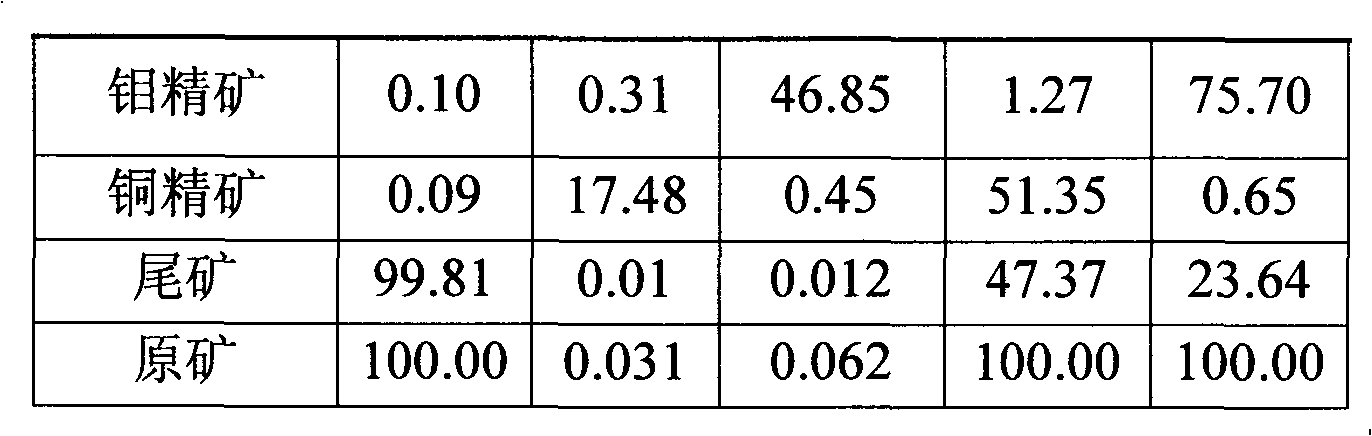

[0024] Embodiment 1: A method for separating molybdenite and brass from refractory molybdenite and chalcopyrite: refractory molybdenite and chalcopyrite, the most minerals in the ore are pyrite, followed by molybdenum Mineral ore, the rest are chalcopyrite, etc., trace amounts are rhenium, silver, gold ore, the grade of molybdenum is 0.08%, and the grade of copper is 0.04%. Molybdenum, copper, and rhenium can be recycled comprehensively. The conditions of different places are different, and the corresponding various minerals The content varies greatly. The purpose of this embodiment is to separate molybdenite and brass from refractory molybdenite and chalcopyrite. Among them, classification, gravity separation, regrinding and flotation process are the key steps to separate molybdenite and chalcopyrite.

[0025] The ores used in this embodiment were molybdenite and chalcopyrite ores produced by Jindi Molybdenum Industry Co., Ltd., Abaga Banner, Inner Mongolia.

[0026] Table ...

Embodiment 2

[0038] Embodiment 2: the impact of re-election times on the rate of recovery

[0039] The function of gravity separation is mainly to separate qualified molybdenite powder and qualified chalcopyrite powder. Using the same beneficiation process as in Example 1, the results are shown in Table 3 by adjusting the impact of re-election times on the recovery rate. It can be seen that the recovery rate of copper increases with the increase of re-election times, but the recovery rate of molybdenum decreases; and after the third time, the recovery rate of copper has tended to be stable. Three times of re-election can realize the purpose of separating molybdenite and brass from refractory molybdenite and chalcopyrite in the present invention.

[0040] The impact of table 3 re-election times on molybdenum, copper recovery (molybdenum, copper separation stage)

[0041] Magnetic separation times (%)

[0042] Remarks: Molybdenum and copper flotation separation stage indicators a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com