Process for enriching oxygen in air by two-stage pressure swing adsorption

A technology of pressure swing adsorption and air, which is applied in separation methods, chemical instruments and methods, products, etc., and can solve the problems of high power consumption and investment, short cycle time, and low oxygen recovery rate of oxygen generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The feed gas in this example is air. The oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the first stage pressure swing adsorption device is controlled at 21 to 23% (V), and the oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the second stage pressure swing adsorption device is controlled at 93% (V) around (that is, the product is oxygen-enriched).

[0052] Component

O 2

N 2

Ar

CO 2

other

∑

Concentration (%) (V)

20.93

78.03

0.932

0.03

0.078

100

[0053] Temperature: ≤45℃

[0054] Pressure: 0.018MPa(G)

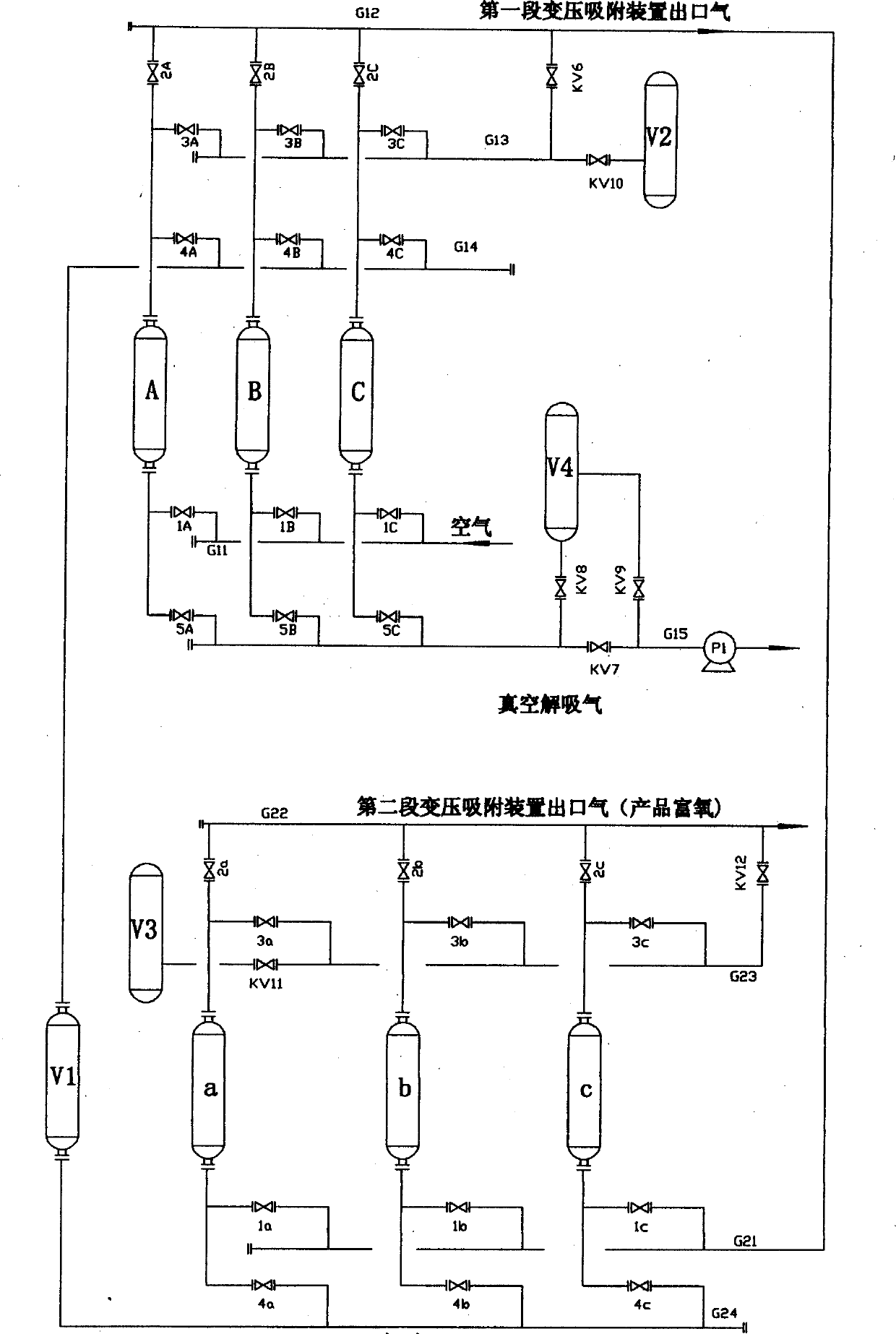

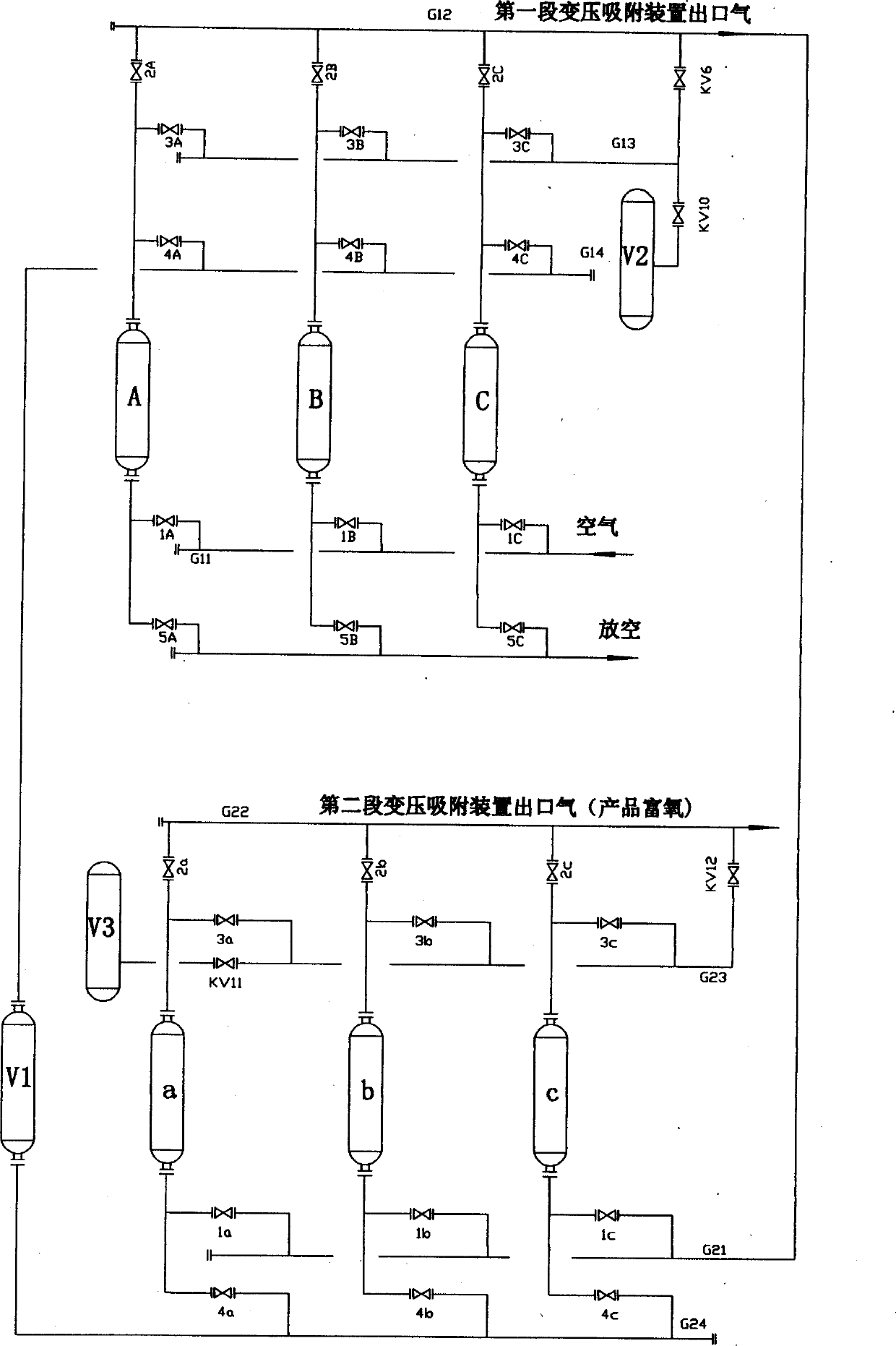

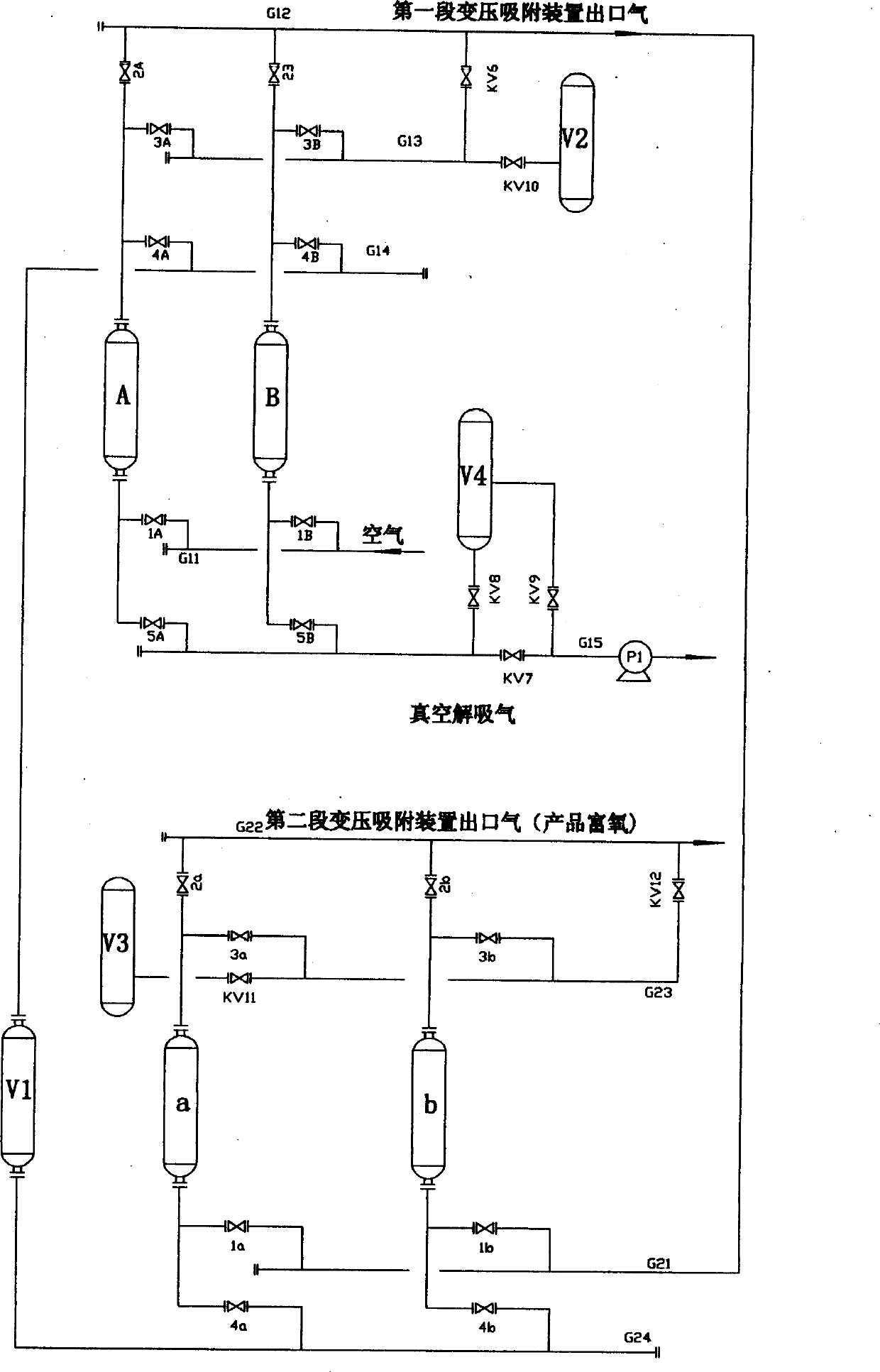

[0055] As shown in Figure 1, there are three adsorption towers A to C in total to form the first-stage pressure swing adsorption device, and there is also one vacuum buffer tank V4 and one pressure equalization buffer tank V2. The adsorbents loaded in the adsorption tower from bo...

Embodiment 2

[0085] The feed gas in this example is air. The oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the first stage pressure swing adsorption device is controlled at 45-50% (V), and the oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the second stage pressure swing adsorption device is controlled at 93% (V) around (that is, the product is oxygen-enriched).

[0086] The process flow chart of this embodiment, the operating program table of the process steps of the first-stage pressure swing adsorption device, and the operating program table of the process steps of the second-stage pressure swing adsorption device are the same as those of Embodiment 1.

[0087] Component

O 2

N 2

Ar

CO 2

other

∑

Concentration (%) (V)

20.93

78.03

0.932

0.03

0.078

100

[0088] As shown in Figure 1, there are three ads...

Embodiment 3

[0093] The feed gas in this example is air. The oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the first stage pressure swing adsorption device is controlled at 75-80% (V), and the oxygen concentration in the outlet gas of the adsorption tower in the adsorption step of the second stage pressure swing adsorption device is controlled at 93% (V) around (that is, the product is oxygen-enriched).

[0094] The process flow chart of this embodiment, the operating program table of the process steps of the first-stage pressure swing adsorption device, and the operating program table of the process steps of the second-stage pressure swing adsorption device are the same as those of Embodiment 1.

[0095] Component

O 2

N 2

Ar

CO 2

other

∑

Concentration (%) (V)

20.93

78.03

0.932

0.03

0.078

100

[0096] Temperature: ≤45℃

[0097] Pressure: 0.018MPa(G) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com