Move loading of general purpose type car engine cover, hinge installation equipment and production method

A technology for automobile engines and installation equipment, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve the problems of large storage area for fixtures, low production efficiency, and non-universal hinge installation fixtures, etc., and achieves the effect of saving investment and reducing storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

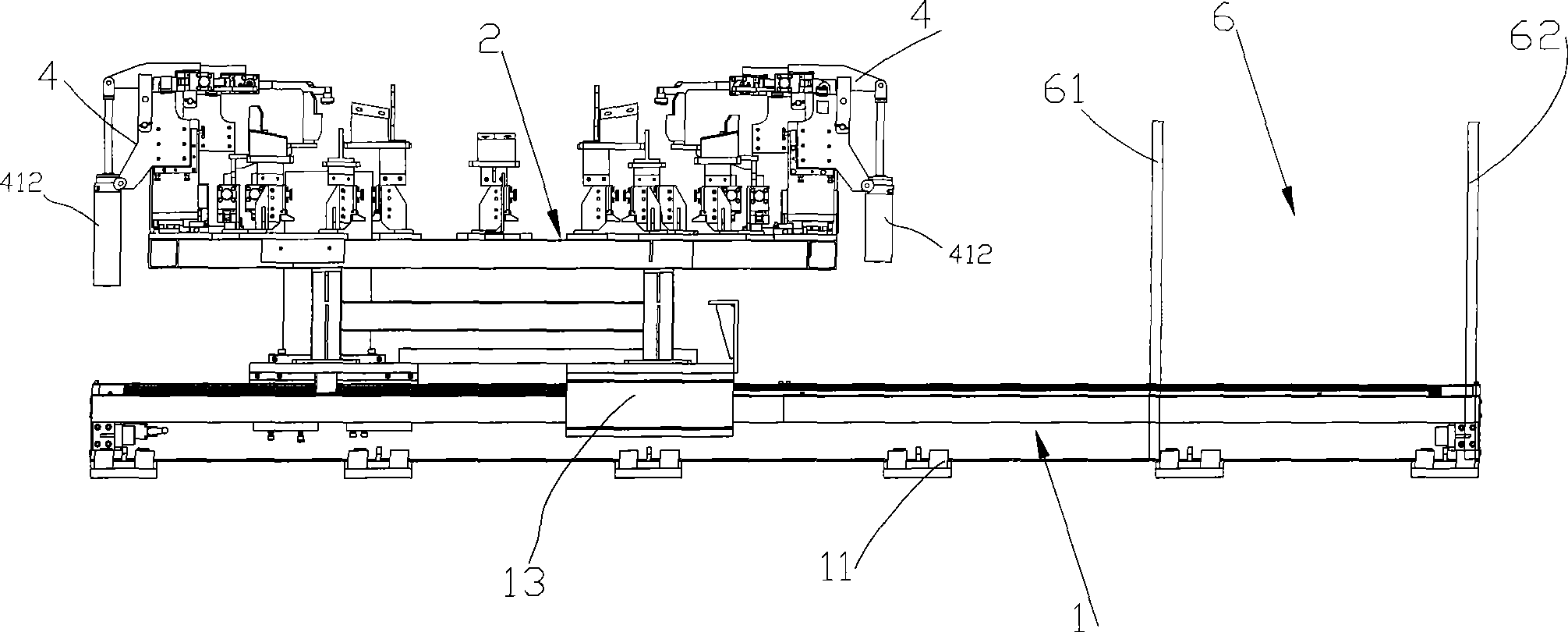

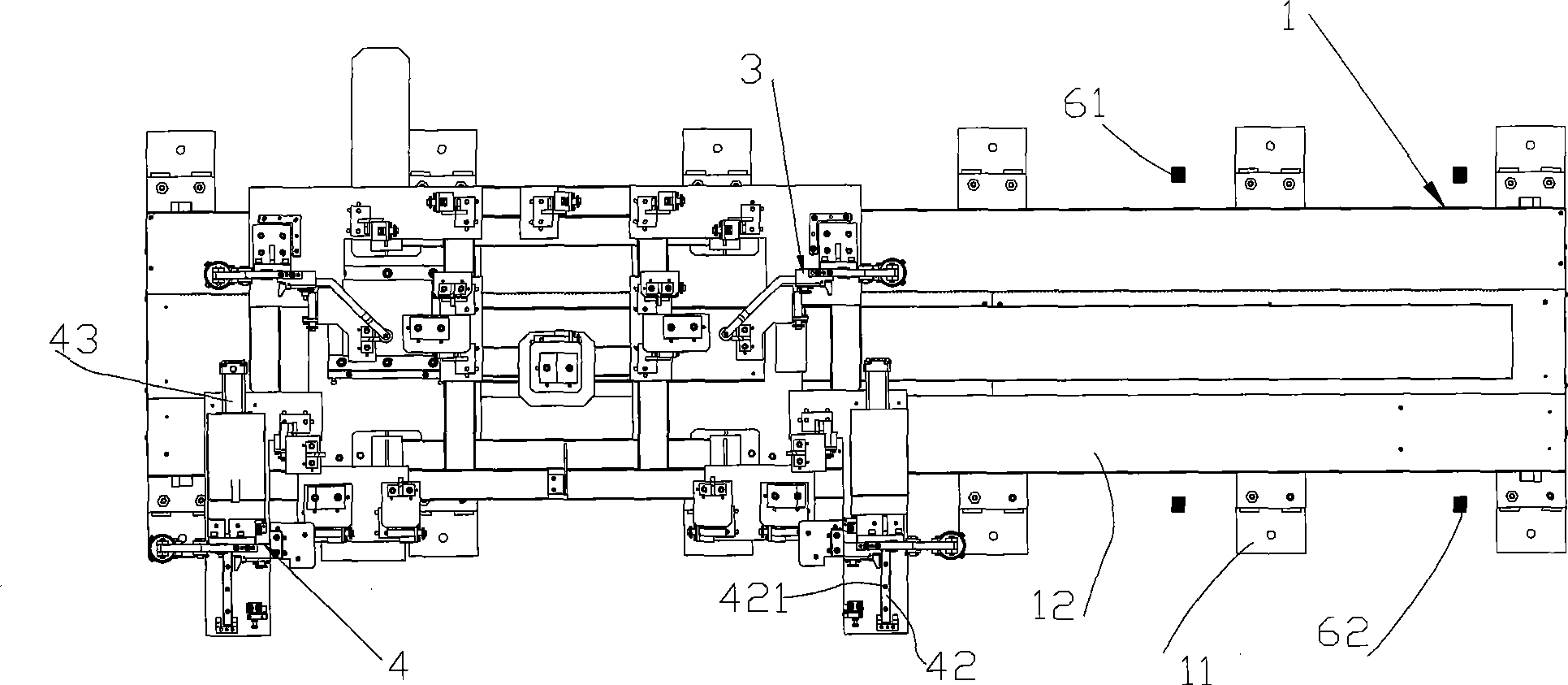

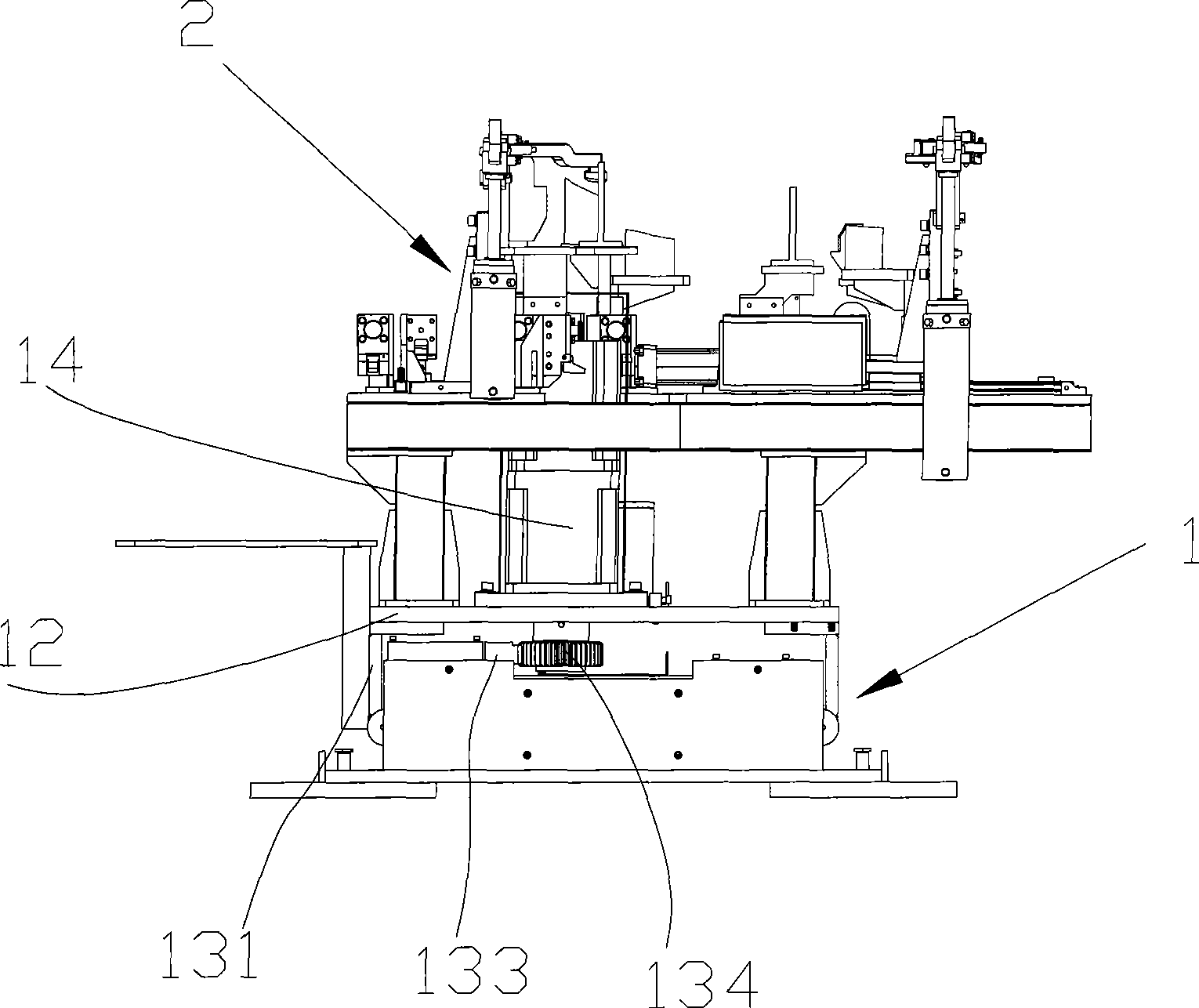

[0049] see figure 1 and figure 2 , Figure 4 and Figure 5 As shown, a general-purpose automobile engine cover transfer and hinge installation equipment is mainly composed of two parts, which are respectively transfer machine 1 and hinge installation platform 2). The transfer machine 1 and hinge installation platform 2 are combined Finally (realized by hard connection), the transfer machine 1 is responsible for providing the drive and realizing the transfer work of the equipment as a whole, and the hinge installation table 2 realizes the online clamping detection and hinge installation of workpieces of various models. The specific description is as follows:

[0050] Including: transfer machine 1, the transfer machine 1 includes a bracket 11 and a guide rail 12 arranged on the bracket 11, a slide mechanism 13 is provided on the guide rail 12, and a hinge mounting platform 2 is provided on the slide mechanism 13 and is used for controlling The servo motor 14 operated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com