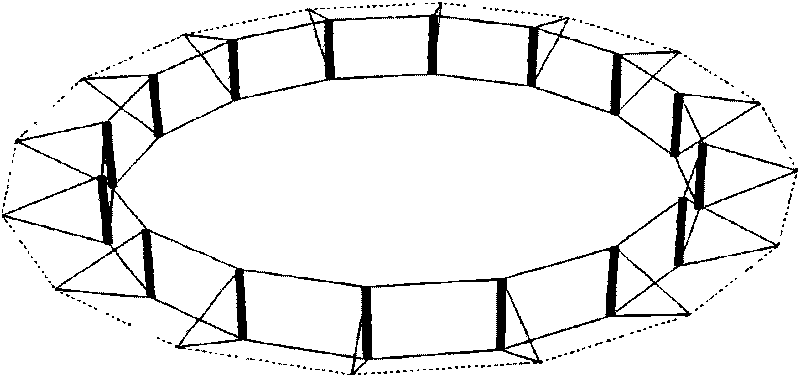

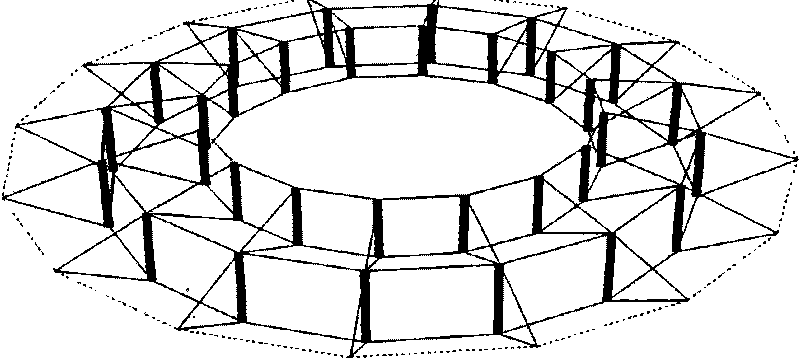

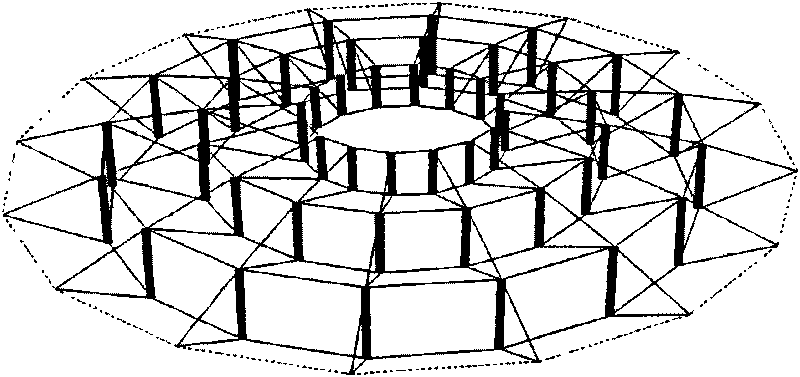

Layer-by-layer double-ring rib-ring type cable dome structure and construction forming method

A technology of cable dome and ring rib, which is applied in the field of layer-by-layer double ring rib ring cable dome structure and construction forming, can solve the problems that cannot be built well, can not be built, etc., achieve simple tensioning equipment and control methods, reduce construction costs, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] 1. Construction and production of cable-strut joints:

[0054] by Figure 4 The layer-by-layer double-ring rib ring cable dome structure shown is an example, and the components associated with the cable-strut nodes include upper and lower ring cables 1, 1', upper and lower inclined cables (rods) 2, 2', and struts 3 .

[0055] The manufacturing process of the upper cable rod node is as follows: Figure 5 a. Figure 5 b. Figure 5 c. Figure 5 d. Figure 5 e. Figure 5 f. Figure 5 g. Figure 12 , Figure 13 shown. Process an elliptical steel ring 4 by casting or cutting process; drill a bolt hole 5 on a narrow side of the elliptical steel ring 4; drill a round hole 6 in the middle of a wide side of the elliptical steel ring 4 until the other wide side; Be processed into screw hole 7 at the round hole 6 tops of a broadside of oval steel ring 4; Weld the lug plate 8 of oblique cable (rod) 2 on this layer at one end of a narrow side of oval steel ring 4; One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com