Steel-tube-sheet pile sunk-well foundation and steel-tube-sheet pile used thereof

A steel pipe and sheet pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as the inability to reduce the amount of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

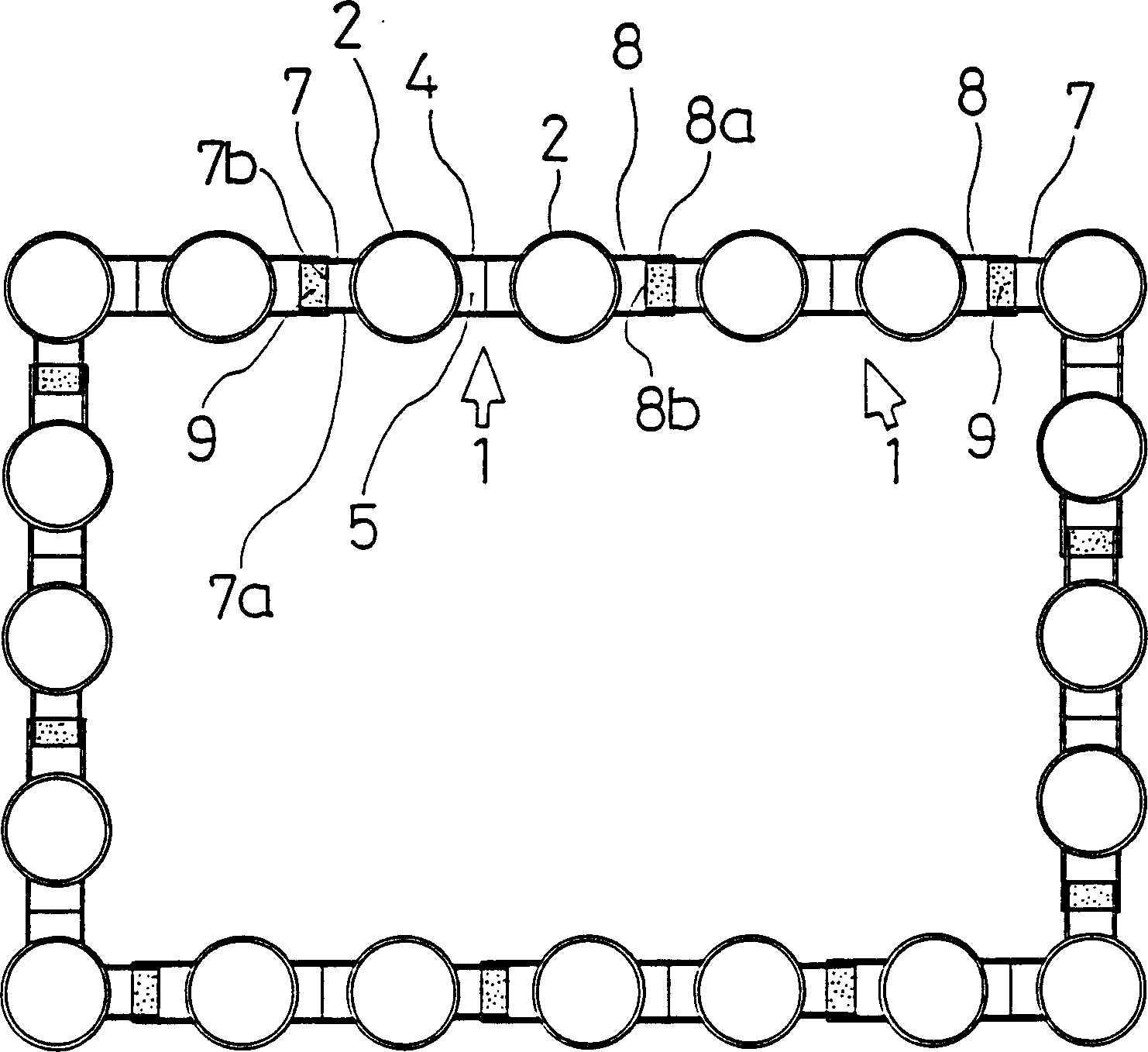

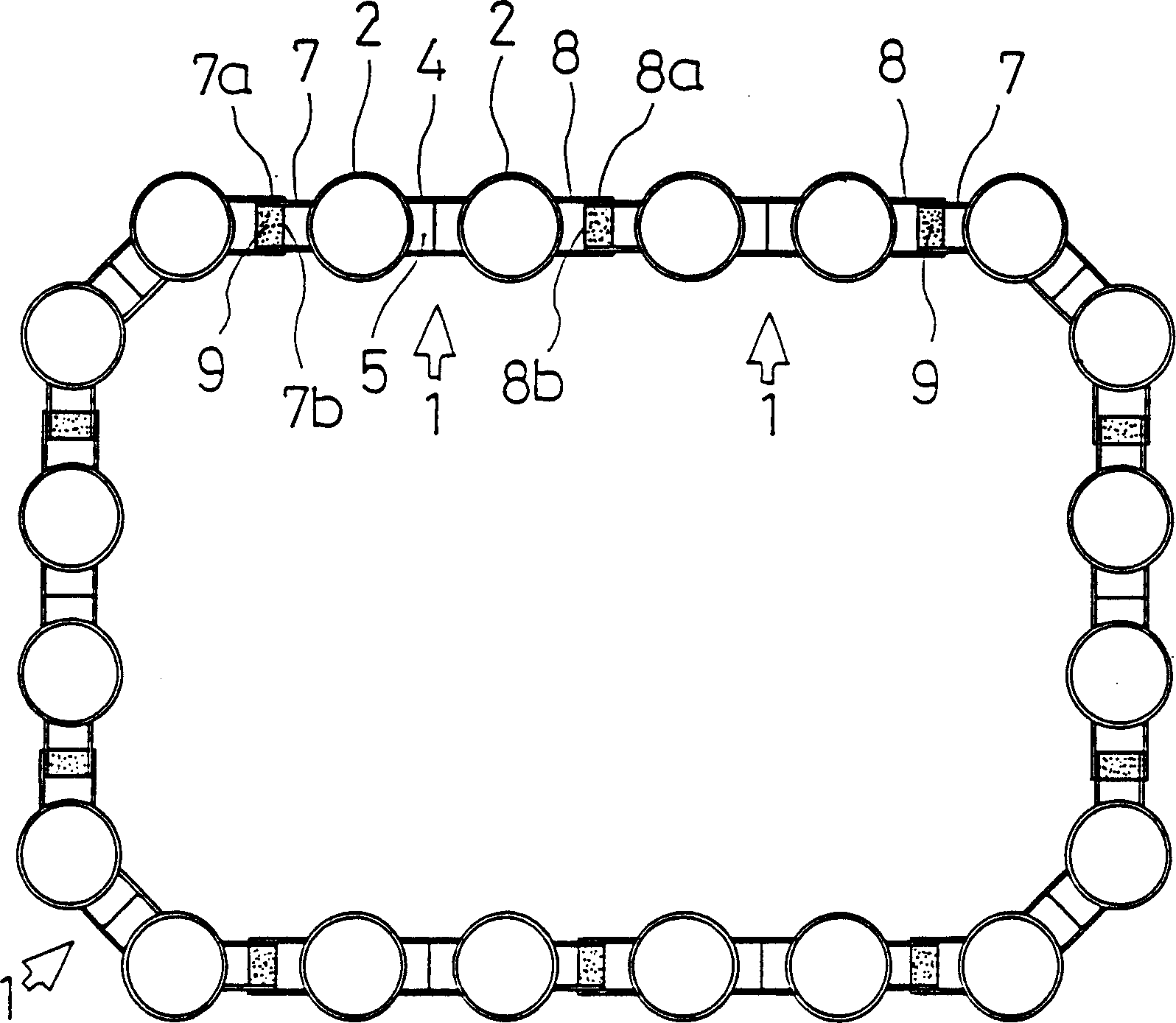

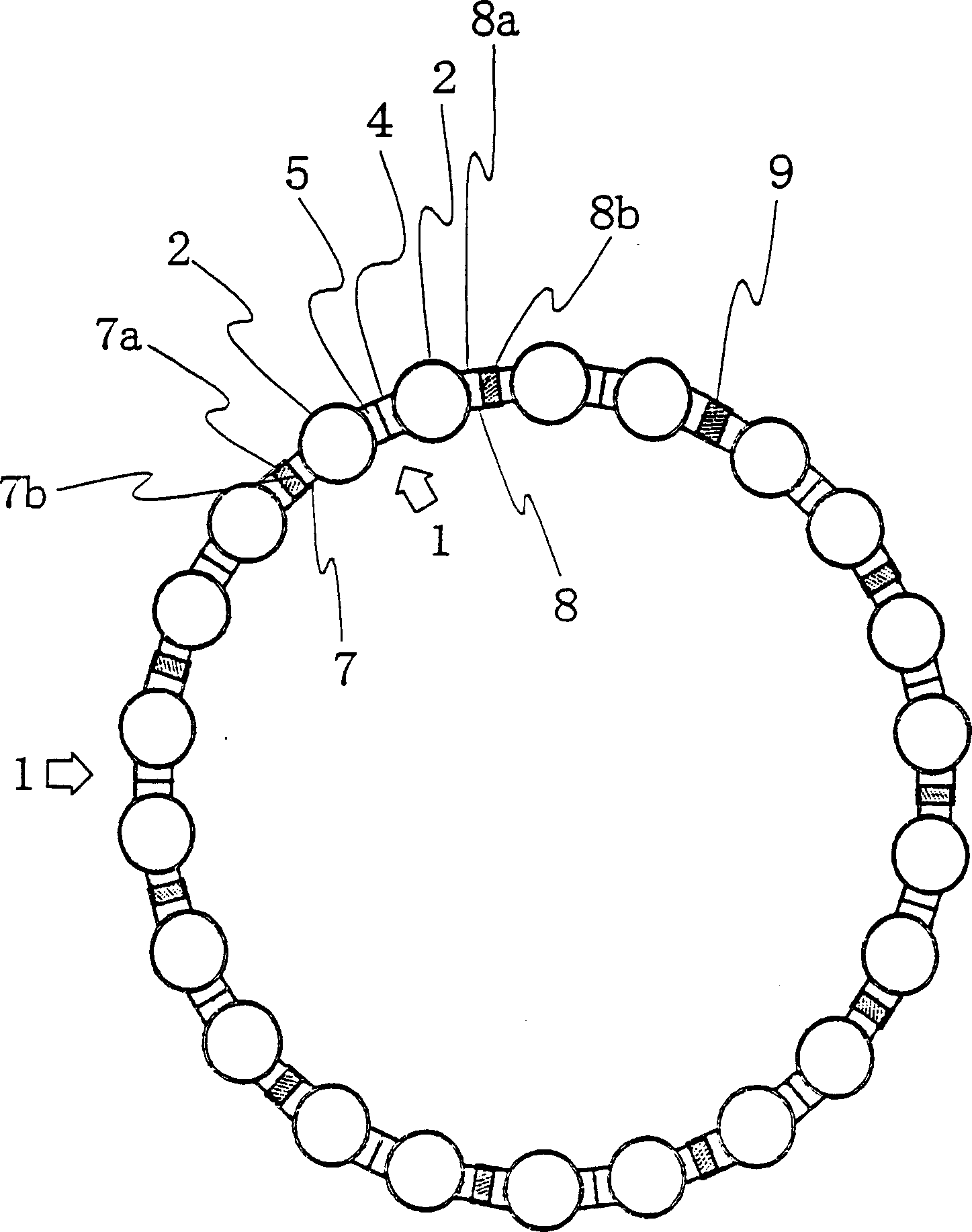

[0054] Embodiments of the present invention will be described in detail below with reference to the drawings. Figure 1 ~ Figure 3 It is a plan view of the first to third embodiments of the steel pipe sheet pile caisson foundation of the present invention. First, it will be described from one unit of the H-steel connection type steel pipe sheet pile used in the present invention, as follows: Figure 4 As shown, in the H-steel connection type steel pipe sheet pile 1, the H-shaped steel 4 is used as a tie rod member, which makes the steel pipes 2 arranged in parallel weld together with the flange edge at the periphery of each steel pipe 2, and only the H-shaped steel The width of 4 is welded integrally at intervals. In addition, an H steel external thread pipe joint 7 and an H steel internal thread pipe joint 8 are provided on the opposite side to the mutual welding.

[0055] The H-shaped steel 4 can be rolled from steel, and can also be assembled separately through appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com