Construction method of steel pipe arch bridge

A construction method and technology for steel pipe arch bridges, applied to arch bridges, bridges, bridge materials, etc., can solve the problems of long-term occupation of waterways, high construction costs, and inconvenient construction, and achieve the effects of fast erection, efficient and safe construction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

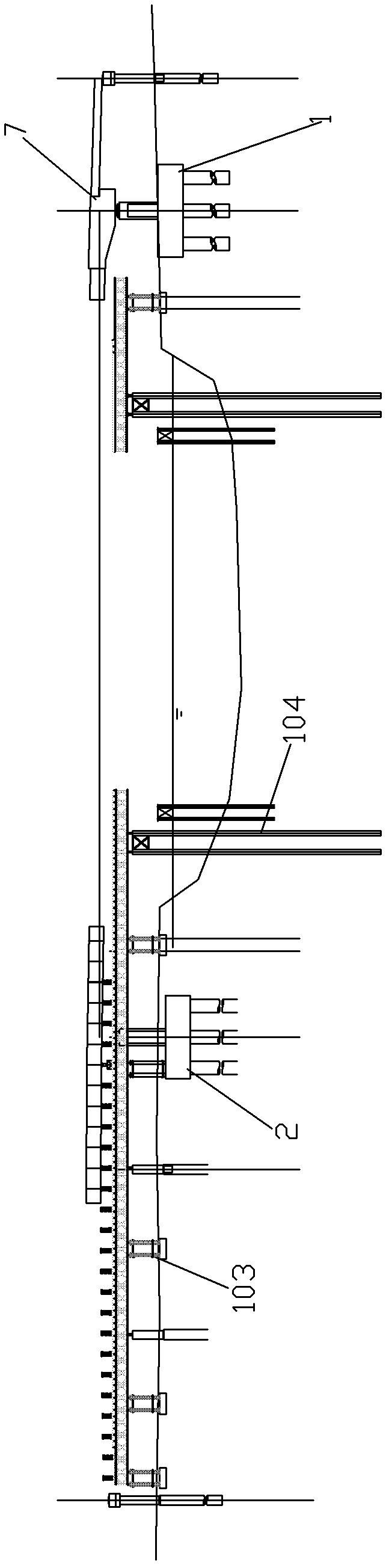

[0052] For a construction method of a steel pipe arch bridge, please refer to Figure 8 to Figure 16 ,it includes:

[0053] Step 1, constructing the first bridge pier 1 and the second bridge pier 2, and pouring the cast-in-place beam 7 on the first bridge pier 1; and, in this embodiment, the first approach bridge and the second approach bridge are also constructed, and the first approach bridge is connected The first pier, the second approach bridge connects to the second pier;

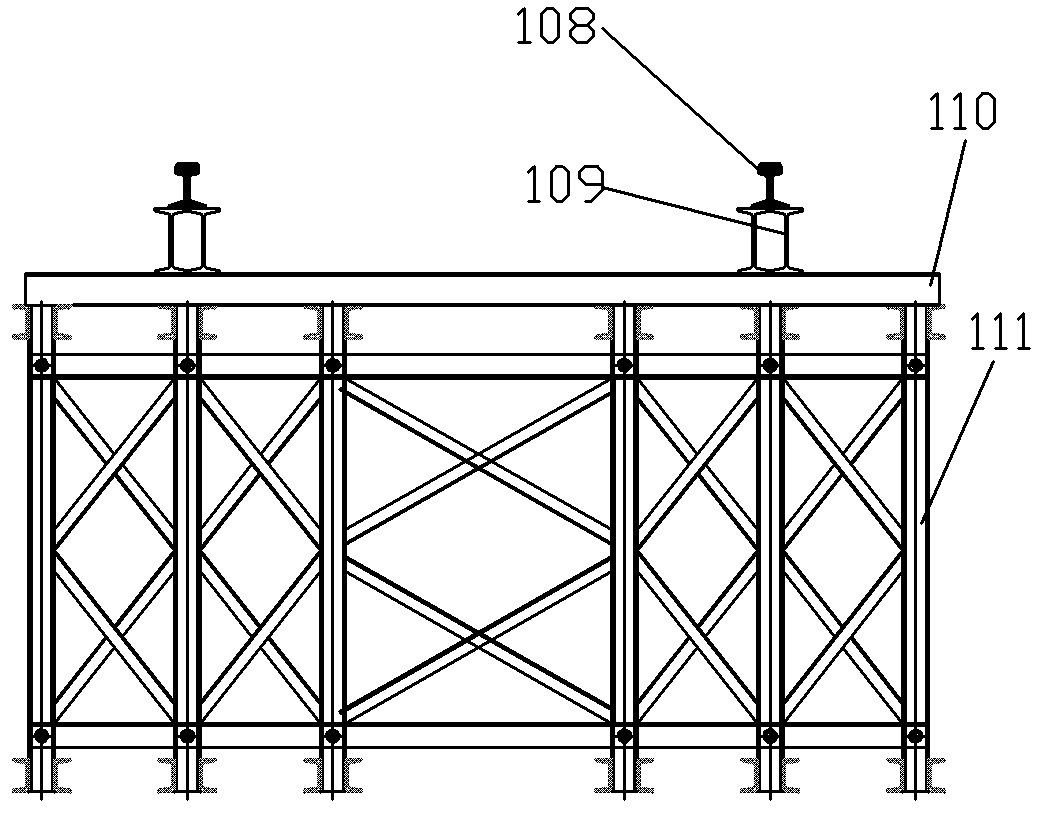

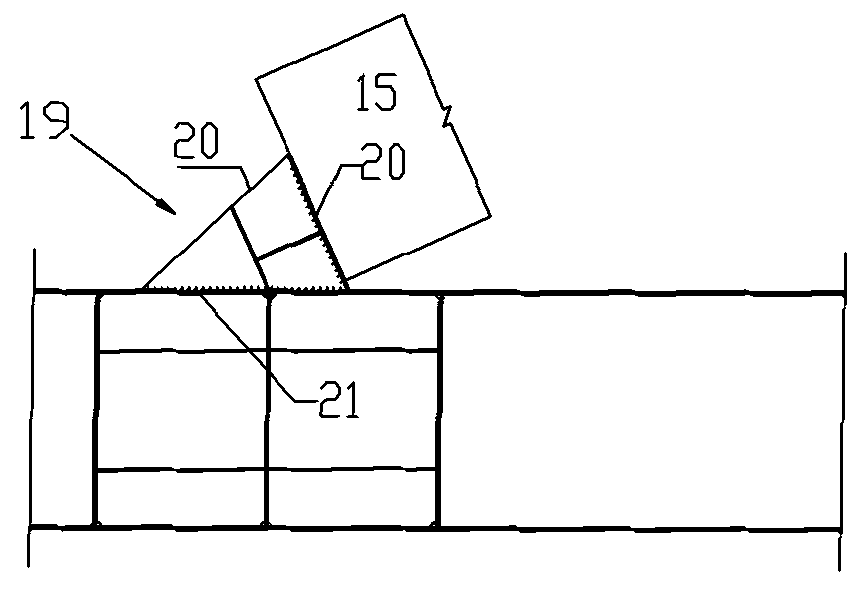

[0054] Step 2, on the side corresponding to the second pier 2, such as the second approach bridge, fix and assemble multiple sections of steel girders into a steel girder intermediate section 5, and assemble multiple sections of arch tubes into an arch tube intermediate section 15 on the second pier 2, The middle section of the steel beam 5 and the middle section of the arch tube 15 are combined to form the middle section of the arch beam 22, and the middle section of the arch tube 15 is located abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com