Single-layer latticed shell structure with drum type nodes, and assembly method

A single-layer reticulated shell and assembly method technology, applied in the field of steel structure, can solve the problems of complex structure and poor assembly performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

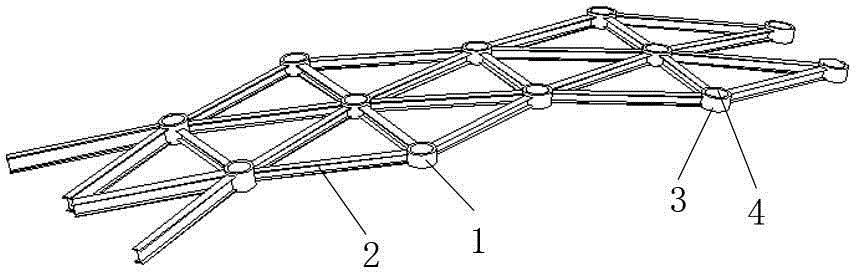

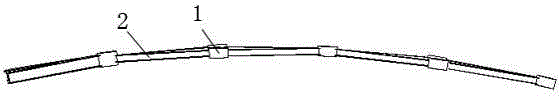

[0079] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, a drum-shaped node single-layer reticulated shell structure includes more than two sets of honeycomb components assembled together. The described honeycomb components include 7 drum-shaped nodes 1 and web bars 8, of which 6 Two drum-shaped nodes 1 form a hexagonal shape, and another drum-shaped node 1 is located in the middle of the six drum-shaped nodes 1 , and the drum-shaped nodes 1 are connected and positioned through web bars 2 .

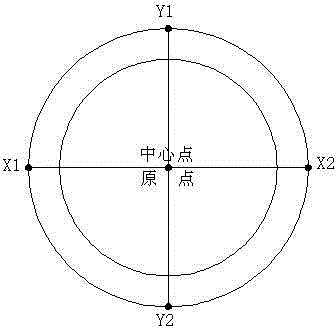

[0080] The cross-sections of the honeycomb components assembled by the two groups are distributed in an arc shape. The drum-shaped nodes include round tubes 3, and the upper and lower parts of the round tubes 3 are respectively provided with embedded sealing plates 4. The web 2 is H-shaped steel, and the drum-shaped node 1 and the web 2 are welded and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com