Integral synchronous rotary jacking construction method for small radius horizontal curved bridge

A technology of synchronous rotation and construction method, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complicated synchronous rotation jacking process, and achieve the effect of reducing construction difficulty, speeding up construction progress, and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

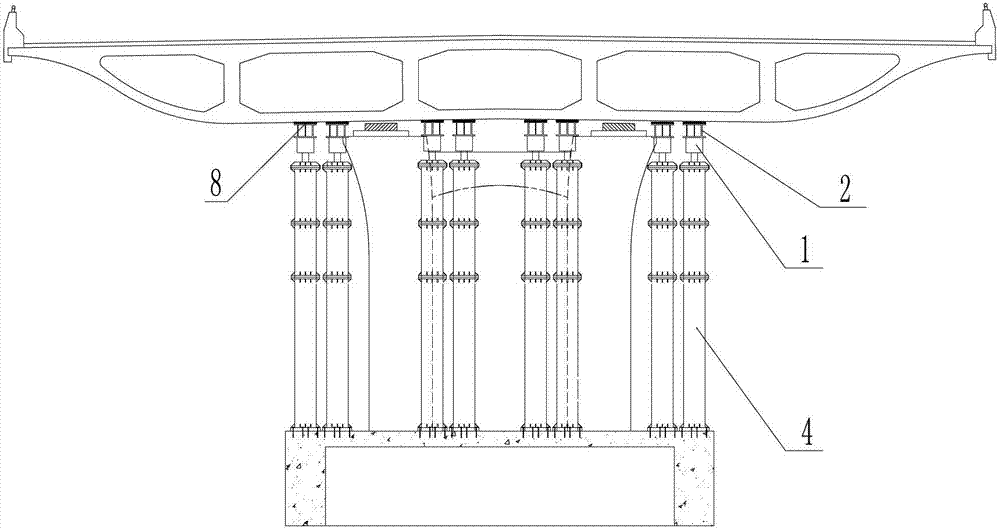

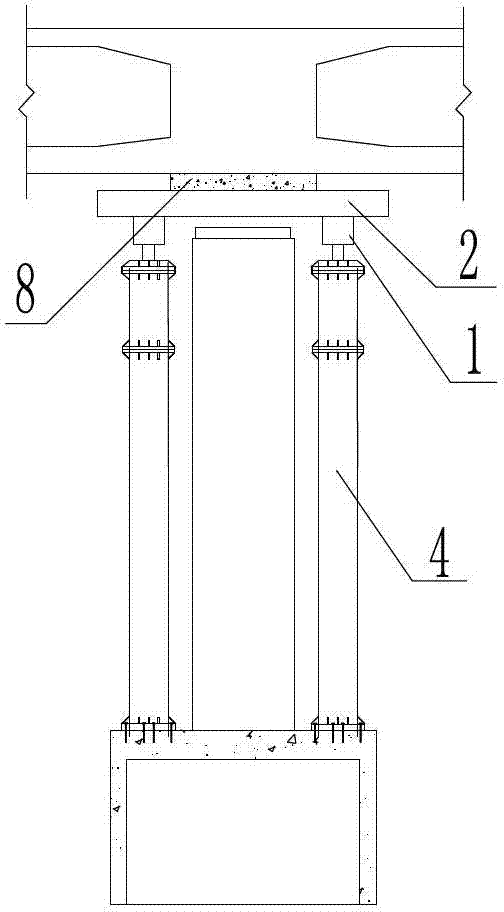

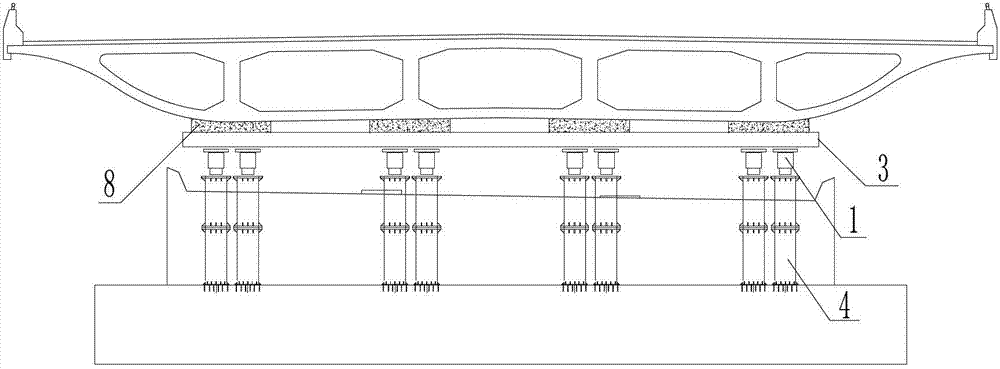

[0060] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0061] The present invention is aimed at small-radius flat-curve bridges. The horizontal projection of the main girder will elongate during the overall synchronous rotation and jacking process, which means that the end of the main girder moves out of the bridge, and at the same time, it is accompanied by the displacement of the transverse bridge. The more critical It is because the jacking displacement of the main girder in the direction of the transverse bridge is not consistent during the rotating jacking process. During the jacking process, it is necessary to control the rotation of the small-radius horizontal curve bridge along the central axis of the main girder (the difference in the jacking displacement of the horizontal bridge), and at the same time pay attention to the longitudinal slip and lateral swing of the main girder to prevent the beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com