Orthotropic steel plate-concrete composite bridge deck and construction method thereof

An orthotropic and concrete technology, applied in bridges, bridge construction, bridge parts, etc., can solve unfavorable problems, achieve the effect of reducing the structure's self-weight, reducing the cost, and increasing the bending capacity of the transverse bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

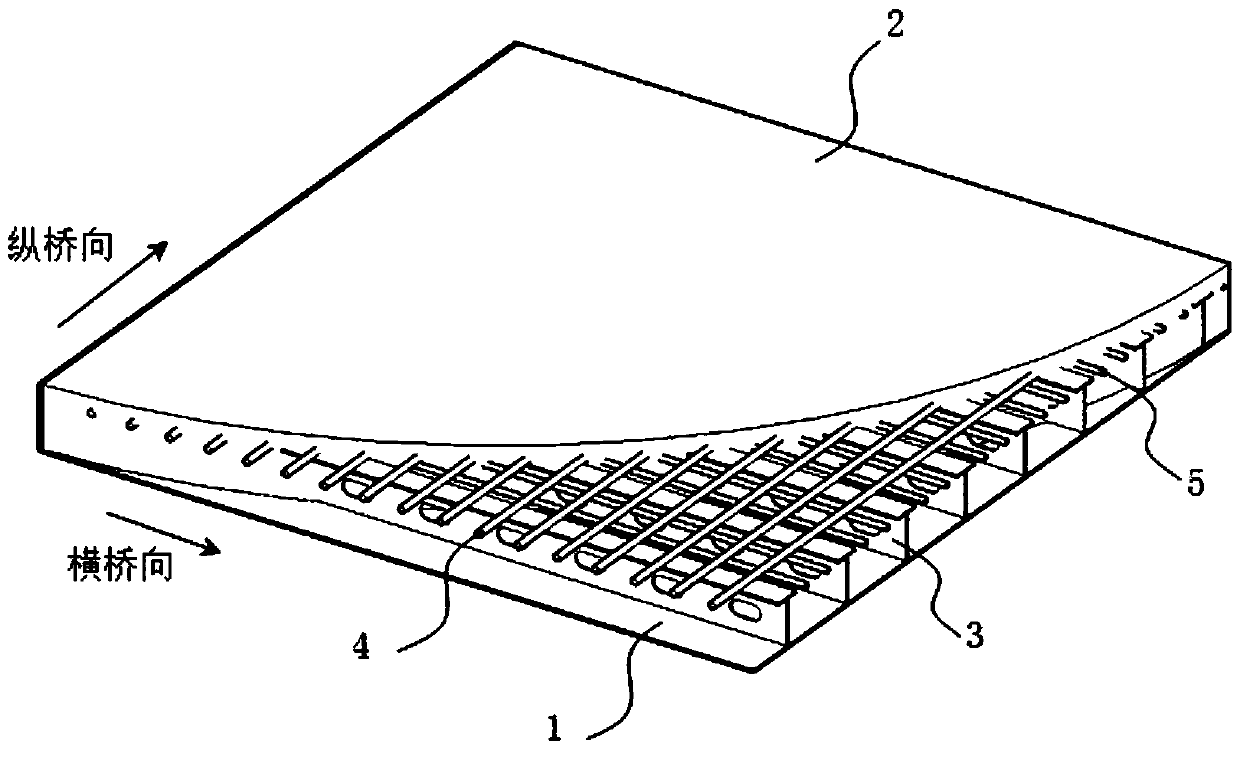

[0032] An orthotropic steel plate-concrete composite bridge deck is characterized in that it comprises an orthotropic steel plate, a reinforcement mesh and a concrete structure layer 2 .

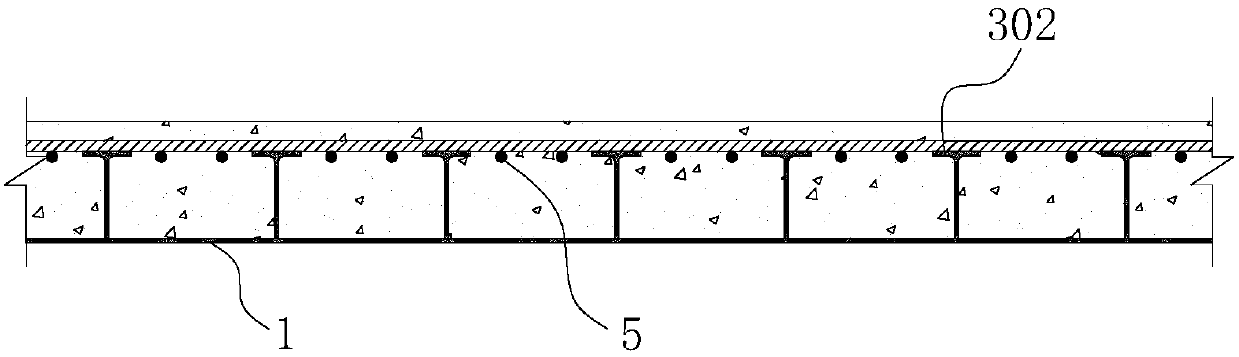

[0033] see figure 1 , the orthotropic steel plate includes a steel bottom plate 1 and eight T-shaped steel plates 3 . Each T-shaped steel 3 includes a T-shaped steel web 301 and a T-shaped steel flange 302 . The plate surfaces of the T-shaped steel web 301 and the T-shaped steel flange 302 are perpendicular to each other. The length direction of the T-shaped steel web 301 and the T-shaped steel flange 302 is consistent with the direction of the transverse bridge.

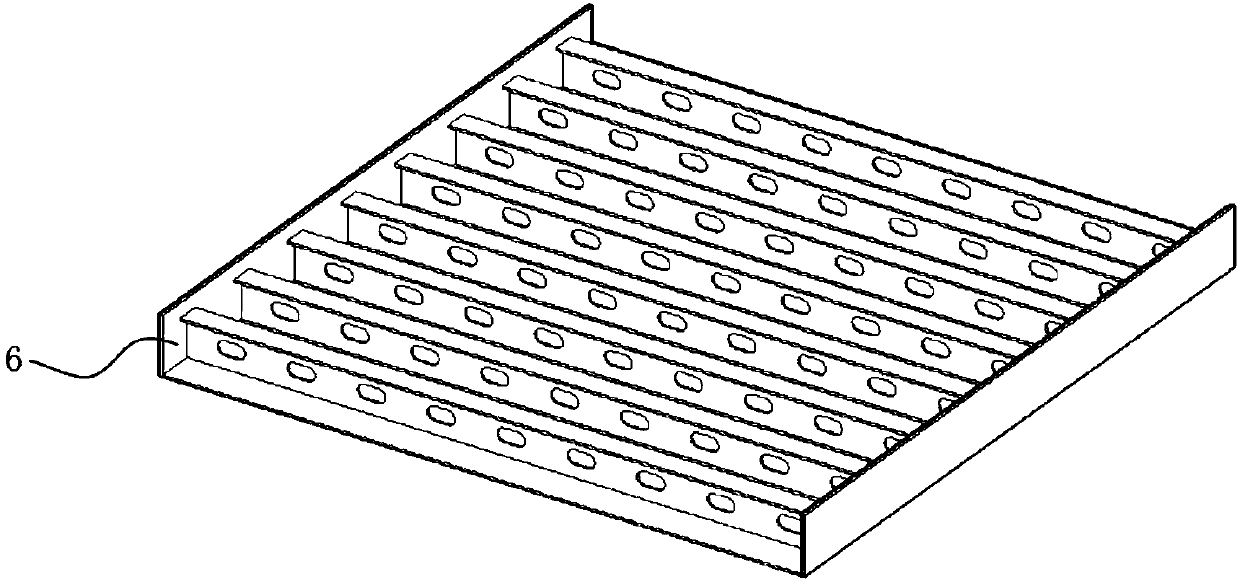

[0034] see figure 2 and image 3 , the eight T-shaped steels 3 are arranged at intervals along the longitudinal bridge direction on the upper surface of the steel base plate 1 . The steel bottom plate 1 is parallel to the surface of the T-shaped steel flange 302 and perpendicular to the surface of the T-shaped steel web 301 ...

Embodiment 2

[0041] This embodiment discloses a construction method for the orthotropic steel plate-concrete composite bridge deck described in Embodiment 1, which includes the following steps:

[0042]1) Orthotropic steel plates are processed in a factory. Widened circular holes 3011 are provided at intervals in the T-shaped steel web 301 . T-shaped steel 3 and flange baffle 6 are welded on the upper surface of steel base plate 1 .

[0043] 2) Transport the processed orthotropic steel plate to the construction site. The orthotropic steel plate is hoisted to the steel longitudinal beam by a crane, and its position is precisely adjusted. After the position adjustment is completed, the orthotropic steel plate is welded to the steel longitudinal beam.

[0044] 3) Make reinforcement mesh at the reinforcement processing factory near the bridge site. After the processed steel mesh is transported to the construction site, the steel mesh sheet is hoisted and laid above the T-shaped steel flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com