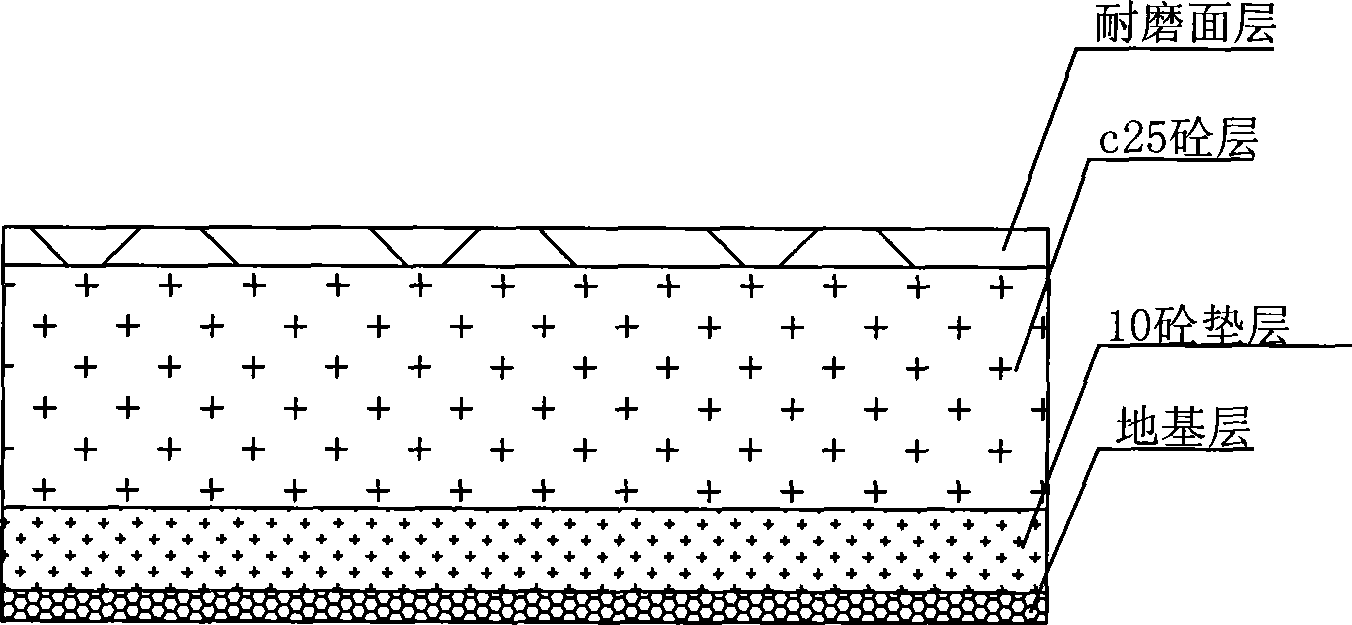

Method for controlling flatness and elevation of large area wear resistant terrace

A control method and flatness technology, which is applied in the processing of floors, building materials, construction, etc., can solve the problems of low flatness and elevation control accuracy, and difficulty in meeting flatness control standards, and achieve high construction accuracy, Convenient construction and high leveling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

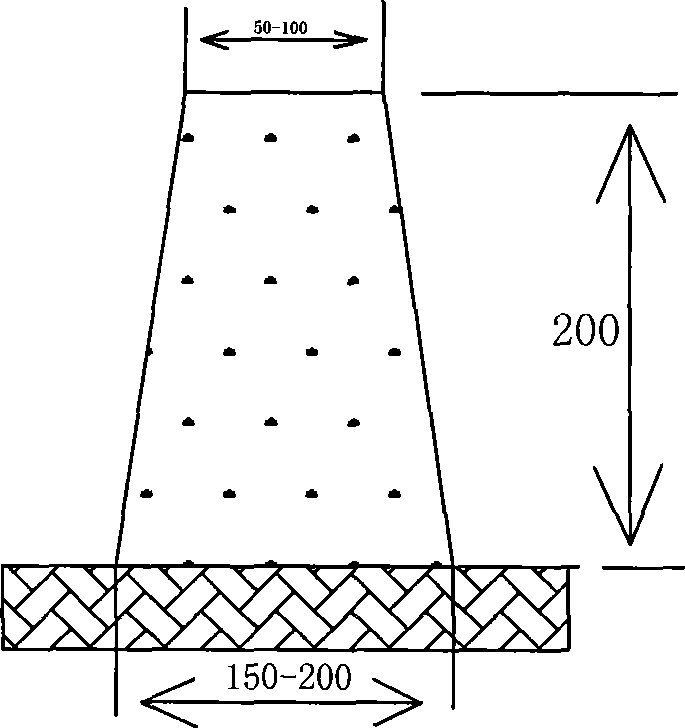

[0043] Embodiment one, such as image 3 ,Such as Figure 4 As shown, a certain floor of the concrete cushion 17 has been prepared according to the "railway" laying method, and the position of the hole on the concrete cushion 17 is determined. The hole spacing on the angle iron 12 is 1900mm. Therefore, the concrete pad 17 is also dimensioned according to this.

Embodiment 2

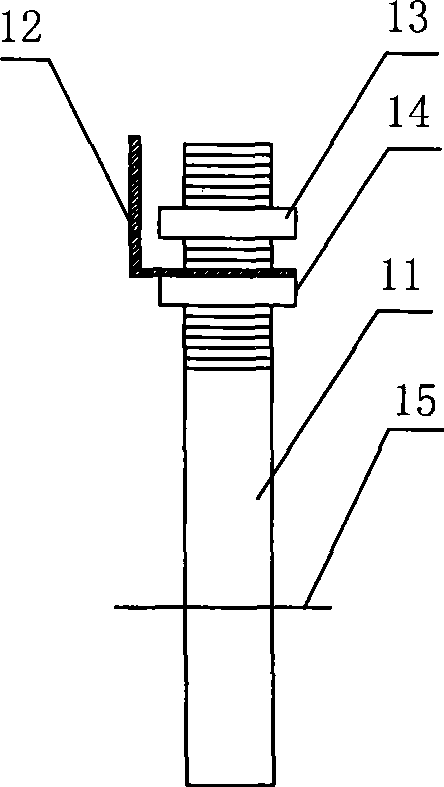

[0044] Embodiment two, such as image 3 Figure 4 and Figure 5 As shown, a drill bit with a diameter of 12mm is used to drill holes according to the lofting position, and then the unthreaded end of the bolt 11 with a diameter of 14mm and welded with a supporting steel bar 15 is nailed into the concrete cushion 17. If the bolt 11 and the concrete cushion If there is looseness between the holes on the 17, nail it into the holes on the concrete cushion 17 for reinforcement, then screw the adjusting nut 14 on the threaded end of the bolt 11, and then screw 12 sets of angle irons that are punched. On the bolt 11, the fixing nut 13 is screwed on the bolt 11 at last. At this time, two angle irons 12 that are 6m long and have holes drilled according to the spacing of 1900mm in advance are placed on each bolt 11 that is nailed in after lofting. The angle iron 12 big samples of " rail formula " at that time just make and place and finish.

Embodiment 3

[0045] Embodiment three, such as image 3 , Figure 4 and Figure 5 As shown, a level is used to level the angle iron 12, and the surveyor uses the level to level the angle iron 12. The construction personnel lift and adjust the nut 14 according to the surveyor's instructions, and adjust the height of the angle iron 12 (the adjustment must be made for each bolt. 11 should be well prepared), so that each angle iron 12 is on the same horizontal plane. Generally, the laying of "railway type" angle iron 12 is set to 5m between two angle irons 12, so that the 6m ruler can be used for leveling Two angle irons 12 are on the same horizontal plane, and at this moment, the elevation point is just checked and passed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com