Integral setting and one-step in-position construction method for steel sleeves of inner pipelines of vertical shaft of building

A construction method and technology of pipeline steel, which are applied in the construction, building structure, processing of building materials, etc., can solve the problem of a one-time construction method without the overall shaping of the pipeline steel casing in the building shaft, and improve the construction quality. And the effect of improving work efficiency, construction accuracy and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

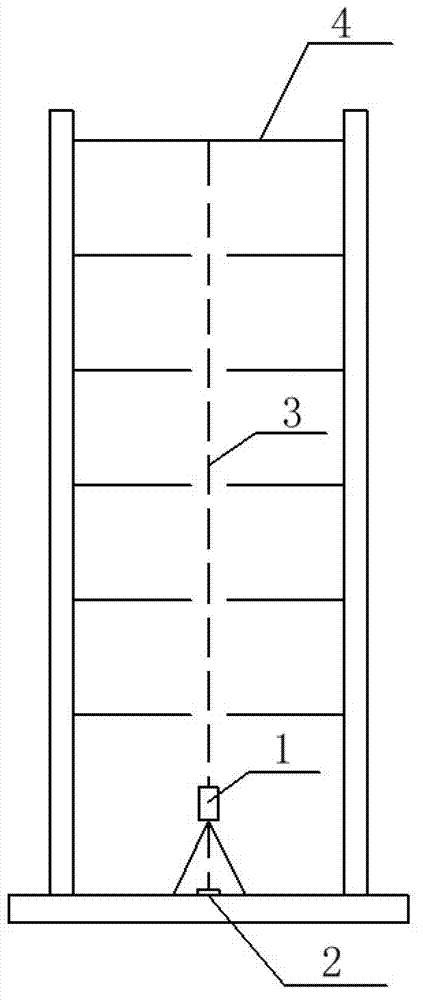

[0031] A construction method for one-time in-place construction of pipeline steel casings in building shafts, which is carried out according to the following steps:

[0032] (1) In the construction preparation stage, analyze and study the construction drawings, clarify the number, pipe diameter and size of the casing used for each pipe riser in the shaft, and consider the overall thickness of the wall, the stucco layer, and the position of the bracket On the basis of the valve size and pipeline maintenance factors, the scientific positioning data of the distance between the casing and the wall and the mutual distance are formed, and then simulated on the computer, and then the overall installation plane positioning diagram of the casing group is formed;

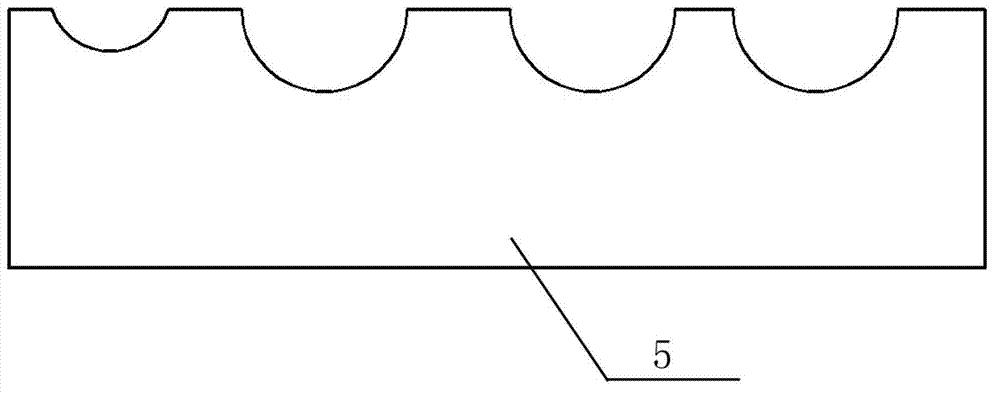

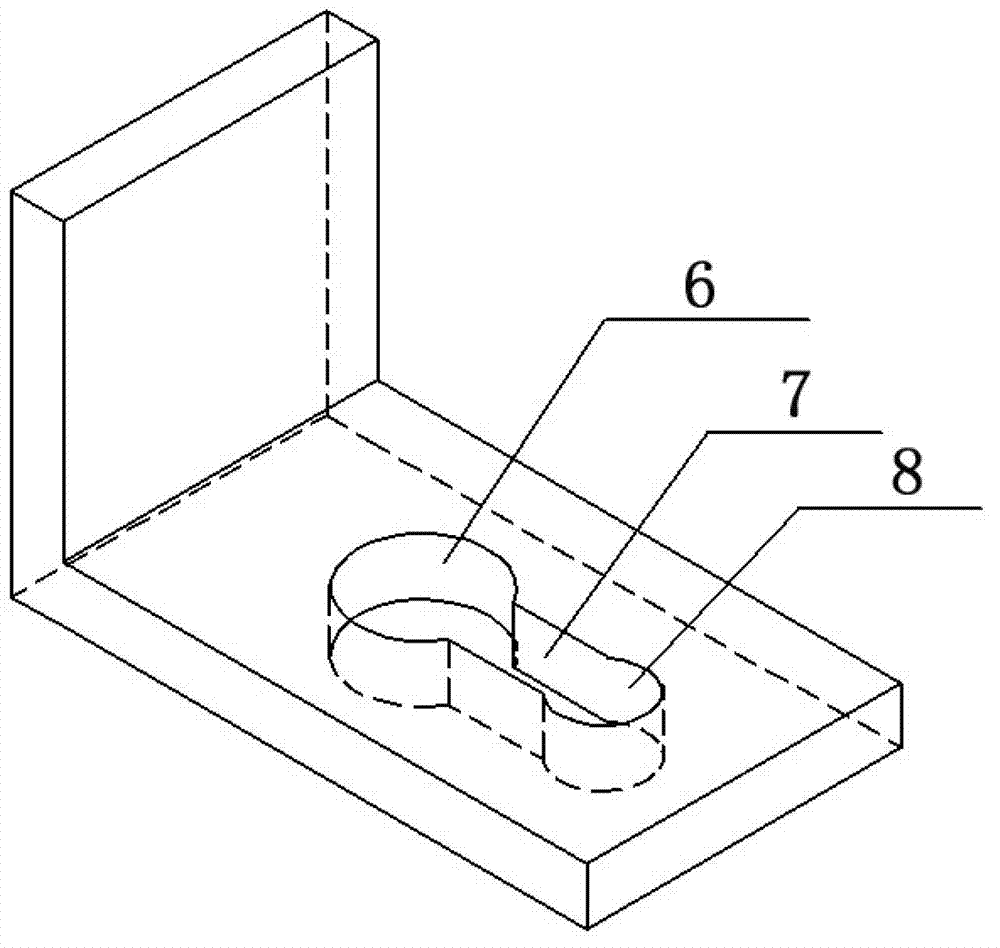

[0033] (2) According to the positioning dimensions of the overall installation plane of the casing, make the overall positioning mold 5 of the casing group with thin wood or other hard plates;

[0034] (3) With the aid of the...

Embodiment 2

[0044]A construction method for one-time in-place construction of pipeline steel casings in building shafts, which is carried out according to the following steps:

[0045] (1) In the construction preparation stage, analyze and study the construction drawings, clarify the number, pipe diameter and size of the casing used for each pipe riser in the shaft, and consider the overall thickness of the wall, the stucco layer, and the position of the bracket On the basis of the valve size and pipeline maintenance factors, the scientific positioning data of the distance between the casing and the wall and the mutual distance are formed, and then simulated on the computer, and then the overall installation plane positioning diagram of the casing group is formed;

[0046] (2) According to the positioning dimensions of the overall installation plane of the casing, make the overall positioning mold 5 of the casing group with thin wood or other hard plates;

[0047] (3) With the aid of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com