Test unit of variable-pitch system of wind generation set

A technology of pitch control system and test device, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. The effect of flexible load adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

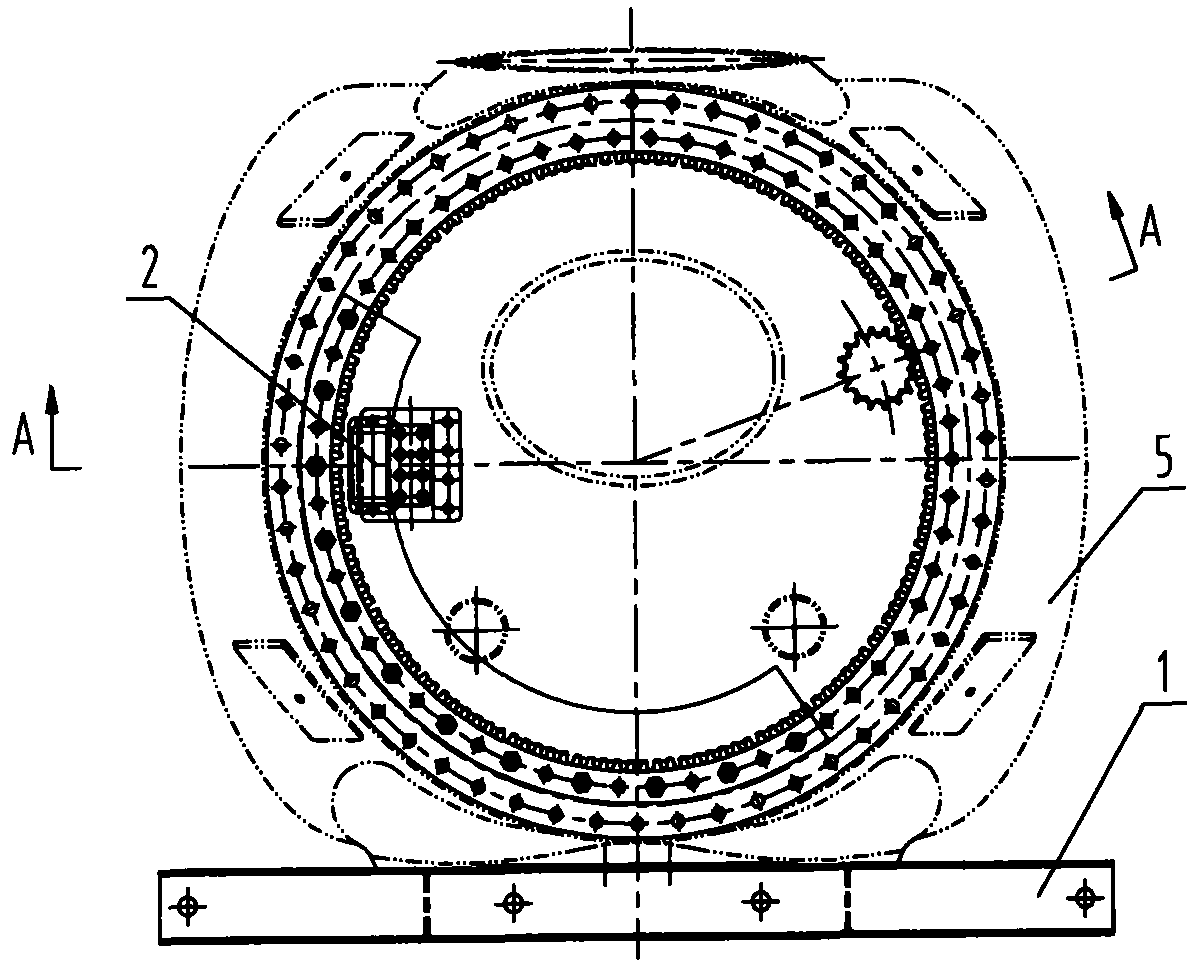

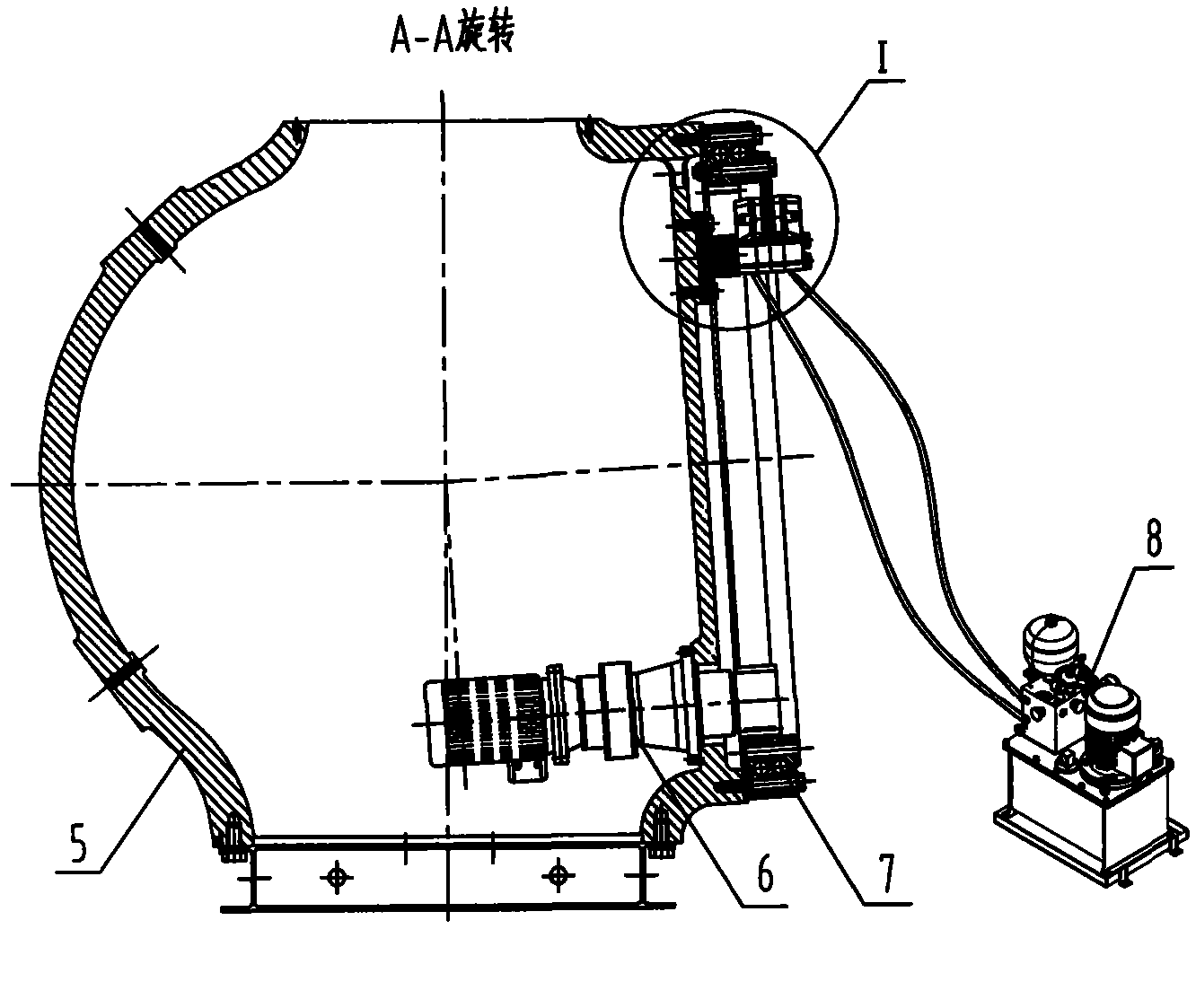

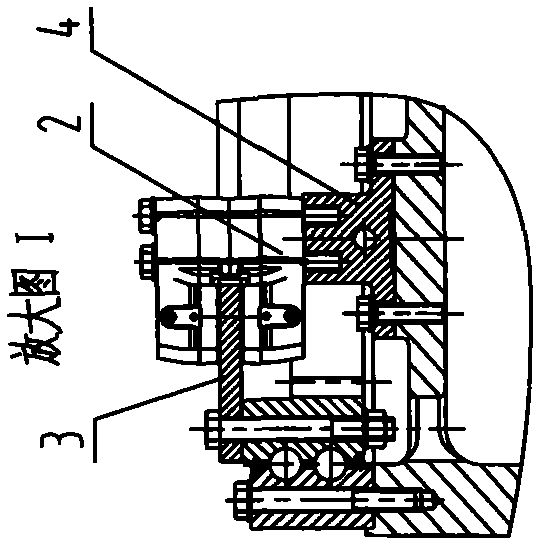

[0013] like figure 1 , 2 , 3, a test device for the pitch system of a wind turbine, comprising: a hub 5 and a pitch drive assembly 6 and a pitch bearing 7 mounted thereon, the pitch drive assembly 6 driven by the The inner ring of the pitch bearing 7 is connected to the brake disc 3 , the brake 2 is connected to the hub 5 through the mounting seat 4 , and the brake 2 is connected to the hydraulic station 8 .

[0014] The tooling frame 1 is used as a support, the upper part is connected with the wheel hub 5, and the lower part is connected with the ground beam of the factory building; the brake disc 3 is connected with the inner ring of the pitch bearing through bolts; the hydraulic station 8 is used as a power source to load the brake disc 3 through the brake 2, By changing the pressure of the hydraulic station, different frictional moments can be formed on the brake disc, thereby simulating different pitch and pitch torsional loads.

[0015] Working process of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com