A special adapter and fixing device for 10-ton planetary roller screw loading test

A planetary roller, loading test technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as damage to angular contact ball bearings, achieve high reliability, simplify operating procedures, and reduce quantity little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

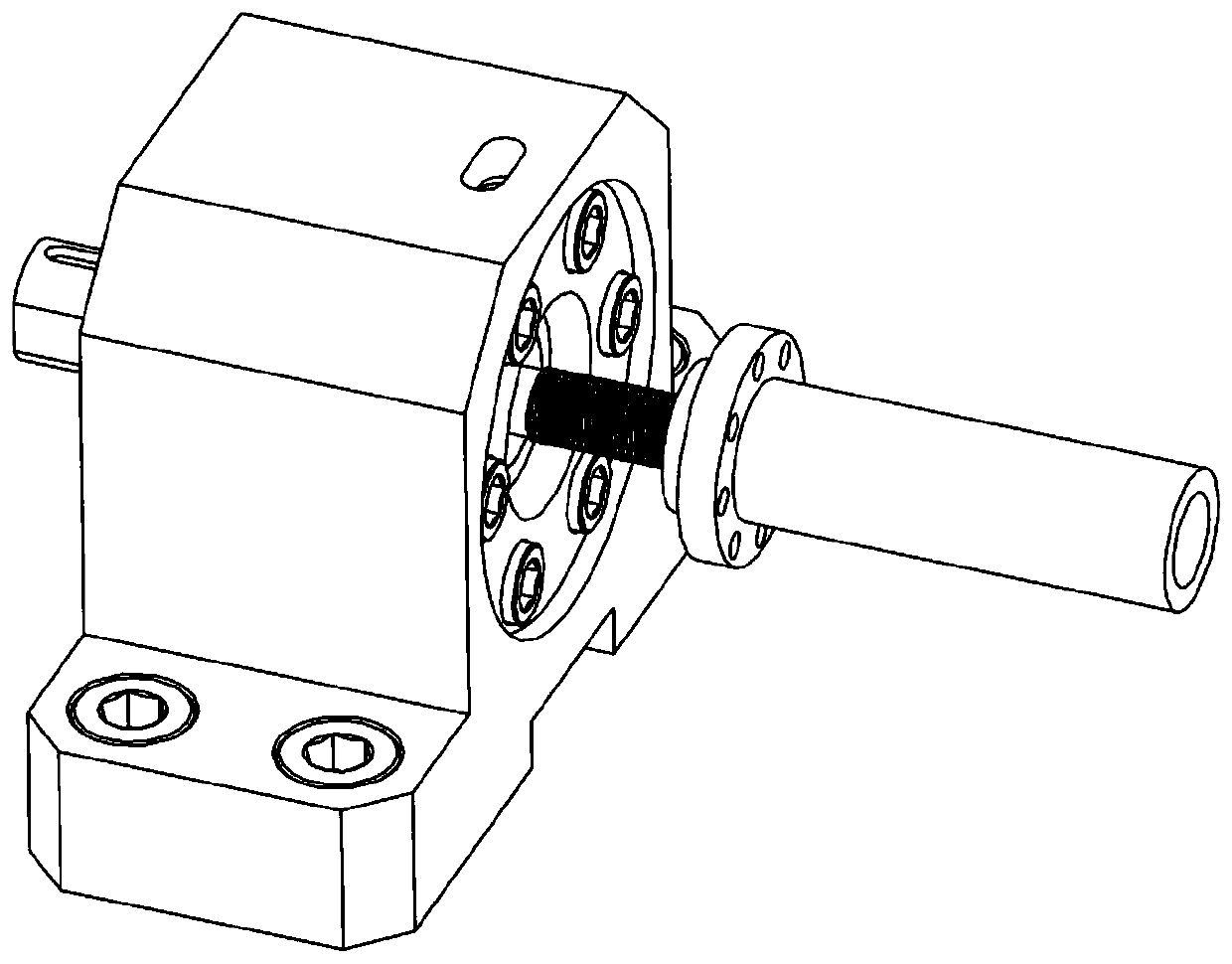

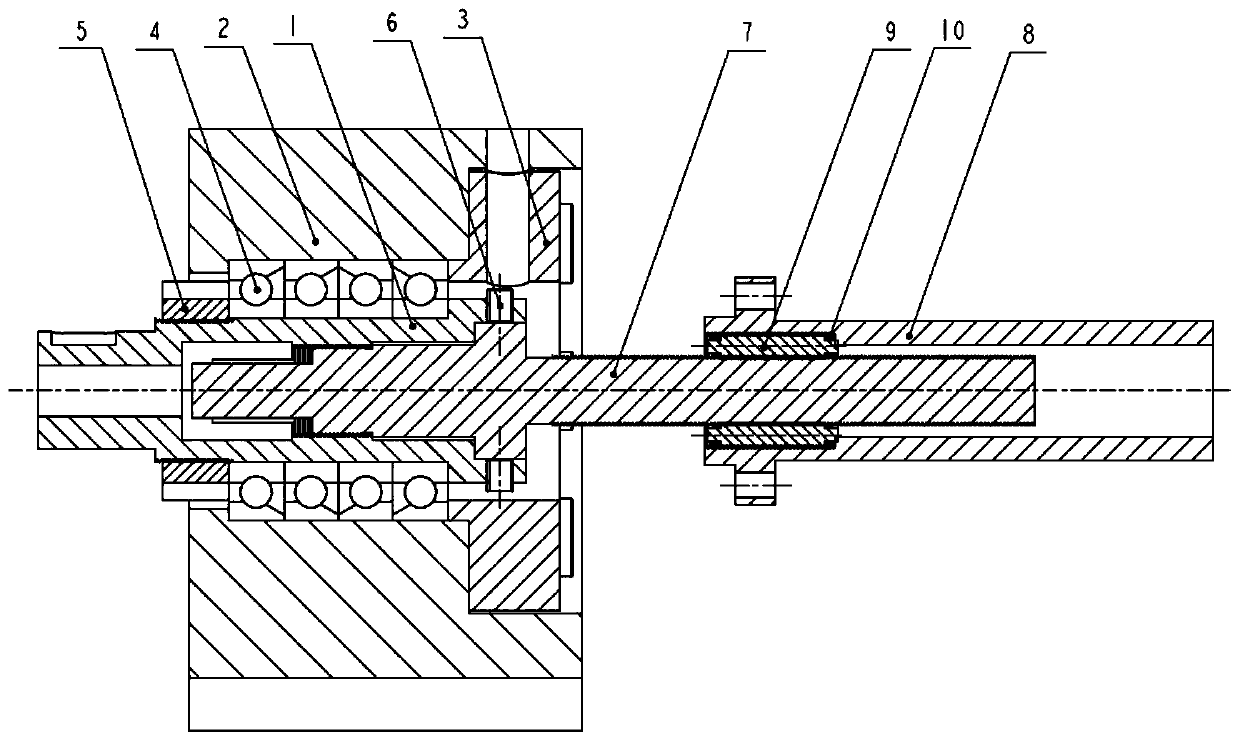

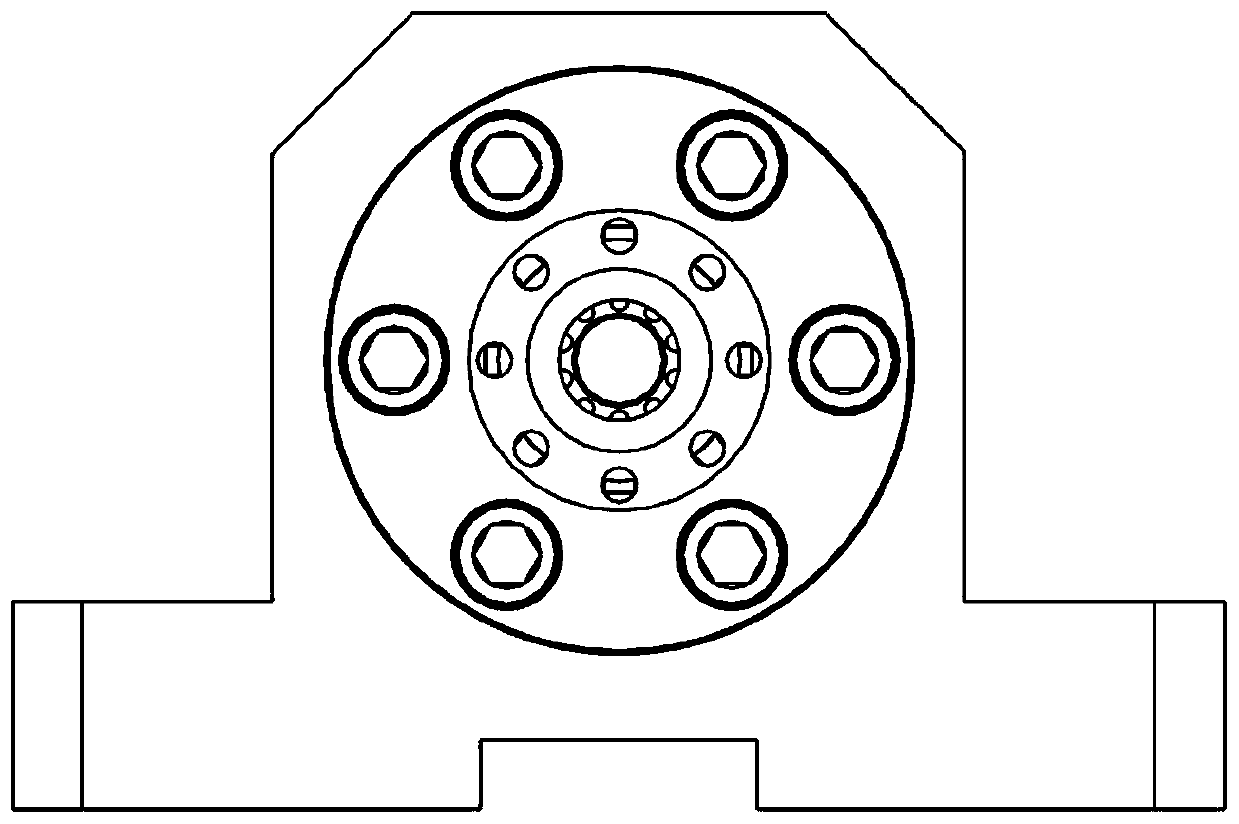

[0020] Such as Figure 1 ~ Figure 3 As shown, it is a schematic diagram of the external and internal structure of the present invention, a 10-ton planetary roller screw screw loading test special adapter and fixing device, including: screw pair adapter sleeve 1, four-row bearing fixed support 2 , Bearing fixed end cover 3, angular contact ball bearing 4, sleeve lock nut 5, sleeve anti-roll screw 6.

[0021] The 10-ton planetary roller screw pair includes a screw rod 7, a screw nut 8, a roller 9, and a cage 10. The lead screw nut 8 is set on the lead screw 7, the rollers 9 are distributed along the circumference of the lead screw 7, and are installed between the lead screw 7 and the lead screw nut 8 through the cages 10 at both ends, and the lead screw nut 8 passes through the rollers. The column 9 realizes the movement on the lead screw 7 .

[0022] Such as figure 2 As shown, the interconnection relationship of each part of the present invention is as follows: the lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com