Large-tonnage pile foundation test loading device

A loading device and large tonnage technology, which is applied in the testing of foundation structures, sheet pile walls, transportation and packaging, etc., can solve the problems affecting the loading test efficiency of test piles, many connection steps between anchor piles and test piles, and poor flexibility of anchor piles, etc. problem, to achieve the effect of stable movement, improved flexibility, and convenient analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

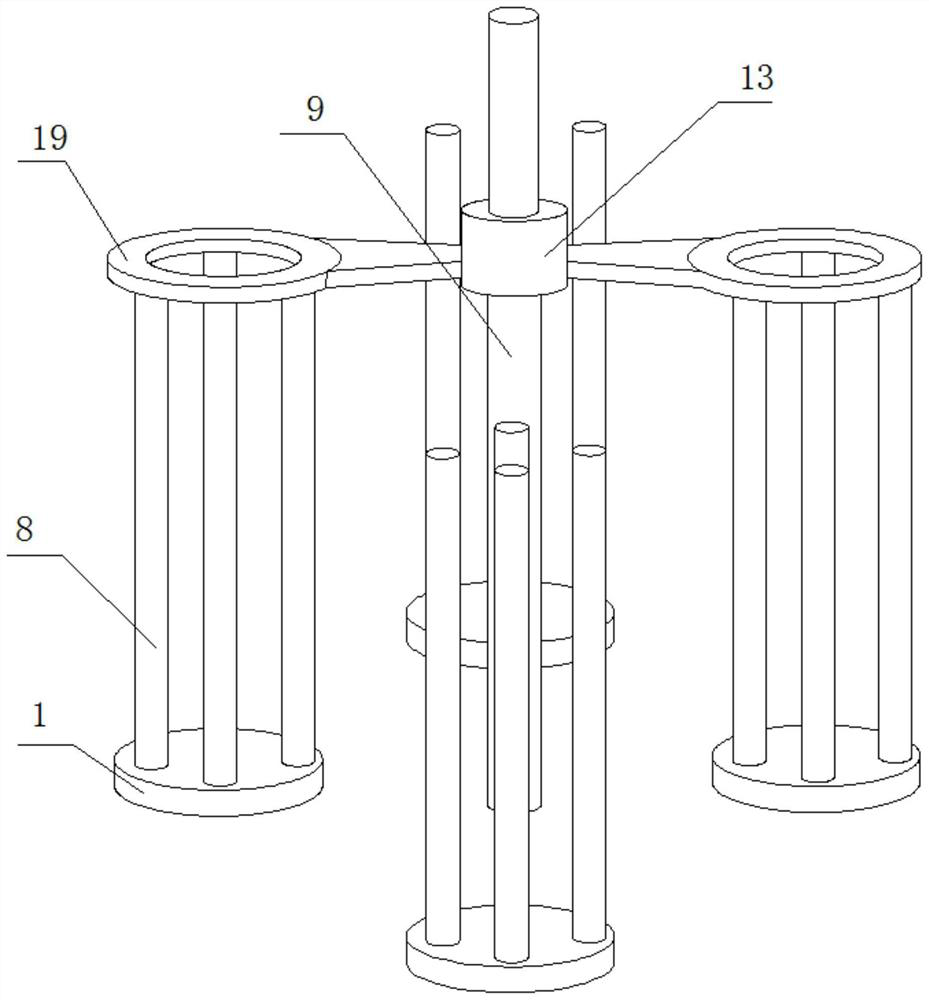

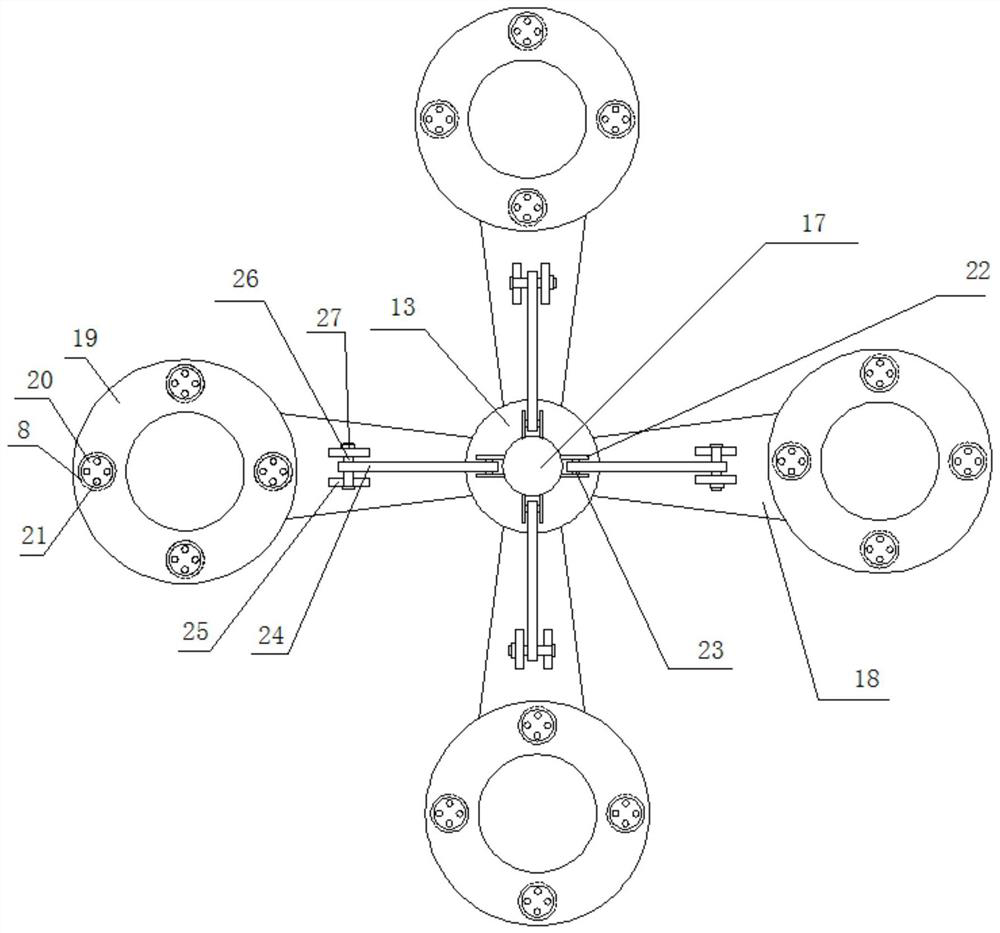

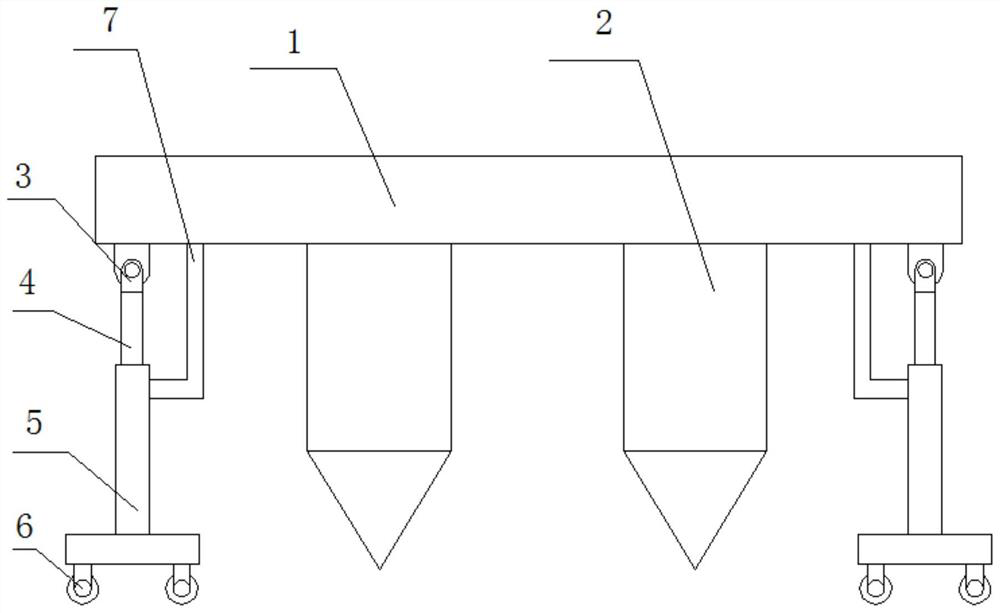

[0028] Such as Figure 1-5 A large-tonnage pile foundation test loading device is shown, which includes four disc bases 1 arranged equidistantly in a ring, four anchor rods 2 arranged in a matrix are fixedly installed on the bottom of the disc base 1, and four The bottoms of the anchor rods 2 are tapered, and the bottom of the disc base 1 is provided with a moving assembly. The moving assembly includes two rotating seats 3 fixedly installed on the bottom of the disc base 1, and one side of the two rotating seats 3 rotates. A hydraulic cylinder 4 is installed, and a T-shaped plate 5 is fixedly installed on the bottom of the two hydraulic cylinders 4. A plurality of brake wheels 6 arranged in a matrix are fixedly installed on the bottom of the T-shaped plate 5, and the bottom of the disc base 1 is fixedly installed. There are two L-shaped limit plates 7 symmetrically arranged, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com