Robot simulation load test method, electronic equipment, device and system

A technology for simulating loads and testing methods, applied in the field of robotics, can solve the problems of ignoring the servo driver test, ignoring whether the servo driver matches the servo motor, ignoring whether the servo motor matches the robot, etc., to shorten the research and development cycle, save research and development costs, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

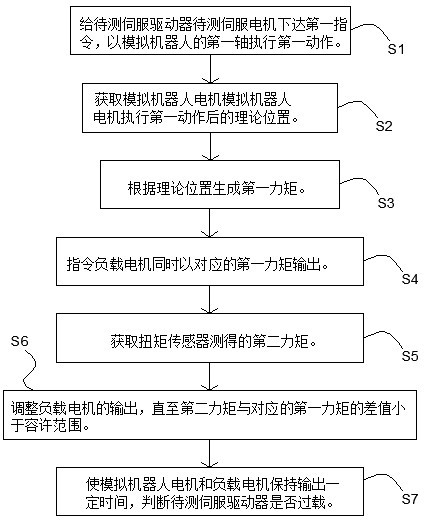

[0056] A robot simulation load testing method, which is carried out with a set of towing test bench, the towing test bench includes a simulated robot motor 13, a torque sensor 12 and a load motor 11 sequentially connected on the same axis, a servo drive 14 to be tested and a simulated robot Motor 13 is electrically connected, such as figure 2 As shown, the robot simulation load testing method includes the following steps:

[0057] S1: giving a first instruction to the servo driver 14 to be tested, so as to simulate the first axis of the robot to execute the first action. The first action refers to the simulated robot grabbing an object of a certain weight at a certain position and moving to another position. For example, the weight of the target object, the position before the robot moves, and the position where the robot will move are input in the industrial computer 18 used in the test. In fact, during the test, the simulated robot motor 13 is always on the towing test pl...

Embodiment 2

[0066] A robot simulation load test method, the test method is carried out with 5 sets of towing test benches, the servo driver 14 to be tested is electrically connected to 5 simulated robot motors 13. Steps include:

[0067] S1: giving a first instruction to the servo driver 14 to be tested, so as to simulate the robot to perform the first action.

[0068] S2: Obtain the theoretical position of each simulated robot motor 13 after performing the first action, and obtain 5 theoretical positions.

[0069] S3: Generate 5 first moments according to 5 theoretical positions.

[0070] S4: Command each load motor 11 to output at the corresponding first torque at the same time.

[0071] S5: Obtain the second torque measured by each torque sensor 12 to obtain 5 second torques.

[0072] S6: Simultaneously adjust the output of each load motor 11 until the difference between each second torque and the corresponding first torque is less than the allowable range.

[0073] S7: keep the si...

Embodiment 3

[0078] A robot simulation load testing method, the testing method is carried out with 6 sets of towing test benches, and the servo drive 14 to be tested is electrically connected to 6 simulation robot motors 13. Steps include:

[0079] S0: Obtain the shell weight of each axis of the robot and the weight of the servo motor of each axis of the robot.

[0080] S1: Issue a first instruction to the servo driver 14 to be tested to simulate the robot to perform the first action, wherein the first instruction is a speed instruction, and the steps of generating the first instruction include:

[0081] S11: Determine the joints simulated by the motors of each simulated robot.

[0082] S12: Calculate a number of motion speeds according to the first action combined with the simulated joints of each simulated robot motor. First of all, it is clear which axis of the robot is simulated by each simulated robot motor 13. After the first action is input in the industrial computer 18, the indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com