Construction method for high-rise large-span stiff damping structure

A technology of damping structure and construction method, which is applied in building components, building structure, earthquake resistance, etc., can solve the problems that buildings cannot meet the requirements of functions, green environmental protection, economic and energy saving, the overall cost of buildings and the increase of renovation problems, etc. The effect of reducing the amount of steel and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

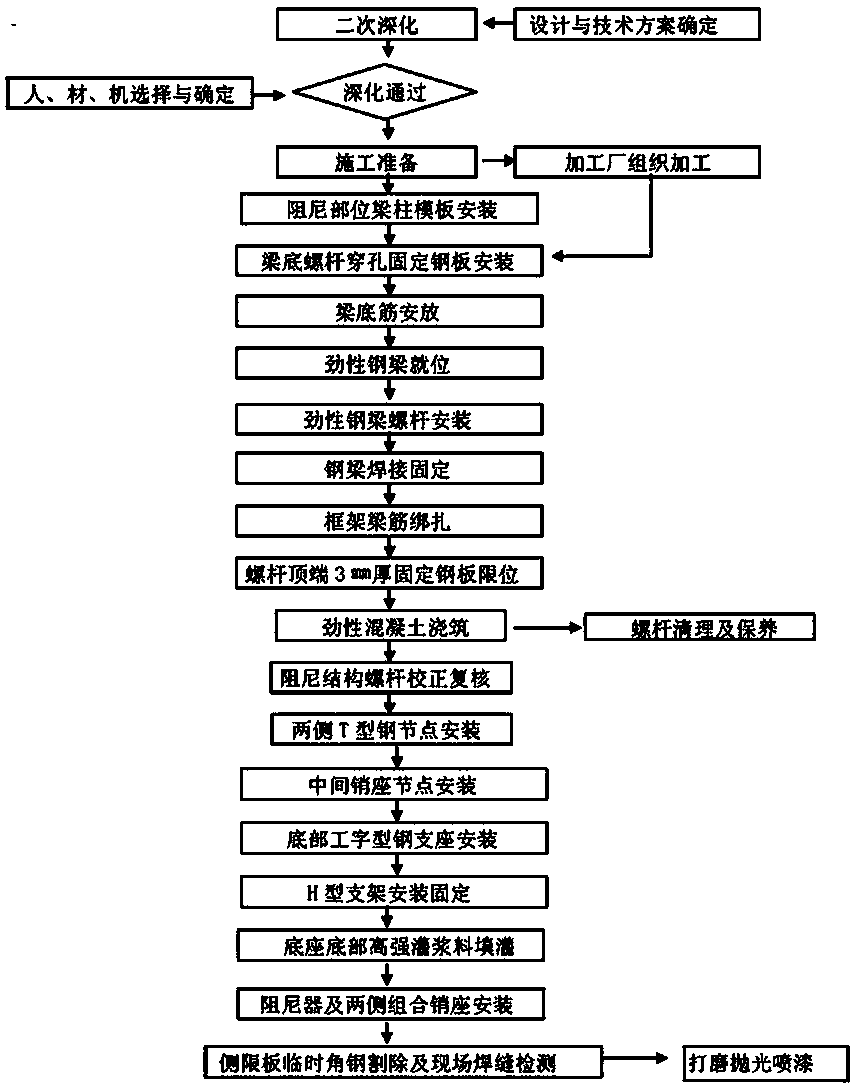

Image

Examples

Embodiment Construction

[0055] According to the principle of three holes and one line, the screw is accurately pre-embedded for damping and installing the screw at three levels of the rigid structure frame beam bottom, the upper and lower flange plates of the stiff steel beam, and the screw is perforated and positioned; and the screw is perforated and positioned at the top of the screw. Effectively control the reserved accuracy of the screw at the bottom of the beam and the floor; after the screw is corrected in place, the stiff steel beam is welded to the frame column and the embedded parts at the end of the column; the height of the damping structure is reduced by 50mm through the second deepening design and carried out The components are disassembled and processed uniformly in the manufacturer. The damping structure installs each deepening component through the screw reserved for the rigid structure, and the pin seat nodes, brackets, dampers, and bases of the damping structure are installed in place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com