Installation method of two-story steel structure in large-area enclosed workshops

An installation method and technology of a two-story structure, which are applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of inability to install tower cranes on the roof, low bearing capacity of factory building panels, transportation and installation problems, etc. The effect of shortening the installation period, self-weight and small size, and saving hoisting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

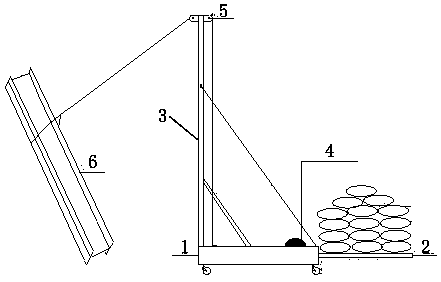

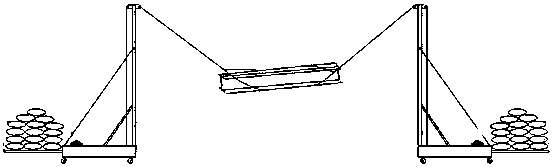

[0013] Such as figure 1 Shown is a method for installing a two-story steel structure of a large-area closed factory building, which includes:

[0014] Step 1, according to the height of the two-story structure, the span and the scale of steel beams and steel columns, a kind of one-arm hoisting hoisting vehicle is produced, and the one-arm hoisting hoisting vehicle includes: a vehicle seat 1 for loading rollers below, a vehicle seat rear The counterweight area 2, the vertical rod 3 provided on the vehicle seat, the electric winch 4 and the pulley block 5 on the top of the vertical rod; end;

[0015] Step 2, transport the second-story steel structure to the installation site by the transport trolley, fasten the free end of the steel wire rope of the hoisting vehicle with the counterweight to the steel structure 6;

[0016] Step 3: Control the operation and lifting of the electric winch, and control the speed and positioning during the lifting process. After the steel column of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com