Barrel connecting method without support

A connection method and unsupported technology, which is applied in the installation field of the rotary kiln shell, can solve the problems of high installation cost, increased construction period and installation cost, and failure to meet the requirements of installation period and installation cost control, so as to save labor, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

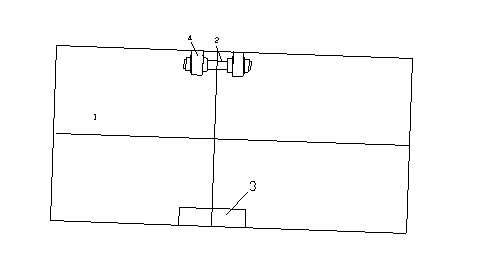

[0012] Such as figure 1 As shown, an unsupported cylinder connection method, which includes the following steps:

[0013] Step 1, Segmentation of the cylinder body and positioning of the connection points: After the cylinder body 1 is transported to the site, the cylinder circle is segmented according to the number of tension bolts and lap plates installed, and the welding of tension bolts 2 and lap plates 3 is fixed Location;

[0014] Step 2, welding the tension bolt seat; welding the tension bolt seat 4 on one of the two cylinder bodies to be connected according to the pre-determined position, each welding seam only welds the tension bolt seat on one side;

[0015] Step 3, cylinder connection; after the cylinder is hoisted, after the two sections of the cylinder are hoisted and docked, use the tension bolt 2 to locate the welding position of the other bolt seat, and weld it, and then fix the tension bolt through the two bolt seats. Then weld the lap joint plate at the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com