Mudflat wind electric field fan foundation structure

A technology for fan foundations and wind farms, which is applied in infrastructure engineering, underwater structures, water conservancy projects, etc., can solve the problems of long construction period and large amount of soil, and achieves low hoisting cost, reduced construction difficulty, and small hoisting height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

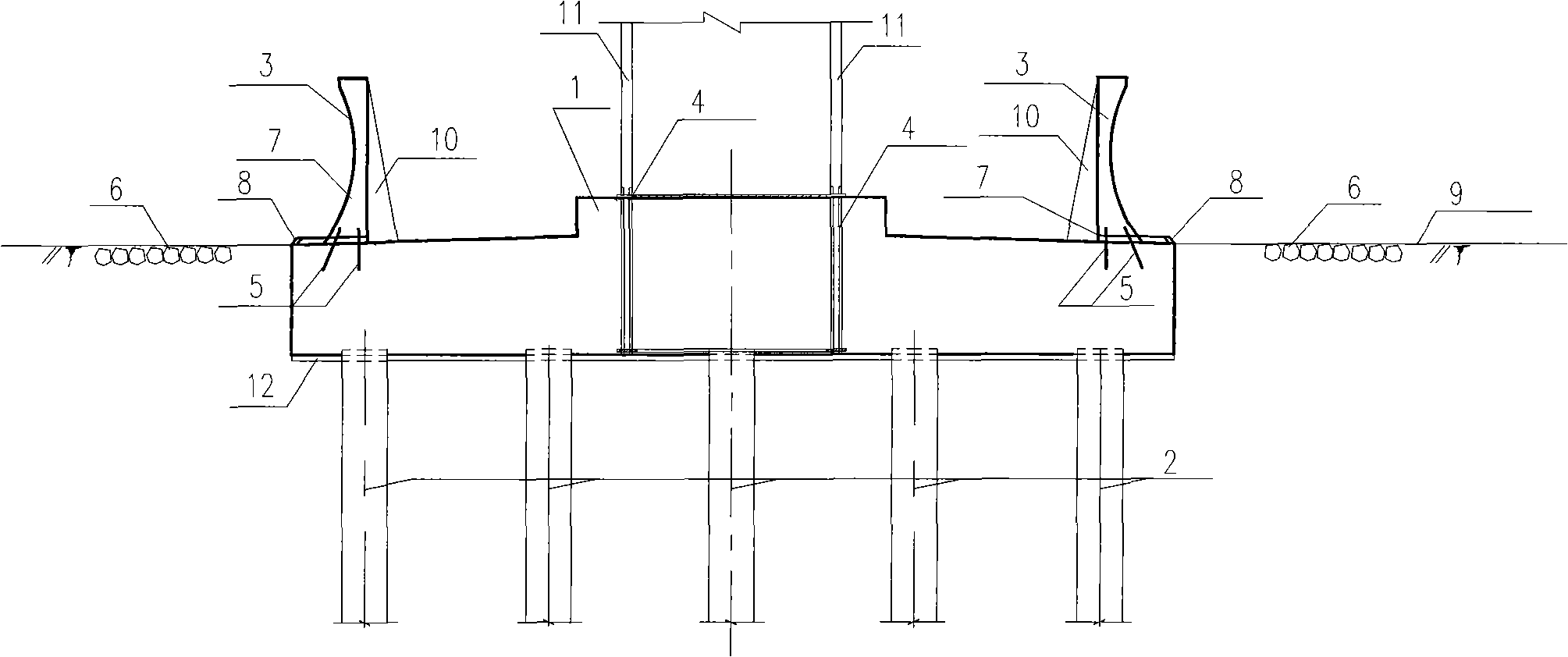

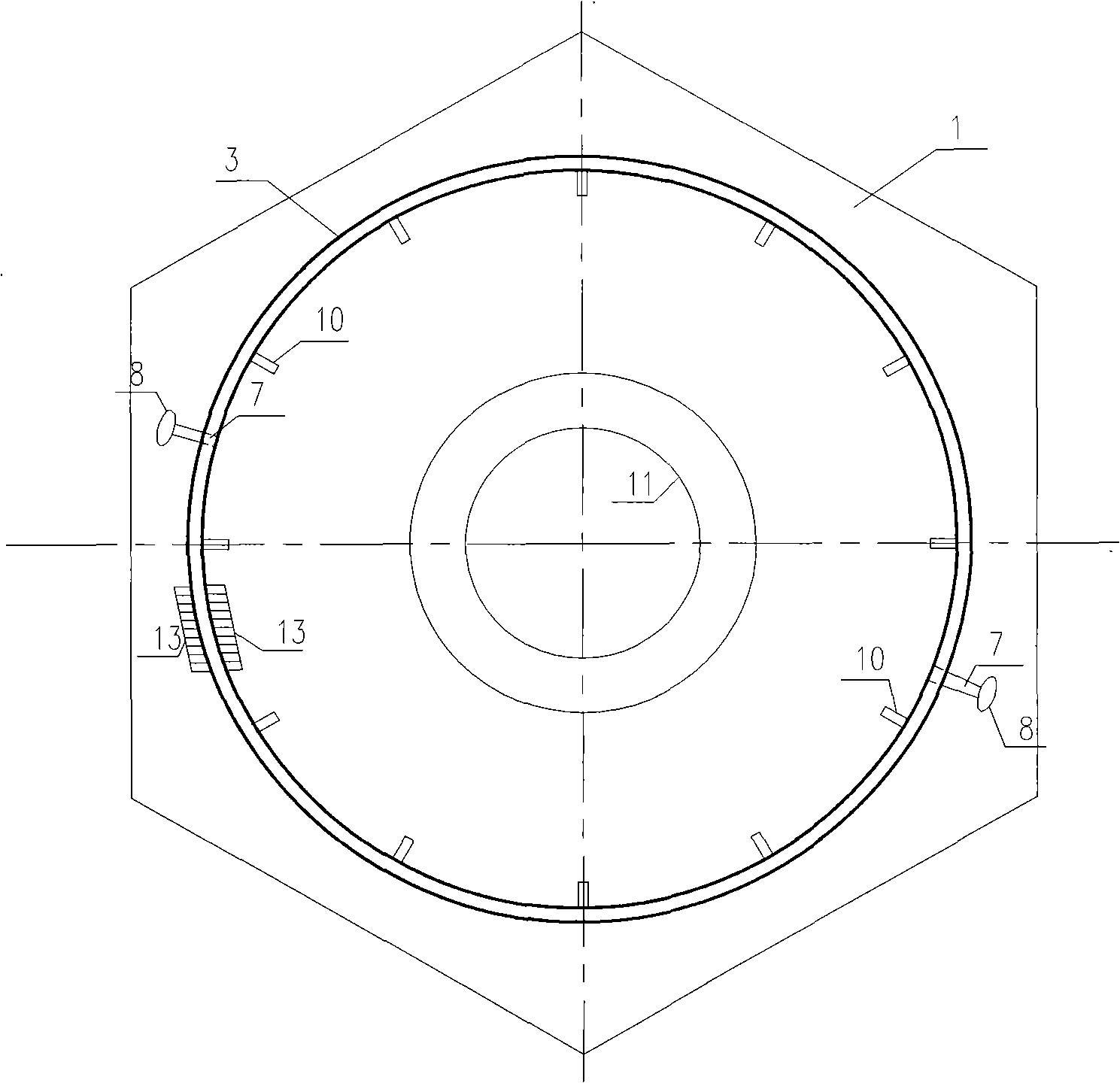

[0015] A tidal flat wind farm fan base structure, such as figure 1 , 2 As shown in the figure:

[0016] 1. Reinforced concrete foundation, 2. Pile foundation, 3. Wave wall, 4. Embedded parts of fan tower, 5. Reinforcement reserved for wave wall, 6. Anti-scour facilities, 7. Drainage groove, 8. One-way Valve, 9. Tidal flat surface, 10. Rib, 11. Fan tower tube, 12. Foundation cushion, 13. Ladder.

[0017] Taking the tidal flat wind farm site as an example with weak foundation soil, the reinforced concrete foundation 1 generally requires the establishment of a pile foundation 2, and the lower part of the reinforced concrete foundation 1 should be paved with the foundation cushion 12 first, and the wind tower should be erected before the reinforced concrete foundation 1 is poured. Frame pre-embedded parts 4, fan tower pre-embedded parts 4 are connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com