Longitudinal assembly type prestressed bent cap

A technology of transverse prestressing and prestressing, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as potential safety hazards, weak joints of beam segments, and high hoisting costs, so as to save hoisting costs and improve the structure Bearing capacity and seismic performance, the effect of reducing hoisting batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

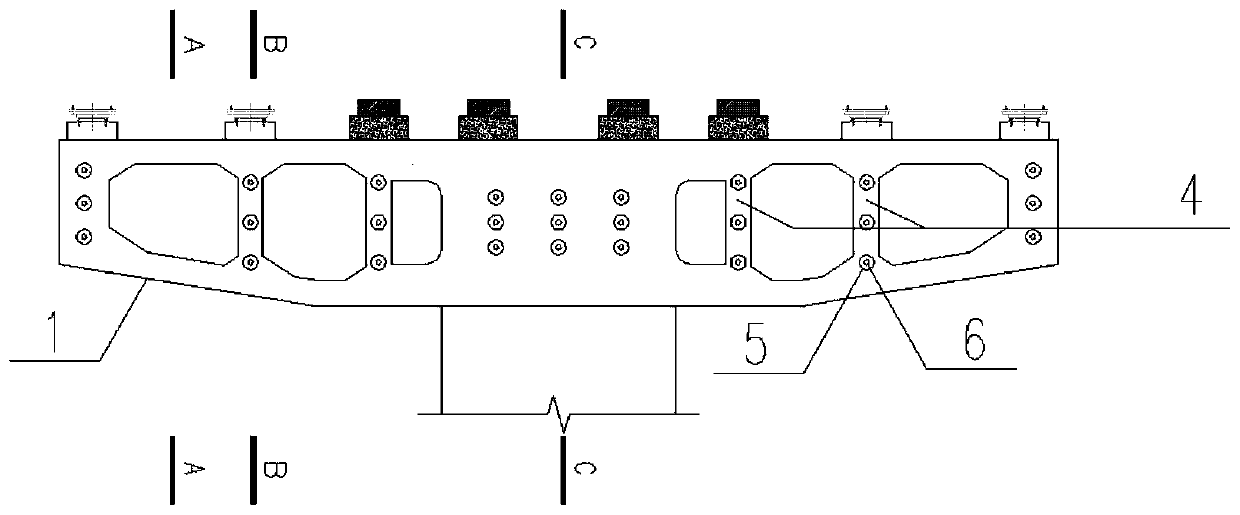

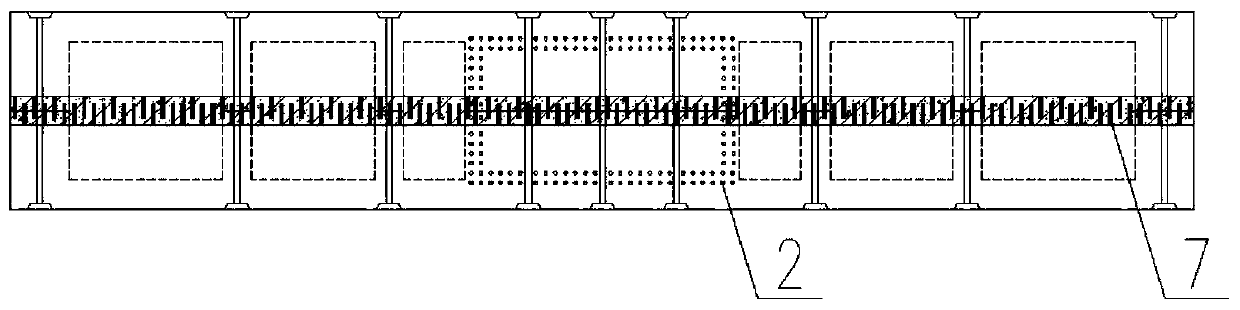

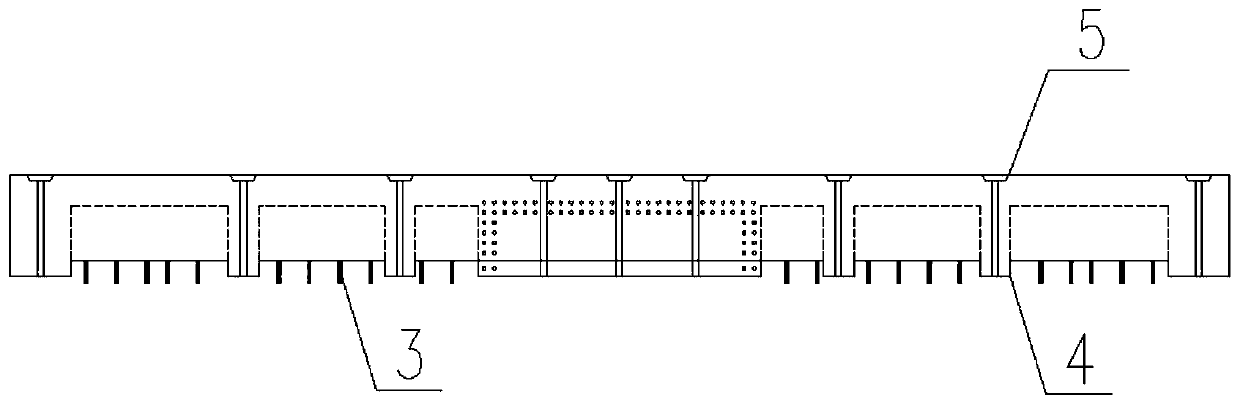

[0021] Such as Figure 1 to Figure 6 As shown, a longitudinally assembled prestressed cover beam of the present invention includes two prestressed cover beam prefabricated assemblies 1 arranged symmetrically along the centerline of the longitudinal direction of the beam; small area. The prestressed cover beam prefabricated component 1 is provided with the reserved hole 2 for the main reinforcement of the pier column within the range of the node area at the top of the pier column. The reserved hole 2 for the main reinforcement of the pier column is arranged according to the reinforcement result of the pier column to ensure accurate positioning; 1. The cantilever part adopts C-shaped section, and the two prestressed cover beam prefabricated components are symmetrically assembled to form a cavity inside the cover beam, which greatly reduces the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com